Product Description

PP-R pipe.also called random copolymerized polypropylene (type Ⅲ)pipe,is a new generation of environment-friendly construction material developed in the 1990s.Besides plastic pipes' merits such as lightness.corrosion resistance.anti-deposition and long service life.PP-R piipe also enjoy some other advantages,like hygienicness,heatresistance and longer service life.Meanwhile,its coefficient of heat conductivity is quite low and it is good at heat preservation and energy conservation.Because of the technique of thermosol binding,it is convenient to be installed and reliable in joints.Also,the material can be recycled.Therefore,it is worthy of the name environment-friendly construction material.

Compared with aluminum multiunit pipe,PP-R pipe can be made into tubular products with larger calibers,with the largest reaching more than 163mms in caliber.Mingda PP-R pipes and pipe fittings are widely used in such areas as delivery of drinking water,production and delivery system of purified water and drinks,transportation of chemical fluids,heating pipes,circulation system of hot water,pipes in agriculture,planting in gardens,parks and ranches,etc.

PPR Fiber-glass(FR-PPR) composite pipes make use of 100% mported raw materials,and thus guarantee its product quality. This high-performance pipe is produced through multi-layer co-extrusion at low temperature and high speed by special technique and equipent.This pipe has 3 layers,in which the internal and external layer is made of PP-R materials,while the middle layer is stiffened and rein forced composite materials.PP-R materials of internal layer ensure the hygiene of this pipe;the middle layer stiffens and reinforced this pipe,and reduces coefficient of linear expansion;PP-R materials of external layer facilitate its hot-melting and socket connection with teaditional PP-R pipes.This pipe is equipped with 5 series of pressure class,including S2,S2.5,S4andS5,which are designed of hot water conveying system.Its nominal outside diameter has over 10 specitications,which ranges from 20 mm to 63 mm.

Aluminum-plastic PP-R composite pipe comprises of five-layer mutual-extruded structure,interior layer is food degree PE-RT(PE),exterior layout is of PP-R,middle one is of longitudinal superposition-welded aluminum layer,which isolates each kind of liquid from penetration.It integrates in excellent high-temperature resistant performance for aluminum-plastic composite pipe and less distortion after heated while having reliability for PP-R tubing thermal melting connection.so it preferably settles down shortcoming of higher cost for aluminum-plastic composite tube joint and more linear expandability coefficient for PP-R tubing,its connection is the same as that of PP-R tubing.

The stable random copolymerized polypropylene pipe(stable PP-R pipe) for short)is a kind of latest environment-friendly composite tube,which is made up of a metal tube and a series of protective layers fixed together by specialized hot colloidal PERFORMANCE ATTRIBUTES

1.The coefficient of thermal expansion of it is 1/3 that of the common PP-R tube,and it will not be distorted by the long period of exposure to hot water.

2.The Aluminum and the plastic are fixed tightly,whichrenders it uviofast and ensures a longer longetivity.

3.It adopts the homogeneous connection by hot colloidal sols and is conveniently fixed,reliable and timesaving.

4.It is hygienic and innocuous.It meets the standard of GB/T17219-1998 and is qualified for a type of environment-friendly product.

|

PPR TUBING

|

PN 2.0MPa

|

PN 2.5MPa

|

|

Outer Diameter

dn(mm)

|

Wall Thickness

en(mm)

|

Wall Thickness

en(mm)

|

|

20

|

2.8

|

3.4

|

|

25

|

3.5

|

4.2

|

|

32

|

4.4

|

5.4

|

|

40

|

5.5

|

6.7

|

|

50

|

6.9

|

8.4

|

|

63

|

8.7

|

10.5

|

|

75

|

10.3

|

12.5

|

|

90

|

12.3

|

15.0

|

|

110

|

15.1

|

18.3

|

|

160

|

21.7

|

26.6

|

| Standards for PE pressure piping systems |

| |

|

| ISO 4427-1 |

Plastics piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE) – Part 1: General |

| ISO 4427-2 |

Plastics piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE) – Part 2: Pipes |

| ISO 4427-3 |

Plastics piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE) – Part 3: Fittings |

| ISO 4427-5 |

Plastics piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE) – Part 5: Fitness for purpose of the system |

| ISO 4437-1 |

Plastics piping systems for the supply of gaseous fuels – Polyethylene (PE) – Part 1: General |

| ISO 4437-2 |

Plastics piping systems for the supply of gaseous fuels – Polyethylene (PE) – Part 2: Pipes |

| ISO 4437-3 |

Plastics piping systems for the supply of gaseous fuels – Polyethylene (PE) – Part 3: Fittings |

| ISO 4437-4 |

Plastics piping systems for the supply of gaseous fuels – Polyethylene (PE) – Part 4: Valves |

| ISO 4437-5 |

Plastics piping systems for the supply of gaseous fuels – Polyethylene (PE) – Part 5: Fitness for purpose of the system |

| EN 1555-1 |

Plastics piping systems for the supply of gaseous fuels –Polyethylene (PE) – Part 1: General |

| EN 1555-2 |

Plastics piping systems for the supply of gaseous fuels –Polyethylene (PE) – Part 2: Pipes |

| EN 1555-3 |

Plastics piping systems for the supply of gaseous fuels –Polyethylene (PE) – Part 3: Fittings |

| EN 1555-4 |

Plastics piping systems for the supply of gaseous fuels –Polyethylene (PE) – Part 4: Valves |

| EN 1555-5 |

Plastics piping systems for the supply of gaseous fuels –Polyethylene (PE) – Part 5: Fitness for purpose of the system |

| CEN/TS 1555-7 |

Plastics piping systems for the supply of gaseous fuels –Polyethylene (PE) – Part 7: Guidance for assessment of conformity |

| EN 12201-1 |

Plastics piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE) – Part 1: General |

| EN 12201-2 |

Plastics piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE) – Part 2: Pipes |

| EN 12201-3 |

Plastics piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE) – Part 3: Fittings |

| EN 12201-4 |

Plastics piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE) – Part 4: Valves |

| EN 12201-5 |

Plastics piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE) – Part 5: Fitness for purpose of the system |

| CEN/TS 12201-7 |

Plastics piping systems for water supply, and for drainage and sewerage under pressure – Polyethylene (PE) – Part 7: Guidance for assessment of conformity |

| ISO 9623 |

PE/metal and PP/metal adapter fittings for pipes for fluids under pressure – Design lengths and size of threads – Metric series |

| ISO 9624 |

Thermoplastics piping systems for fluids under pressure – Flange adapters and loose backing flanges – Mating dimensions |

| ISO 15494 |

Plastics piping systems for industrial applications – Polybutene (PB), polyethylene (PE), polyethylene of raised temperature resistance (PE-RT), crosslinked polyethylene (PE-X), polypropylene (PP) – Metric series for specifications for components and the system |

| ISO 17885 |

Plastics piping systems – Mechanical fittings for pressure piping systems – Specifications |

ISO 8772 Plastics piping systems for non-pressure underground drainage and sewerage — Polyethylene (PE);

EN 12666 Plastics piping systems for non-pressure underground drainage and sewerage - Polyethylene (PE);

EN 1519 Plastics piping systems for soil and waste discharge (low and high temperature) within the building structure - Polyethylene (PE);

EN ISO 15875 Plastics piping systems for hot and cold water installations - Crosslinked polyethylene (PE-X);

EN 1555 Plastics piping systems for the supply of gaseous fuels - Polyethylene (PE);

DIN 8074 Polyethylene (PE) - Pipes PE 80, PE 100 – Dimensions ;

DIN 8075 Polyethylene (PE) pipes - PE 80, PE 100 - General quality requirements, testing;

ISO 8773 Plastics piping systems for non-pressure underground drainage and sewerage — Polypropylene (PP);

EN 1852 Plastics piping systems for non-pressure underground drainage and sewerage - Polypropylene (PP);

EN 10284 Malleable cast iron fittings with compression ends for polyethylene (PE) piping systems.

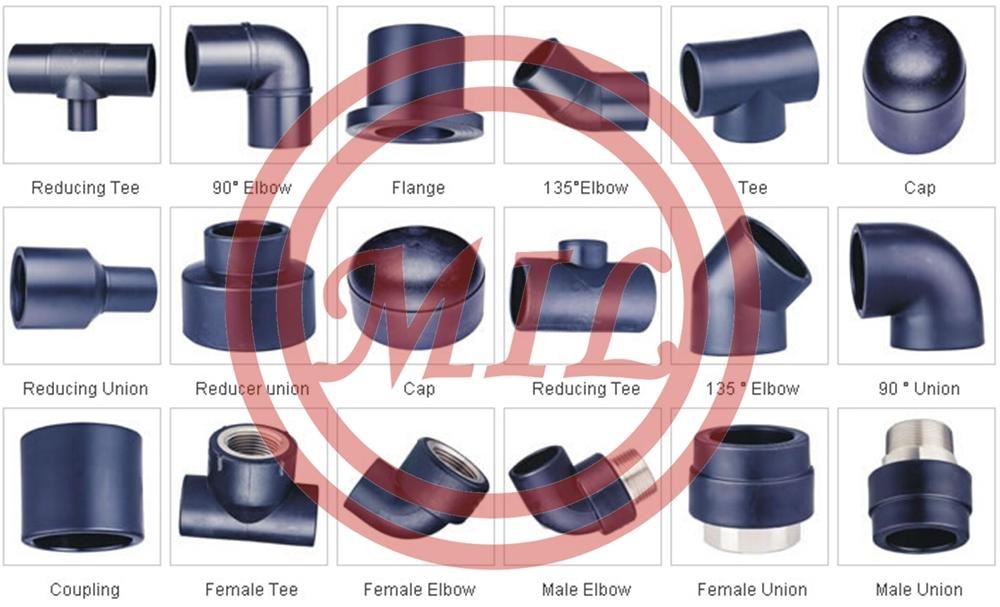

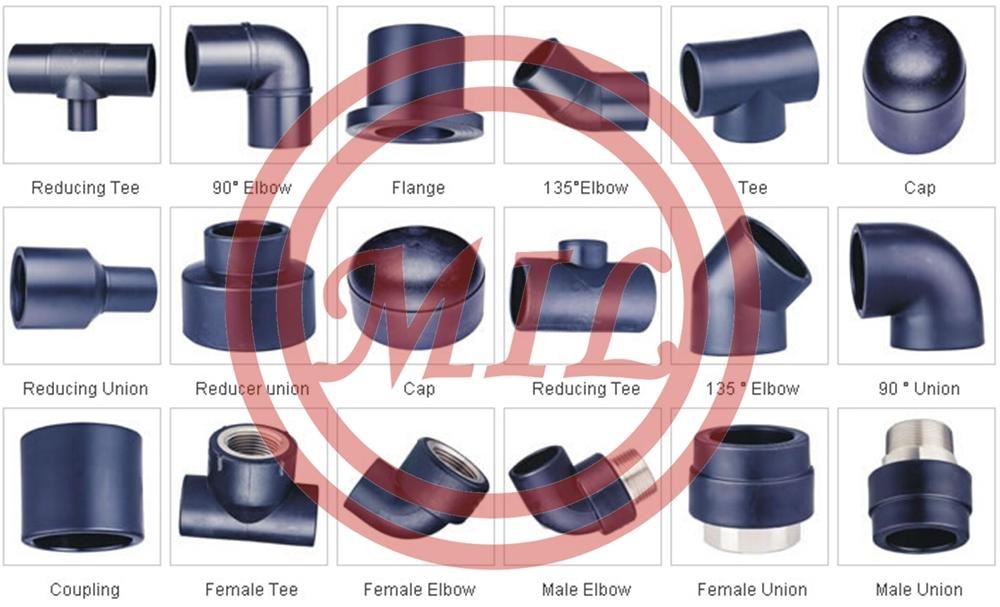

Product Image