Product Description

Glass Reinforced Polyester/Epoxy Pipes (GRP/GRE)

GRP Pipes or Glass Reinforced Plastics pipes are composite material pipes consisting of a polymer matrix that is reinforced with glass fibers. They have very high corrosion resistance ability and thus used widely for low-temperature corrosion-resistant applications. GRP Pipes and FRP Pipes (GRP and FRP acronyms) is used interchangeably in the fiber glass pipe industry. The difference is that the FRP Pipes acronym is primarily used in the United States and Canada while most other countries use the term GRP Pipes.

GRP Family

• GRP: Glass – fibre reinforced plastic.

• GRE: Glass – fibre reinforced epoxy.

• GRV: Glass – fibre vinyl ester.

• GRUP: Glass – fibre reinforced unsaturated polyester.

The different types of pipes are selected according to the required properties like chemical resistance, temperature resistance, and mechanical properties.

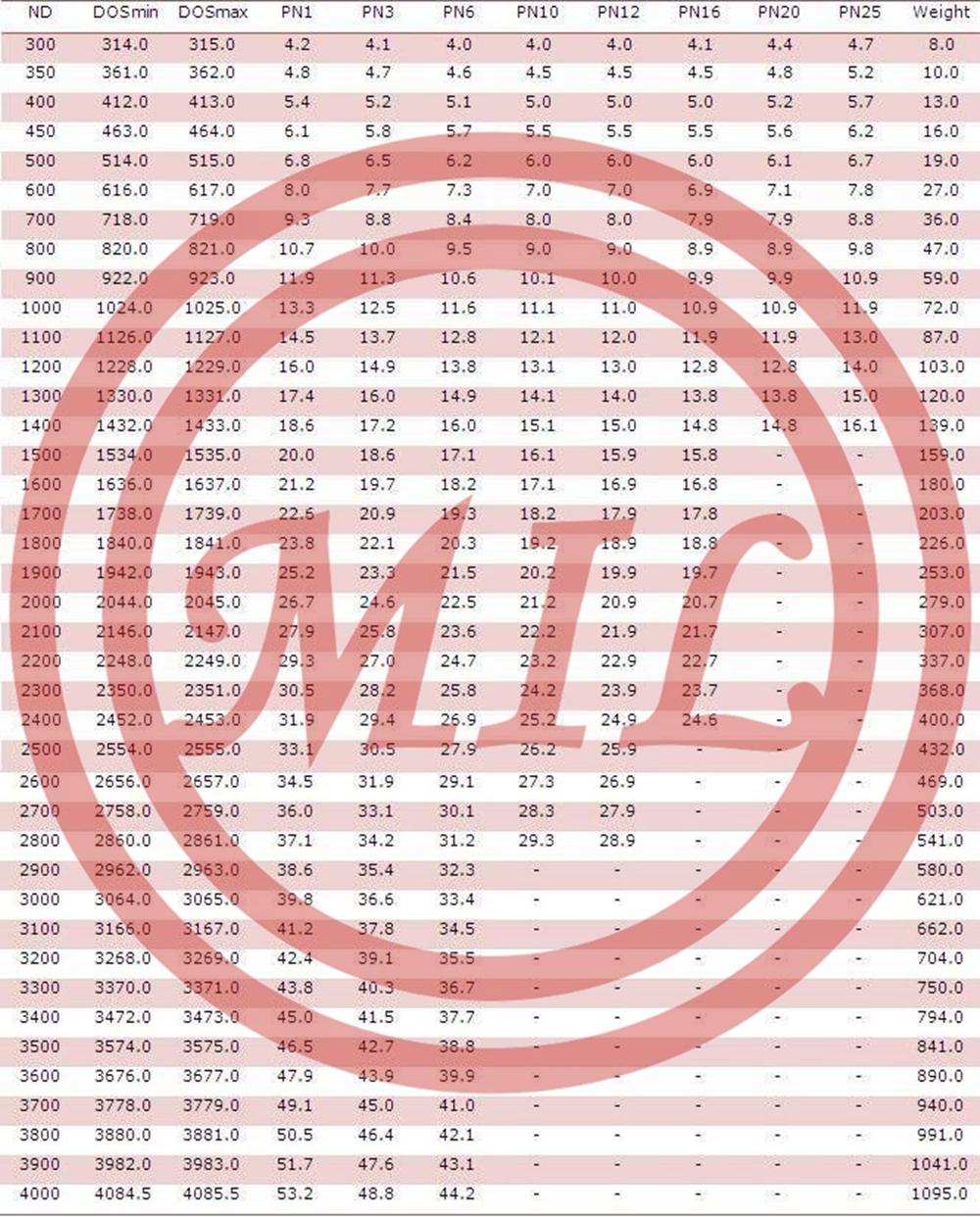

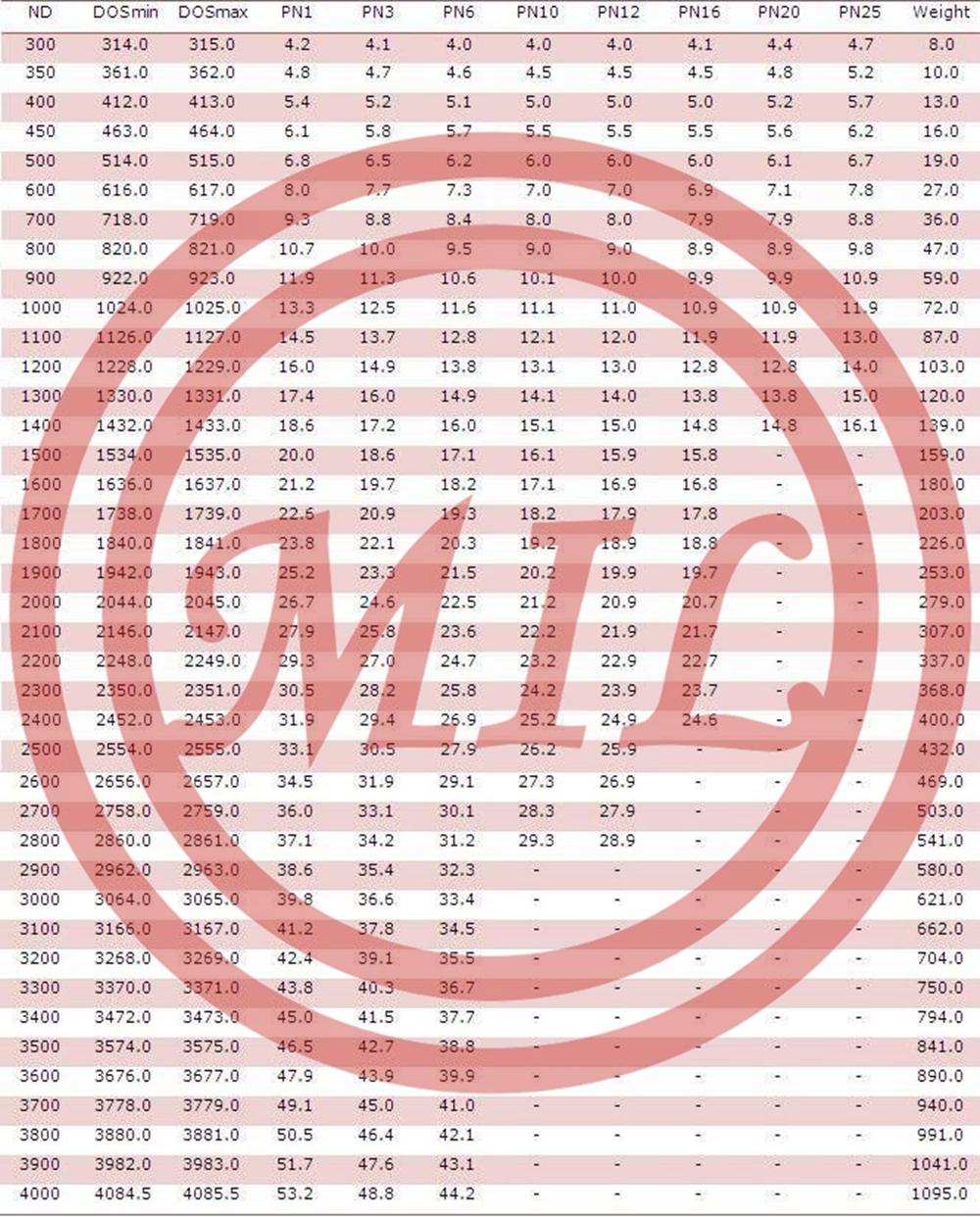

Physical Properties

Nominal Diameter [DN] 10 - 4000 mm

Nominal Pressure [PN] up to 32 bar

Nominal Stiffness [SN] up to 20000 N/m²

Types of Manufacturing of GRP Pipes

• Filament winding.

• Centrifuge

• Continuous winding or Drostholm Method.

• Helical Filament winding

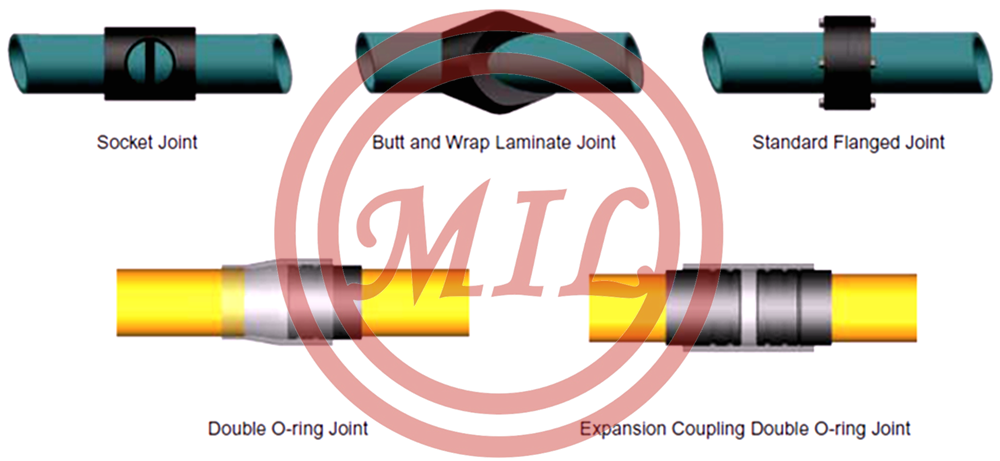

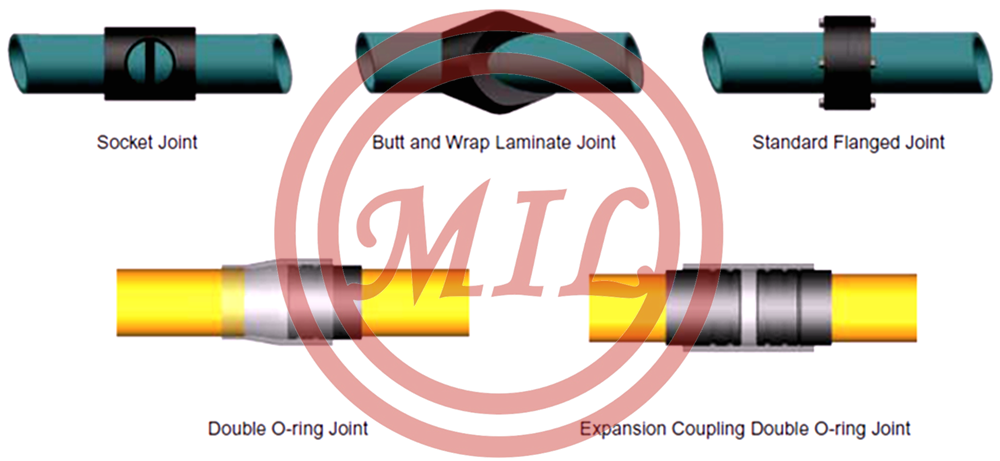

GRP Pipe Connections

• Adhesive Joint

• Flange Joint

• Lamination Joint

• Rubber Seal Lock Joint

Characteristics of GRP Pipe

• Corrosion resistance: Corrosion resistant to both inside and outside corrosion. As a result, additional linings and exterior coatings are not required.

• When the ratio of strength per unit of weight is considered, fibreglass composites surpass CS and SS.

• Lightweight: Fibreglass piping is only one-sixth the weight of steel products and 10% the weight of similar concrete products.

• Electrical properties: Standard fibreglass pipes are nonconductive. Some manufacturers offer conductive fibreglass piping system for transporting fluids like Jet Fuel.

• Dimensional stability: Fibreglass material meets the most stringent material stiffness, dimensional tolerance, weight and cost criteria.

• Low maintenance cost: Fibreglass piping is easy to maintain because it does not rust, is easily cleaned and requires minimal protection from the environment.

Advantages of GRP Pipes

• Long life; highly durable.

• Low maintenance cost.

• High Corrosion resistance.

• Low lifecycle cost.

• No need for cathodic protection.

• Less transportation and handling cost.

• Environmental friendly.

• Wide application range.

• Economic when compared with DSS pipe (Duplex stainless steel)

Reference Standards:

- AWWA C950 Glass Fibre Reinforced Thermosetting Resin Pressure

- ASTM D2996 Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

- ASTM D2310 Machine-Made "Fibreglass" (Glass-Fibre-Reinforced Thermosetting-Resin) Pipe

- ASTM-D3262 “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Sewer Pipe

- ASTM D3517 ‘Fibreglass” (Glass-Fibre-Reinforced Thermosetting -Resin) Pipe

- ASTM D3754 “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin Sewer and Industrial Pressure Pipe

- ASTM D4161 “Fibreglass” (Glass-Fibre-Reinforced Thermosetting - Resin) Pipe Joints Using FlexibleElastomeric Seals

- ASTM D4024 Machine Made “Fiberglass” (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

- ASTM D5685 “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pressure Pipe Fittings

- BS 5480 Glass Reinforced Plastics (GRP) Pipes, Joints and Fittings for Use for Water Supply or Sewerage

- CSA Z662 Oil & gas pipeline systems

- DIN 16868 Glass fibre reinforced unsaturated polyester resin (UP-GF) pipes

- DIN 16869 Centrifugally cast filled glass fibre reinforced unsaturated polyester resin (UP-GF) pipes;

- EN 705 Plastics piping systems - Glass-reinforced thermosetting plastics (GRP) pipes and fittings - Methods for regression analyses and their use;

- EN 1115 Plastics piping systems for underground drainage and sewerage under pressure - Glass-reinforced thermosetting plastics (GRP) based on unsaturated polyester resin (UP);

- EN 1796 Plastics piping systems for water supply with or without pressure – Glassfiber reinforced thermosetting plastics (GRP) based on unsaturated polyester resin (UP)

- EN 14364 Plastics piping systems for drainage and sewerage with or without pressure – Glassfiber reinforced thermosetting plastics (GRP) based on unsaturated polyester resin (UP) – Specifications for pipes, fittings and joints

- ISO 10467 Plastics piping systems for pressure and non-pressure drainage and sewerage – Glassfiber reinforced plastics (GRP) systems based on unsaturated polyester (UP) resin

- ISO 10639 Plastics piping systems for pressure and non-pressure water supply-Glass reinforced thermosetting plastics (GRP) systems based on unsaturated polyester (UP) resin

- ISO 14692 Petroleum and natural gas industries-Glass-reinforced plastics (GRP) piping

- ISO 25780 Plastics piping systems for pressure and non-pressure water supply, irrigation, drainage or sewerage – Glass-reinforced thermosetting plastics (GRP) systems based on unsaturated polyester (UP) resin – Pipes with flexible joints intended to be installed using jacking techniques

Product Image