Product Description

ASME/ANSI B16.9 - 2001 - Factory-Made Wrought Steel Buttwelding Fittings

ASME/ANSI B16.11 - 2001 - Forged Steel Fittings, Socket-Welding and Threaded

ASME/ANSI B16.21 - 1992 - Nonmetallic Flat Gaskets for Pipe Flanges (c) dimensions and allowable tolerances.

ASME/ANSI B16.25 - 1997 - Buttwelding Ends

ASME/ANSI B16.28 - 1994 - Wrought Steel Buttwelding Short Radius Elbows and Returns

MSS STANDARDS

MSS SP-43: Wrought Stainless Steel Butt Welding Fittings

MSS SP-75: Specification for High Test Wrought Butt Welding Fittings -WPHY 42,WPHY 46,WPHY 52,WPHY 60,WPHY 65,WPHY70,WPHY80

MSS SP-79: Socket Welding Reducer Inserts

JIS STANDARDS

JIS B2311: Steel Butt Welding Pipe Fittings for ordinary use

JIS B2312: Steel Butt Pipe Fittings

JIS B2313: Steel Plate Butt Welding Pipe Fittings

JIS B2316: Steel Socket Welding Pipe Fittings

BS STANDARDS

BS 1640: Steel Butt Welding Pipe Fittings for petroleum Industry-Part 1: Wrought Carbon and ferritie Alloy Steel Fittings

BS 1965: Butt Welding Pipe Fittings for pressure purpose Part 1:Carbon Steel & Austenitic Stainless Steel

ASTM STANDARDS

ASTM A105: Forging Carbon Steel for Piping Component

ASTM A181: Forging Carbon Steel for General Purpose Piping

ASTM A182: Forged or Rolled Alooy Steel Pipe Flanges, Forged Fittings, and Valves and Parts for high temperature Service

ASTM A234: Pipe Fittings of Wrough Carbon Steel and alloy steel for Moderate and elevated Temperatures

ASTM A350: Forgin Carbon AND Low-Alloy Steel, requiring Notch Toughness Testing for pipiping Components

ASTM A403: Wrough Autenitic Stainless Steel Pipe Fittings

ASTM A420: Pipe Fittings of Wrough Carbon Steel and alloy steel for low Temperatures Service

ASTM A815: Wrough Ferritic, Ferritic/Autenitic and martensitic Stainless Steel Pipe Fittings

ASTM 860: Wrough High Strenght, Low Alloy Steel, Butt Welding Fittings

DEP 31.40.21.34-Gen Carbon and low alloy steel pipeline flanges for use in oil and gas operations (amendments/supplements to MSS SP-44)

DEP 31.40.21.30-Gen Pipeline fittings (amendments/supplements to MSS SP-75)

DEP 31.40.21.31-Gen.Pipeline isolating joints (amendments/supplements to MSS SP-75)

ISO 15590-2 Petroleum and natural gas industries - induction bends, fittings and flanges for pipeline transportation systems Part 2: Fittings

IPS-M-PI-150: Standard for Flanges and Fittings

AS 1281 Cement Mortar Lining of Steel Pipes and Fittings

AS 1579 Arc Welded Steel Pipes and Fittings for Water and Waste Water

AS 4087 Metallic Flanges for Waterworks Purposes

AS 4321 Fusion-Bonded Medium Density Polyethylene Coating and Lining for Pipes and Fittings

AS2053-1Conduits and fittings for electrical installations Part 1 General requirement

AS 2053-7 Conduits and fittings for electrical installations - Rigid metal conduits and fittings

AS 3688 water supply - Metallic fittings and end connectors

TOTAL GS EP PLR 222 Carbon steel flanges and branch outlet fittings and forged components for pipelines (sweet service)

TOTAL GS EP PLR 223 Carbon steel tees for pipelines (sweet service

| TEES |

| ASME B31.8/ MSS SP 75 WPHY 65 /ASME B16.9 |

| NB |

OD |

Cener To end |

|

|

| Mm |

In |

D1×D2 |

C |

M |

| 20×20 |

3/4×3/4 |

25×2526.7×26.7 |

29 |

29 |

| 20×15 |

3/4×1/2 |

25×2026.7×21.3 |

29 |

29 |

| 25×25 |

1×1 |

32×3233.4×33.4 |

38 |

38 |

| 25×20 |

1×3/4 |

32×2533.4×26.7 |

38 |

38 |

| 32×32 |

1.1/4×1.1/4 |

38×3842.2×42.2 |

48 |

48 |

| 32×25 |

1.1/4×1 |

38×3242.2×33.4 |

48 |

48 |

| 40×40 |

1.1/2×1.1/2 |

45×4548.3×48.3 |

57 |

57 |

| 40×25 |

1.1/2×1 |

45×3248.3×33.4 |

57 |

57 |

| 50×50 |

2×2 |

57×5760.3×60.3 |

64 |

64 |

| 50×25 |

2×1 |

57×3260.3×33.4 |

64 |

51 |

| 65×65 |

2.1/2×2.1/2 |

76×7673×73 |

76 |

76 |

| 65×40 |

2.1/2×1.1/2 |

76×4570.3×48.3 |

76 |

67 |

| 80×80 |

3×3 |

89×89 |

86 |

86 |

| 80×50 |

3×2 |

89×5788.9×60.3 |

86 |

76 |

| 100×100 |

4×4 |

108×108114.3×114.3 |

105 |

105 |

| 100×50 |

4×2 |

108×57114.3×60.3 |

105 |

89 |

| 125×125 |

5×5 |

133×113141.3×141.3 |

124 |

124 |

| 125×80 |

5×3 |

133×89141.3×88.9 |

124 |

111 |

| 150×150 |

6×6 |

159×159168.3×168.3 |

143 |

143 |

| 150×100 |

6×4 |

159×108168.3×114.3 |

143 |

130 |

| 200×200 |

8×8 |

219×219 |

178 |

178 |

| 200×100 |

8×4 |

219×108219.1×114.3 |

178 |

156 |

| 250×250 |

10×10 |

273×273 |

216 |

216 |

| 250×125 |

10×5 |

273×133273.1×141.3 |

216 |

191 |

| 300×300 |

12×12 |

325×325323.9×323.9 |

254 |

254 |

| 300×200 |

12×8 |

325×219323.9×219.1 |

254 |

229 |

| 350×350 |

14×14 |

377×377355.6×355.6 |

279 |

279 |

| 350×200 |

14×8 |

377×219355.6×219.1 |

279 |

248 |

| 400×400 |

16×16 |

426×426406.4×406.4 |

305 |

305 |

| 400×250 |

16×10 |

426×273406.4×273.1 |

305 |

283 |

| 450×450 |

18×18 |

478×478457×457 |

343 |

343 |

| 350×250 |

18×10 |

478×273457×273.1 |

343 |

308 |

| 500×500 |

20×20 |

529×529508×508 |

381 |

381 |

| 500×300 |

20×12 |

529×325508×323.9 |

381 |

346 |

| 550×550 |

22×22 |

559×559 |

419 |

419 |

| 550×400 |

22×16 |

559×406.4 |

419 |

381 |

| 600×600 |

24×24 |

630×630610×610 |

432 |

432 |

| 600×400 |

24×16 |

630×426610×406.4 |

432 |

406 |

| 650×650 |

26×26 |

660×660 |

495 |

495 |

| 700×700 |

28×28 |

720×720711×711 |

521 |

521 |

| 700×400 |

28×16 |

720×426711×406.4 |

521 |

457 |

| 750×750 |

30×30 |

762×762 |

559 |

559 |

| 750×500 |

30×20 |

762×508 |

559 |

508 |

| 800×800 |

32×32 |

820×820813×813 |

597 |

597 |

| 800×500 |

32×20 |

820×529813×508 |

597 |

533 |

| 850×850 |

34×34 |

846×846 |

635 |

635 |

| 850×600 |

34×24 |

846×610 |

635 |

584 |

| 900×900 |

36×36 |

920×920914×914 |

673 |

673 |

| 900×500 |

36×20 |

920×529914×508 |

673 |

584 |

| 950×950 |

38×38 |

965×965 |

711 |

711 |

| 950×600 |

38×24 |

965×610 |

711 |

635 |

| 1000×1000 |

40×40 |

1020×10201016×1016 |

749 |

749 |

| 1100×700 |

44×28 |

1020×7201118×711 |

813 |

698 |

| 1150×1150 |

46×46 |

1168×1168 |

851 |

800 |

| 1150×800 |

46×32 |

1168×813 |

851 |

749 |

| 200×1200 |

48×48 |

1220×12201219×1219 |

889 |

838 |

| 1200×650 |

48×26 |

1219×660 |

889 |

762

|

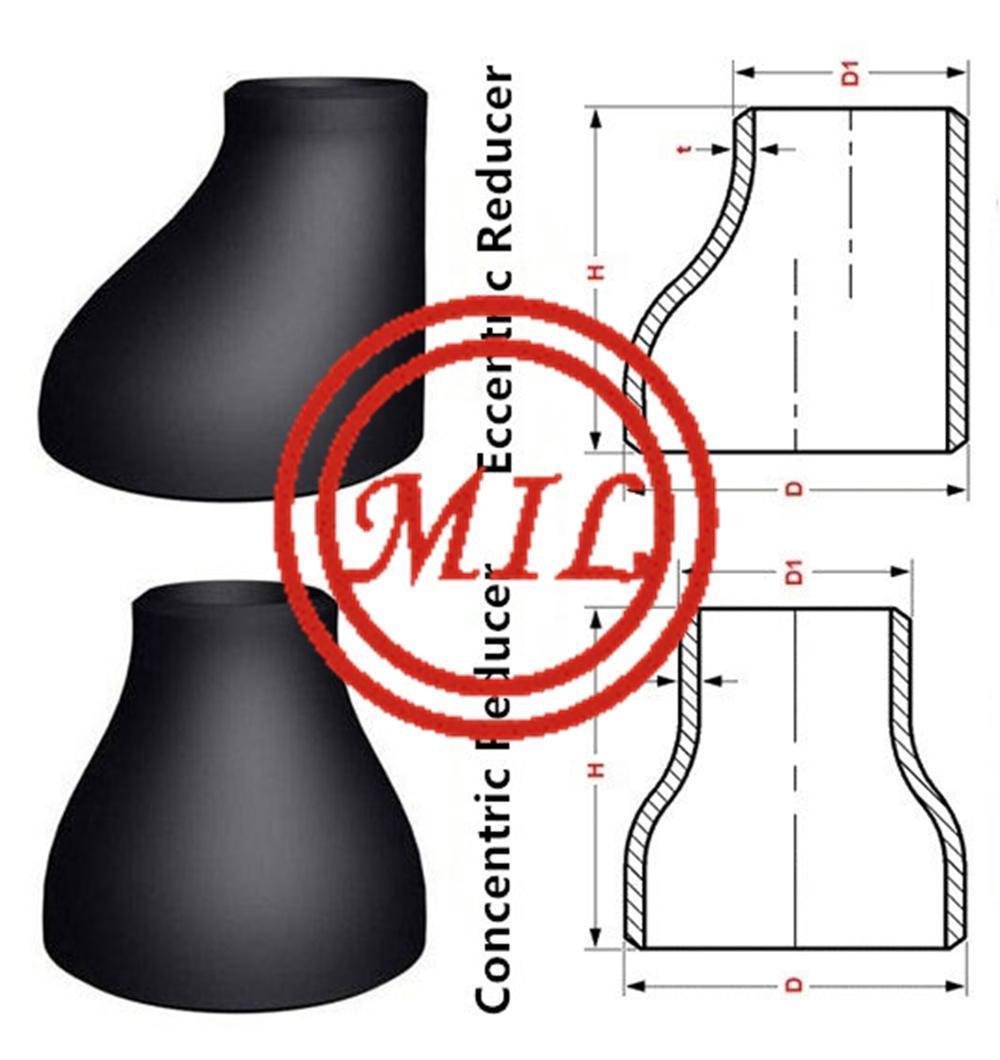

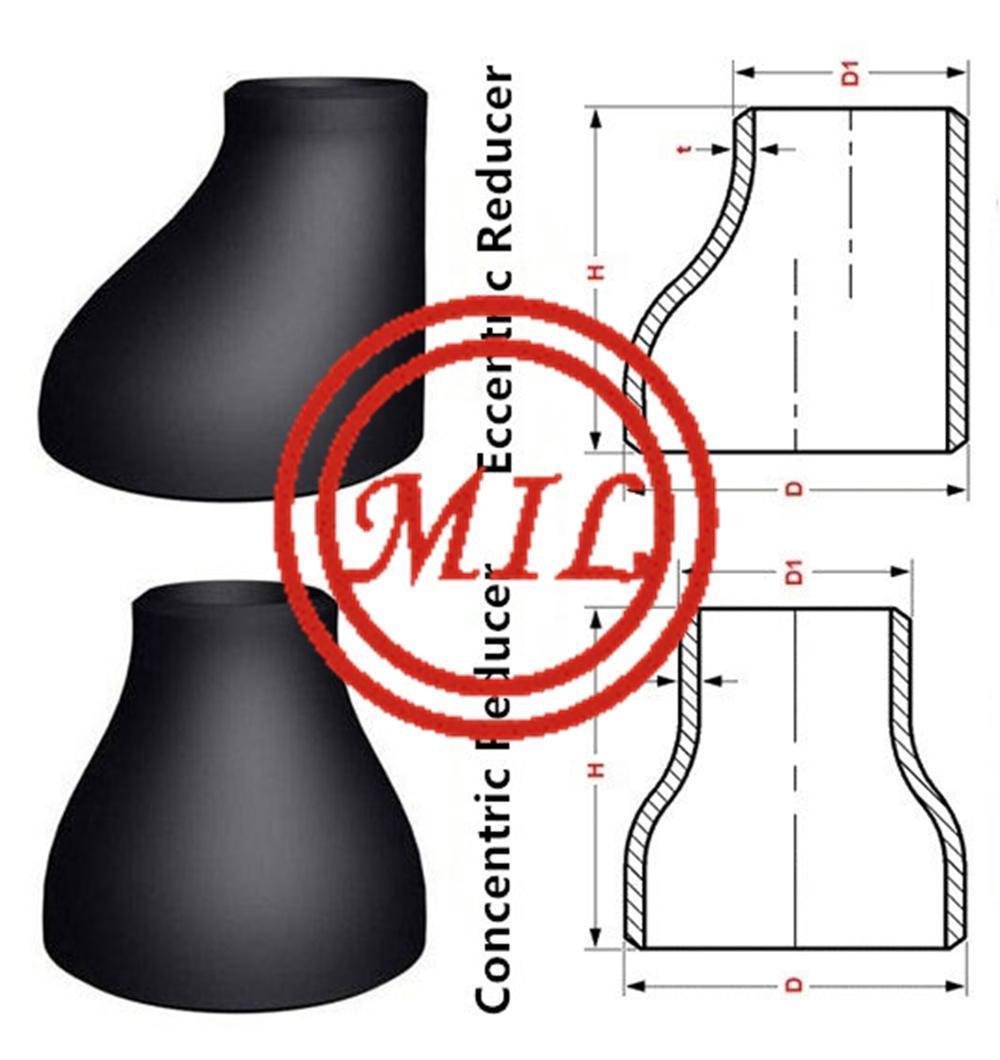

Product Image