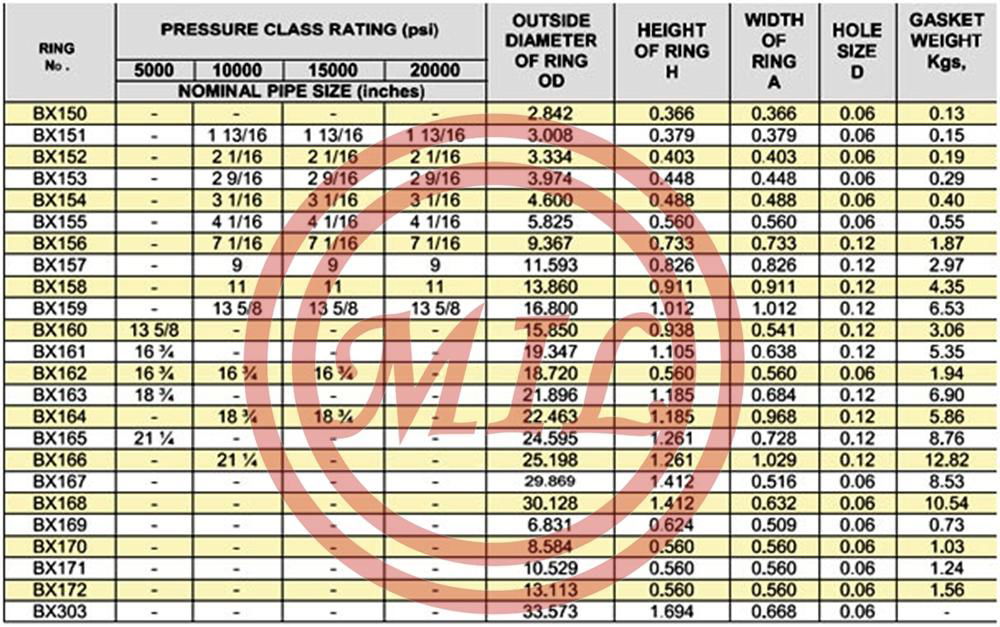

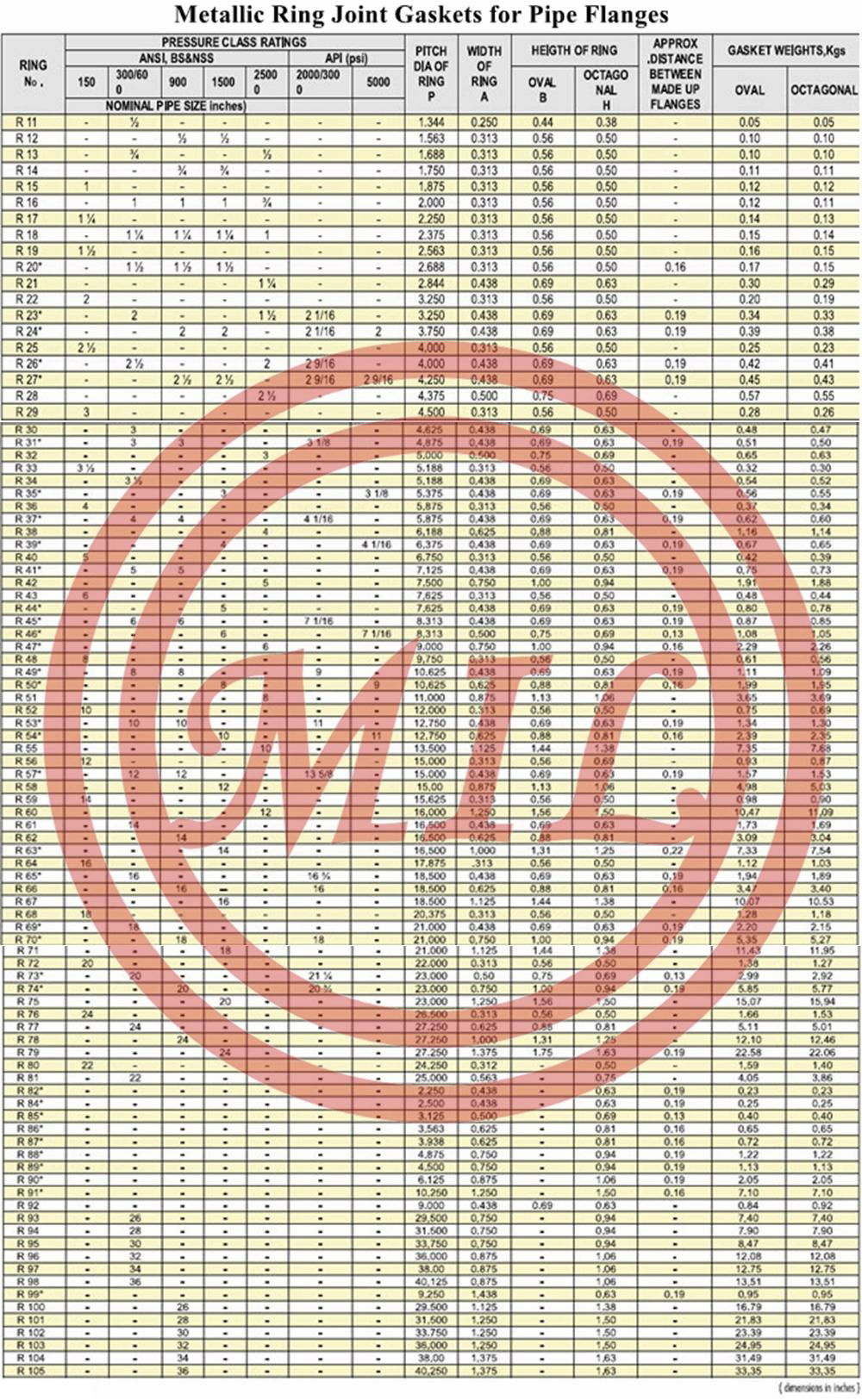

| Metallic |

Ring Joint Gaskets |

Carbon Steel, Stainless Steel, Duplex/ Super Duplex, Nickel, Hastelloy and Inconel |

A285 Gr.C, ASTM A240 TP304/304L, TP316/316L, SS316Ti, 321, 347, F51, F53, F55, F57, F60, Nickel 200, Hastelloy B & C, Inconel 600, 625 & Incoloy 800, 825 |

1/2”- 60” |

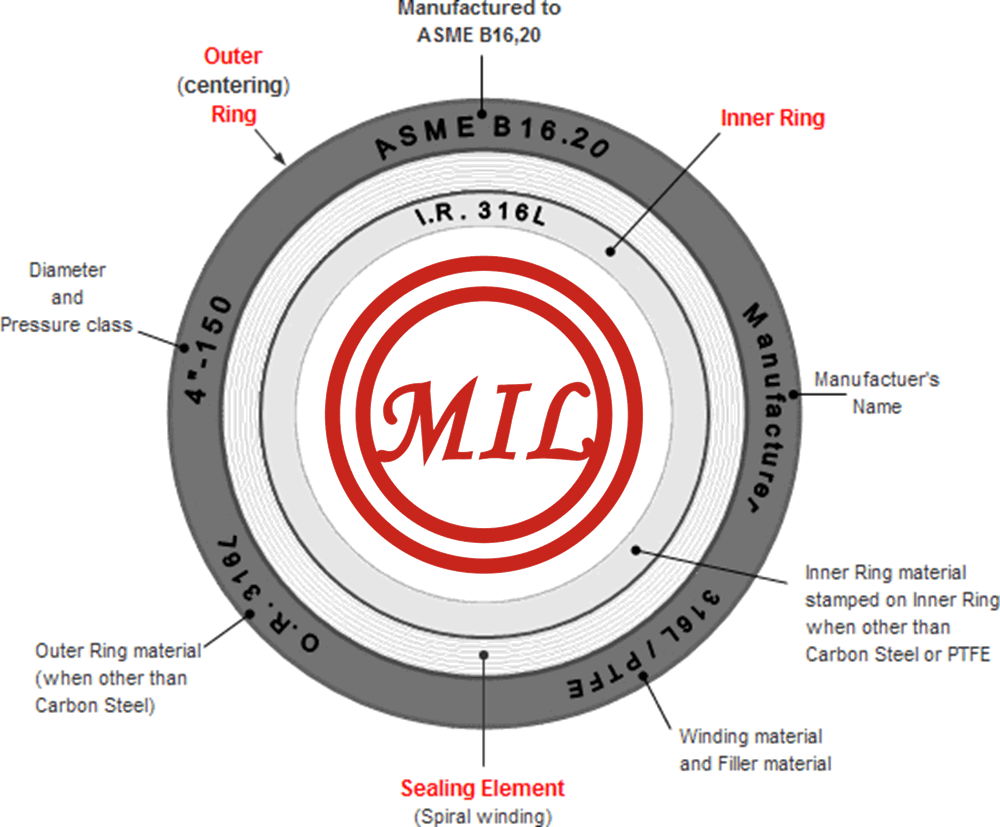

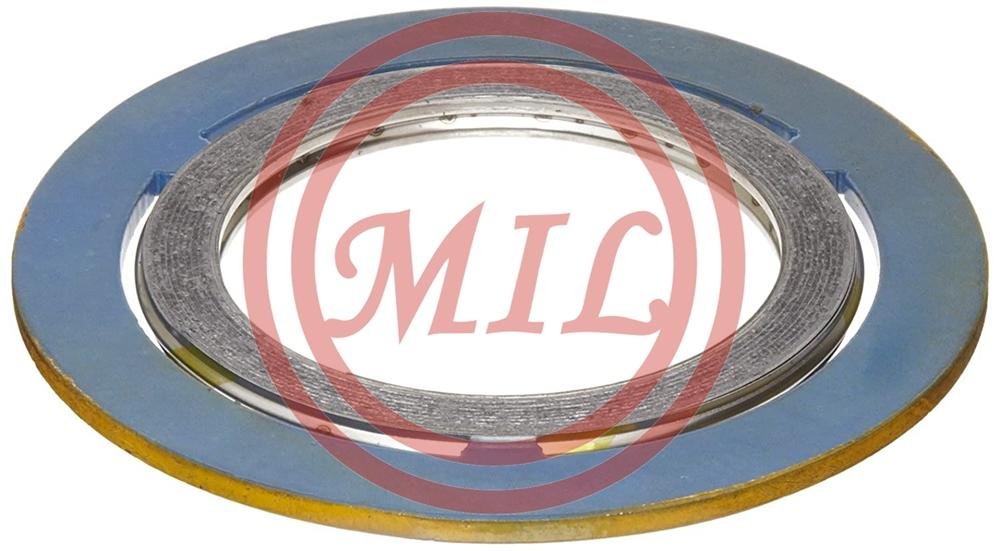

| Spiral Wound Gaskets (SPW) |

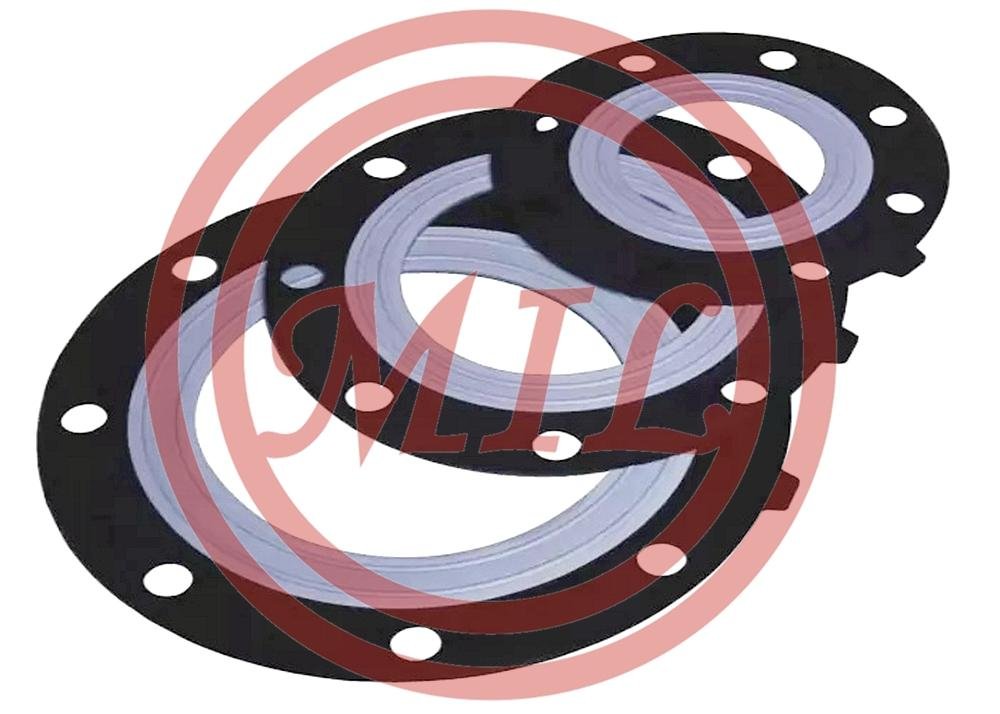

| Non-Metallic |

Flat Cut Gaskets, Elastomers & Sheet products, Braided Gaskets |

PTFE Sheet, Aramid Fibre, Glass Fibre, Elastomers, Graphite |

PTFE.Carbon Fibre, Glass Fibre, Synthetic Fibre, Aramid Fibre, Neoprene, Nitrile, EPDM |

| Flange Insulation Kits |

Type RF/F, Type FF/E, Type RTJ/D |

Nitrile, Phenolic, Integral, Mylar, Polyethylene, Non- Asbestos |

Nitrile, Phenolic, Integral, Mylar, Polyethylene, Non- Asbestos, PTFE, EPDM , VITON |