Product Description

PIPE PILES WITH INTERLOCK

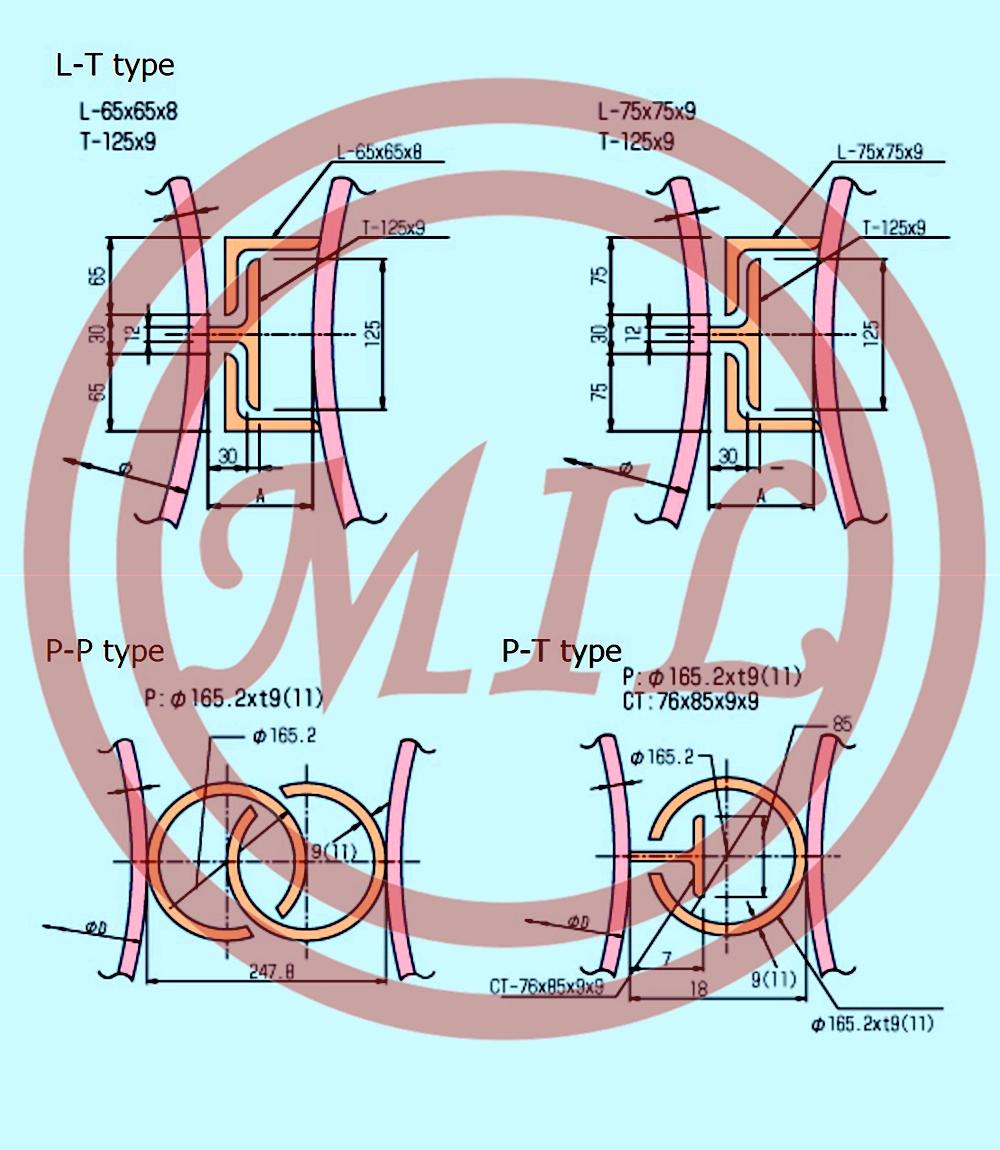

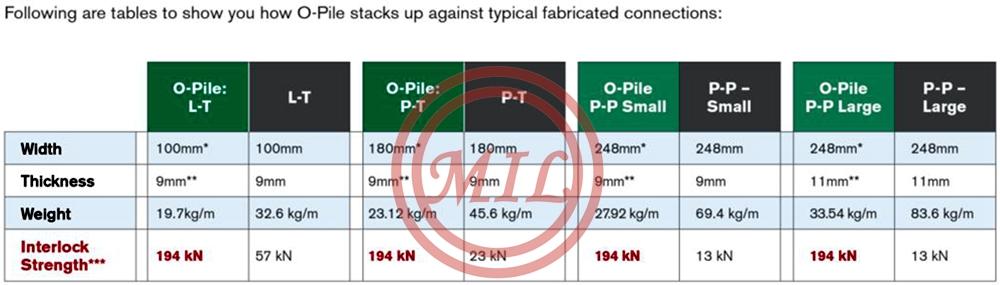

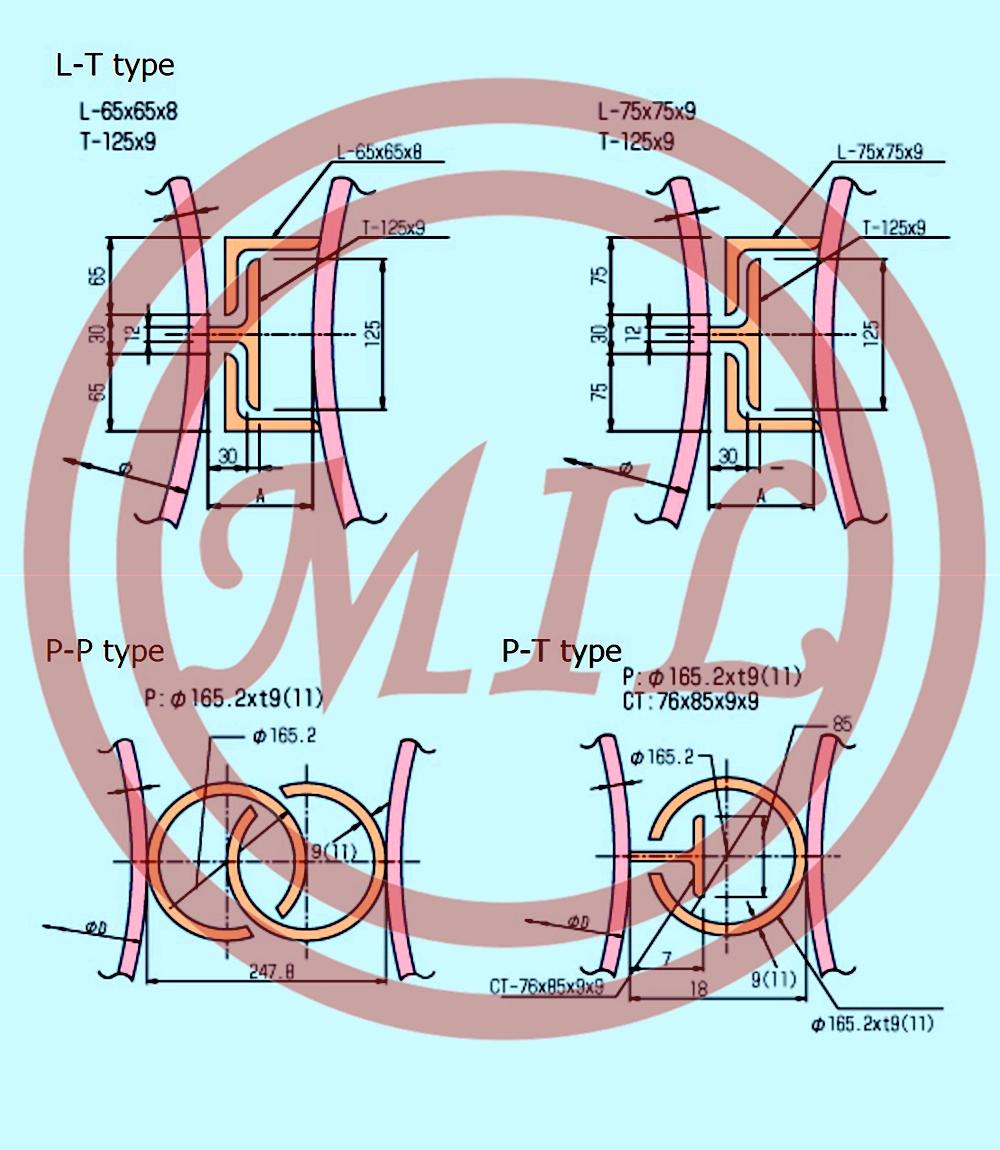

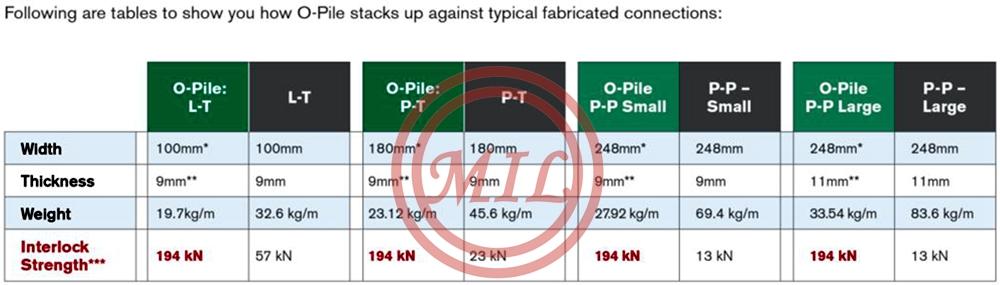

Combi-Wall Steel pipe pile joints are available in three types: P-P, L-T and P-T. You can choose joint designs to suit your applications, whether for revetment structures, bridge foundations, cofferdam walls or retaining walls. The P-P type, in particular, can deliver superior cut-off performance through use of a waterstop treatment.

1. Application:

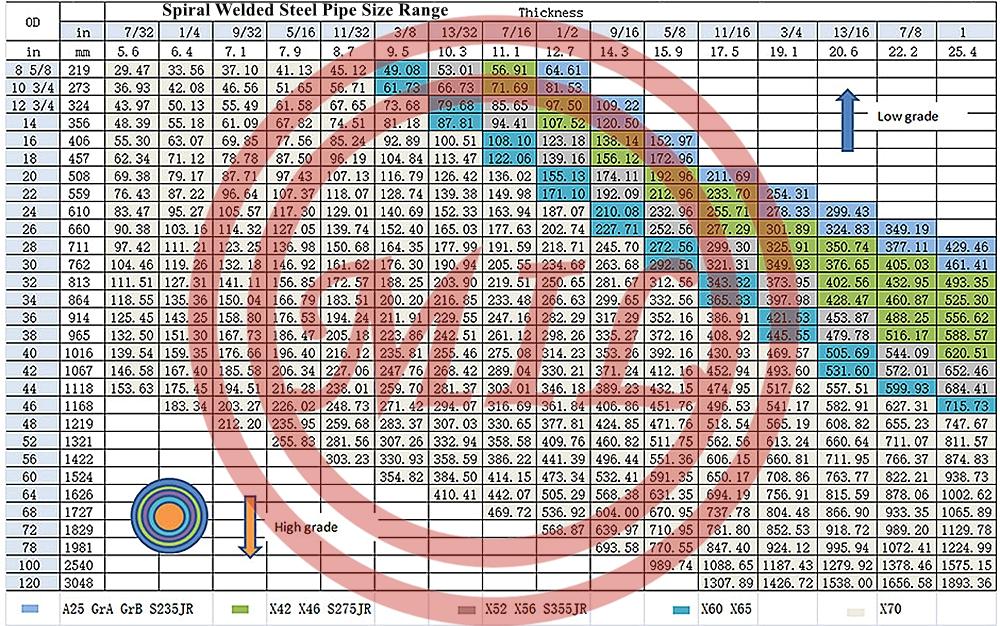

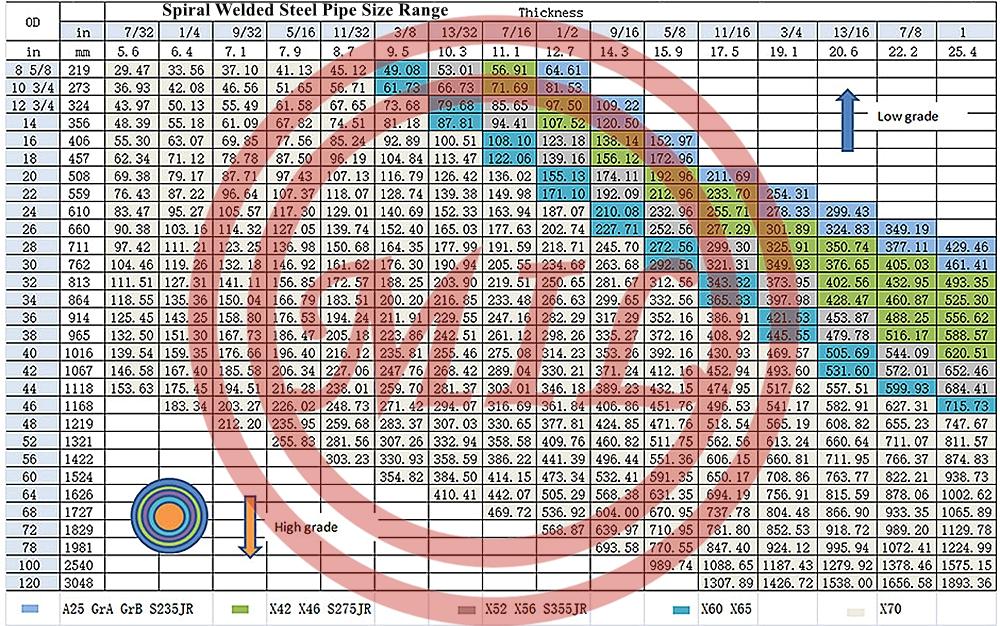

Pipe piles are produced from different steel grade for wide applications, for example, foundation pipes, king pile, monopile, bearing pile, pipe pile wall, slope stabilization, pipelines, deep foundation, and struts etc.

Complex Fabrications

Sheet pile interlocks

Factory made L& T clutches

Small pipe connectors

Sheet pile welded on pipes

Pipe driving shoes

For floating fenders

For pipe-pipe combiwall

Interior and exterior weld beading

Lifting holes

Shear rings

End covers

Additional modifications (brackets, tongue plates etc) also available

ACCESSORIES

Chill Rings

A chill ring includes a cylindrical non-consumable base metal ring having an outside diameter sized to fit adequately inside the diameter of the pipe end to be welded.

Conical Points

Conical points are used to push the earth aside and maintain grinding. On rough surfaces, the point distributes the load around the entire pipe, rather than focusing the shock on only a section.

Cutting Shoes

A open-end cutting shoe is an exceptionally tough, heat-treated cast steel shoe with a ledge to ease driving. Use of a cutting shoe protects the pipe end and makes it possible to use a thinner pipe.

Pipe Caps

Pipe caps are available in all standard sizes ranging from 8 5/8" to 72".

Pipe Splicers

Pipe piling splicers are available in all pipe sizes. Pipe splicers help ease alignment of pipe and drive it with no welding required.

2.Specification:

API 2B Specification for the Fabrication of Structural Steel Pipe- ASTM 572 Gr.50, EH36TM, DH36, DH36TMZ

API 5L PSL1/PSL 2 Line Pipe: Gr. B X42, X46, X52, X56, X60, X65, X70, X80/BM.X42M,X46M,X52M,X60M,X65M,X70,X80M

AS 1163 Structural Steel Hollow Sections-C250,C250L0,C350,C350L0,C450,C450L0

AS 1579 Arc-welded steel pipes and fittings for the piling purpose

ASTM A135 Standard Specification for Electric-Resistance-Welded Steel Pipe

ASTM A139 CHIMNEYS AND VENTILATION DUCTS for air and dust filtering systems, and smoke evacuation, PILLARS for ski chair-lifts and bridges

ASTM A252 FOUNDATION PILES for soil consolidation, marine wharfs-Grade 1,2,3ASTM A500 Standard Specification for Cold-Formed Welded and Seamless Carbon Steel Structural Tubing in Rounds and Shapes

BS 3601 Steel Pipe and Tubes for Pressure Proposes Carbon Steel: Ordinary Duties- Gr. 360,Gr. 430,

BS 7191 All Specification for Weldable Structure Steels for Fixed Offshore Structures

CSA Z245.1 Steel Pipe- Category I, II, III-241,290,359,386,414,448,483,550,620,690,825

DIN 1626 Welded circular tubes of non-alloy steel with special quality requirements-St. 37.0,St44.0, St.52.0

EN 10219-1 Cold formed welded structural hollow sections of non-alloy and fine grain steels-S275,S275J0H,S275J2H,S355,S355J0H,S355J2H,S390,S390J0H,S390J2H,S415,S415J0H,S415J2H,S455,S450J0H,S450J2H

JIS G 3444 Carbon Steel Tubes for General Structural Purpose- STKR 90,400,490,500,540

JIS A5525 Steel Pipe Pile-SPS290,SPS400,SPS490,SP500,SPS500

KS F4602 Steel Pipes Piles

KS F4605 Steel Pipe Sheet Pile

3. Coating Specifications

Fusion Bonded Epoxy – Fusion Bond Epoxy is a powder epoxy thermosetting coating applied for anticorrosion protection to steel pipelines. The pipe is first blast cleaned and heated. Then epoxy powder is spray applied by electrostatic guns to melt and form a uniform layer that hardens within a minute from application. Utilizing industry accepted materials supplied by manufacturers such as 3M, DuPont, and Valspar, the facility can apply FBE in a wide range of thickness to cost effectively meet any project specifications.

Fusion Bonded Epoxy with Abrasion Resistance Overcoating (FBE/ARO) – Utilizing two completely separate powder systems, the facility can produce FBE with an ARO at unprecedented processing speeds using industry accepted materials such as 3M 6352, DuPont 7-2610, and Lilly 2040.

Fusion Bonded Epoxy with High Temperature Resistant Overcoating – Utilizing two completely separate powder systems, the facility can produce FBE with a high operating temperature resistant overcoating such as DuPont’s Nap-Gard Gold and 3M’s 6258.

Fusion Bonded Epoxy with Zap-Wrap Overcoating – The facility is capable of processing line pipe with connections and of applying the Zap-Wrap abrasion resistance overcoating to the ends of each pipe.

ASTM A950: Standard Specification for Fusion-Bonded Epoxy-Coated Structural Steel H-Piles and Sheet Piling.

ASTM A972: Standard Specification for Fusion-Bonded Epoxy-Coated Pipe Piles.

CSA-Z245.20 Standard for External Fusion Bond Epoxy Coating for Steel Pipe

AS 3862 Standard Specification for External Fusion-Bonded Epoxy Coating for Steel Pipes

AWWA C213 Standard for Fusion Bonded Epoxy Coating for the Interior and Exterior of Steel Water Pipelines.

EN 10289 Steel Tubes and Fittings for Onshore and Offshore Pipelines-External Liquid Epoxy and Epoxy-Modified Coating

ISO 21809-2 Petroleum and natural gas industries-External coatings for buried or submerged pipelines used in pipeline transportation systems-Part 2: Fusion-bonded epoxy coatings

ISO 12944 Paints & Varnishes – Corrosion Protection of Steel Structures by protective paint system (parts 1 – 8)

ISO 20340 Paints and varnishes – Performance requirements for protective paint systems for offshore and related structures

ISO 15741: Paints and Varnishes - Friction-Reduction Coatings for the Interior of On-and Offshore Steel Pipelines for Non-Corrosive Gas.

NACE RP0394-2002: Application, Performance, and Quality Control of Plant-Applied, Fusion-Bonded Epoxy External Pipe Coating.

Product Image