Product Description

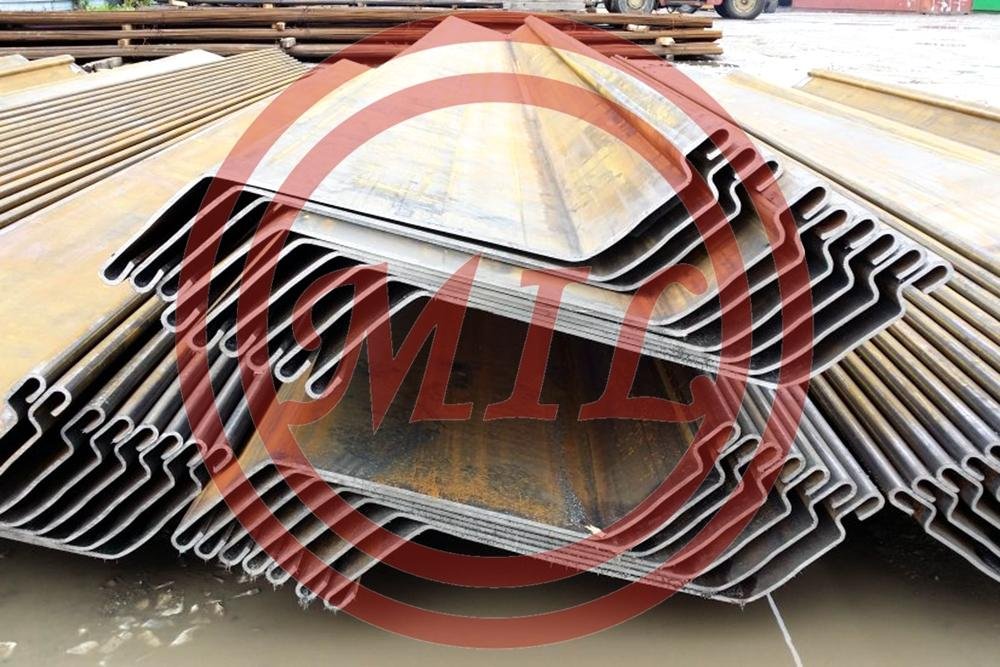

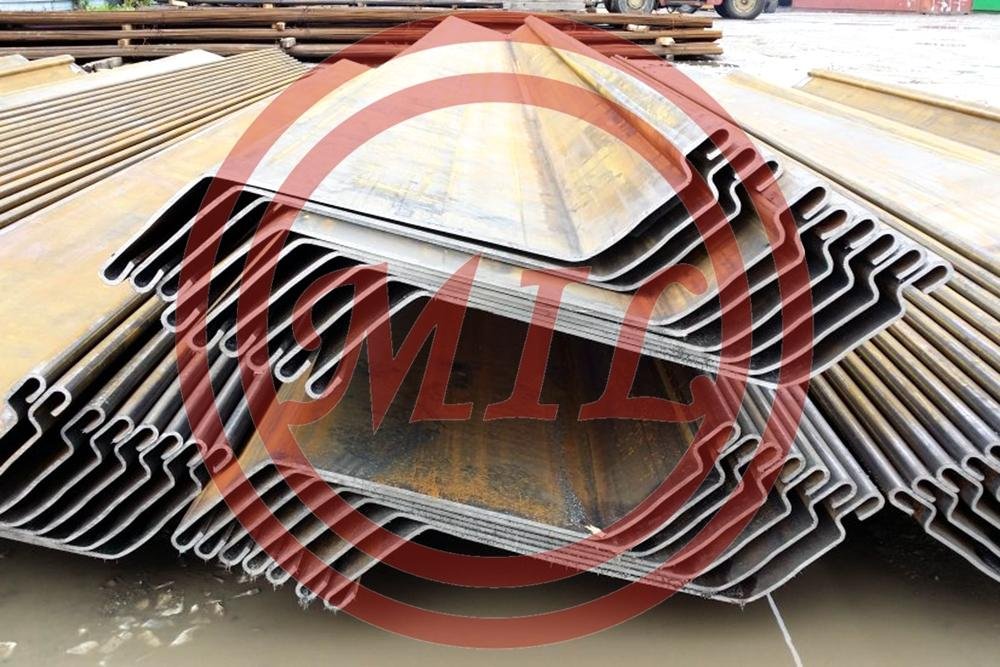

Steel Pipe Sheet Piles

Steel pipe sheet piles, which consist of steel pipes with joints welded onto them, are widely used as retaining walls and as riverside and harbor revetments. Steel pipe sheet piles can be used to make a circular, oval or rectangular shaped well foundation which combines the functions of foundation piles and a cofferdam, realizing efficient and economical design and construction processes. Having large cross-section properties, steel pipe sheet piles can realize compact foundation designs that minimize interference with river flows.

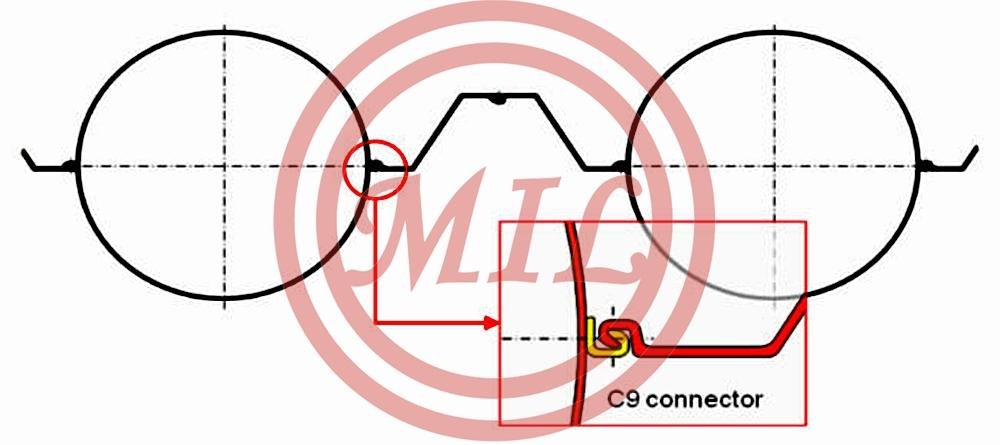

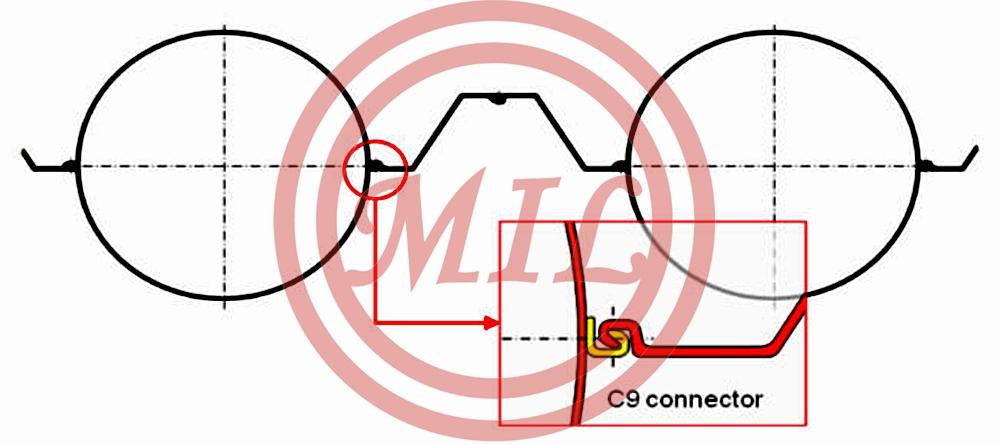

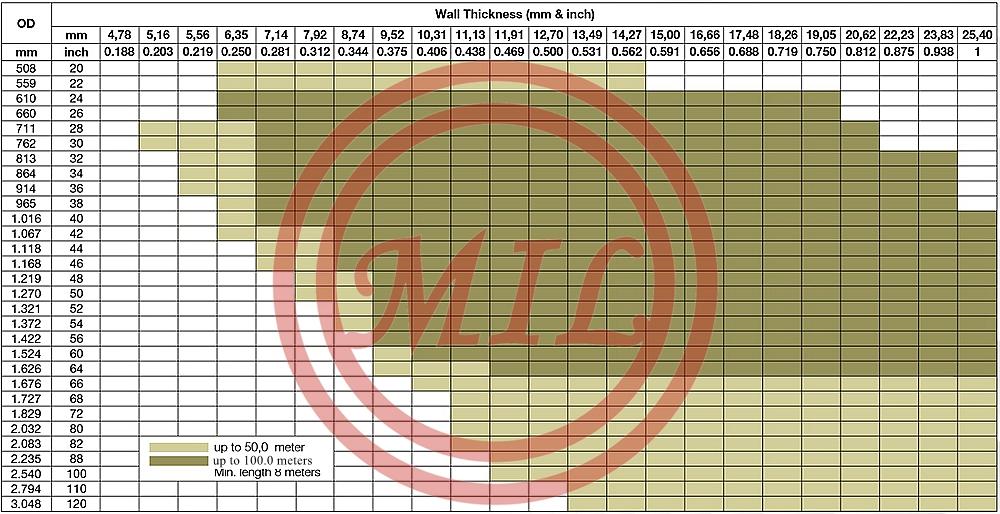

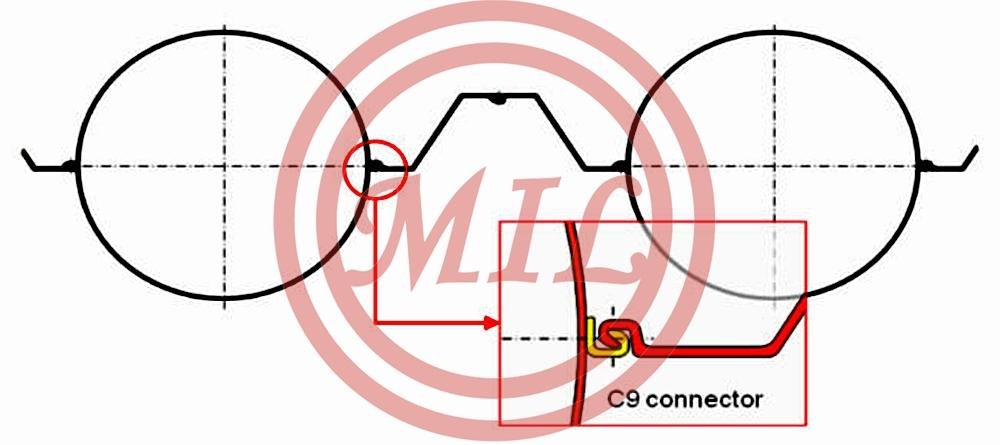

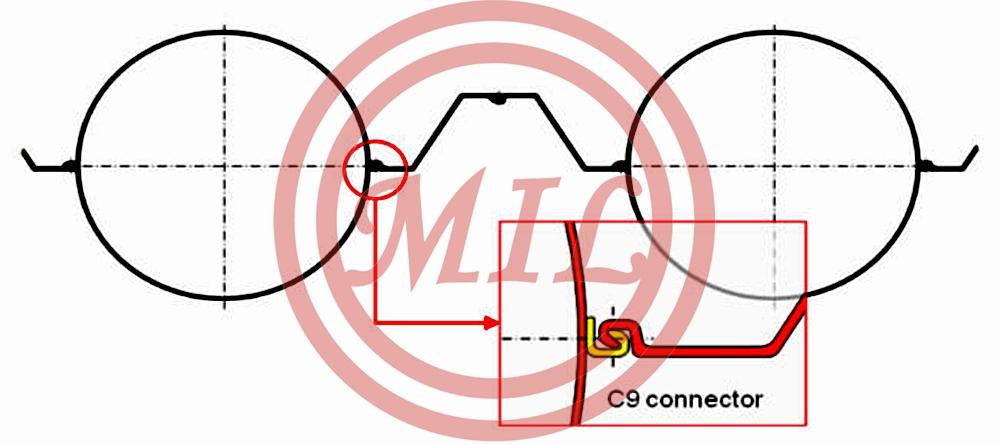

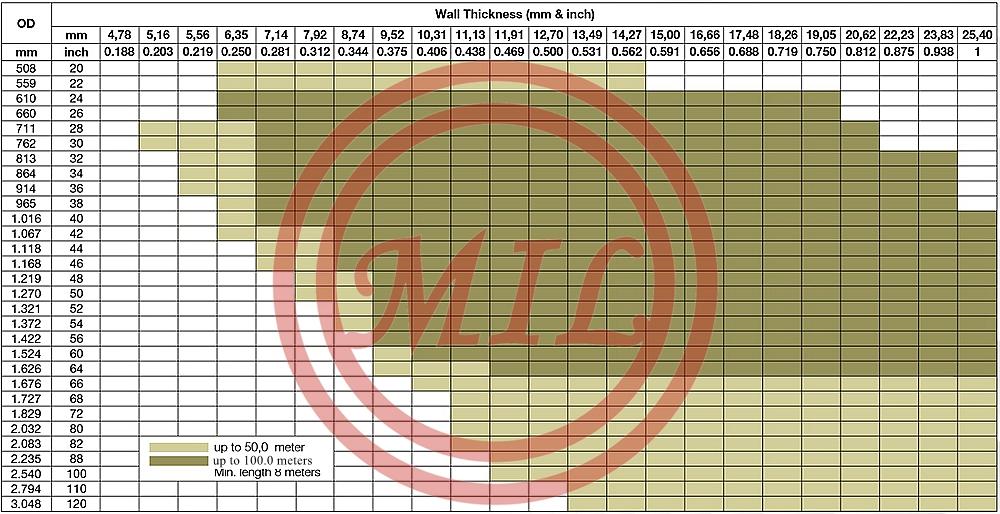

For quay-wall construction of ports, in tunnels or river crossings combi-walls are used as retaining walls. The system consists of tubular piles (King Piles) equipped with connectors (named also interlocks, locking bars or clutches) compatible with U or Z type infill sheet piles. Sheet piles that transfer the pressure of the main loads to the King piles are connected with E21 / C6 or E22 / C9 interlocks welded on both sides. Spiral pipes present the advantage of long lengths without circular welds and resistance against buckling. Other combi-walls (pipe to pipe systems) with different connectors can also be supplied. Coating of the splash zone with a paint system might be more economical than steel wall increase for corriosion allowance. The stability of the wall against operational loads (port cranes, stacked container loads…) can be ensured with the use of tye rods attaching the quay wall to an anchor wall made of shorter tubulars or double sheet piles

Combi-wall A Combi-wall is a combination of large-diameter steel pipe piles and sheet piles installed to form a retaining wall structure. Pipe piles provide resistance to overturning forces and the steel sheet piles serve as in-fill between the pipes. Combi-walls can be left in place permanently or elements can be extracted and re-used when no longer needed.

The pipe pile portion of a Combi-wall is typically installed as a bored pile which may or may not be backfilled with concrete and reinforcing steel, depending on the application. Sheet piles are installed in the spaces between the pipes with a vibratory hammer and are aligned with pipes using welded interlocking points. Other pile cross-sections such as H-piles can also be combined with sheet piles to form a Combi-wall.

Advantages

Combi-walls provide a cost-effective shoring alternative to the secant wall while providing significantly more load bearing capacity than a sheet pile wall.

Combi-walls are effective in temporary applications as the steel elements can be easily removed and re-used once the structure is no longer needed.

Joint Shape Varieties for Different Applications

Steel pipe sheet pile joints are available in three types: P-P, L-T and P-T. You can choose joint designs to suit your applications, whether for revetment structures, bridge foundations, cofferdam walls or retaining walls. The P-P type, in particular, can deliver superior cut-off performance through use of a waterstop treatment.

Steel pipe piles and steel pipe sheet piles are widely used in ports/harbors (piers, seawalls, and breakwaters), urban civil engineering (earth-retaining walls and cofferdams), bridges (foundations for steel pipe sheet pile foundations), and other applications, along with widening their applications due to enlargement of the structures sizes, growth of water depth for the structures and increase in construction work at sites where the bearing strata are deep under thick soft ground.

Product Image