Product Description

Reference Specifications:

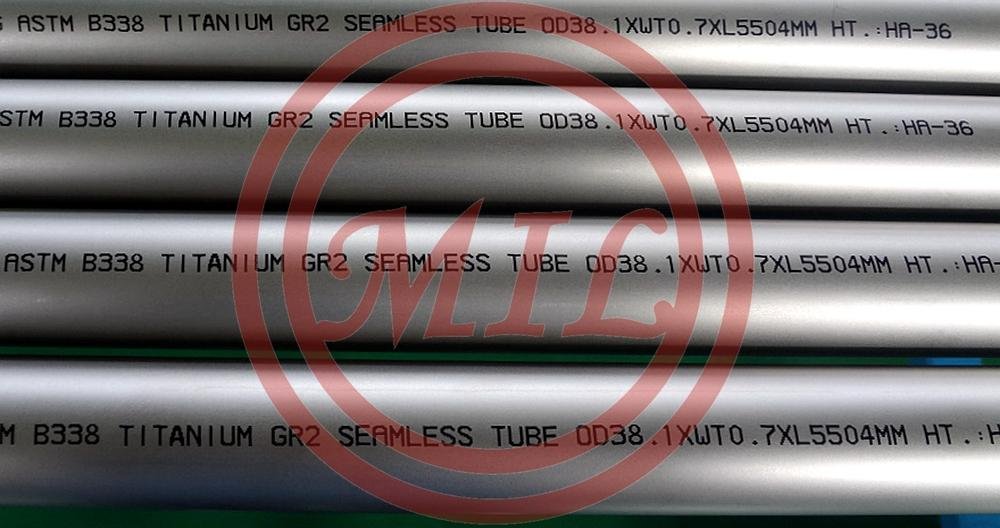

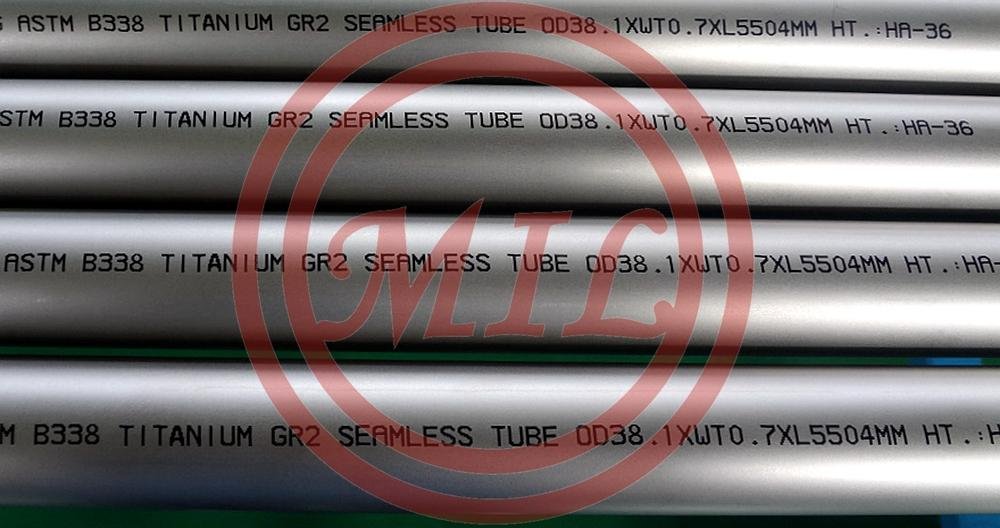

ASTM B338/ASME SB338 Seamless and Welded Titanium &Titanium Alloy Tubes for Condensers & Heat Exchangers

ASTM B363/ASME SB363 Seamless and Welded Unalloyed Titanium & Titanium Alloy Welding Fittings

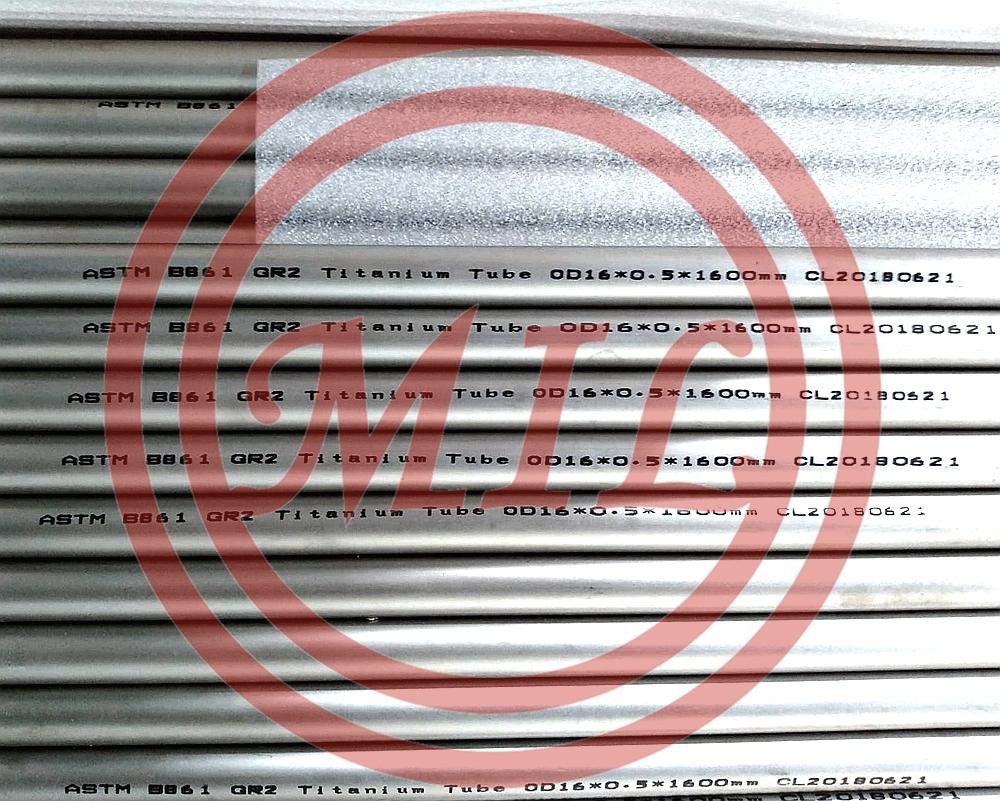

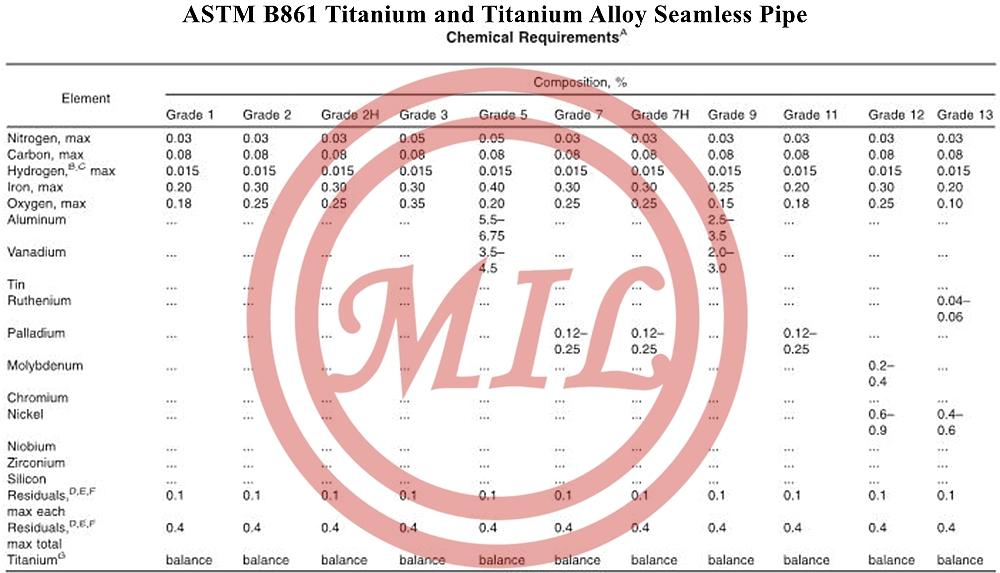

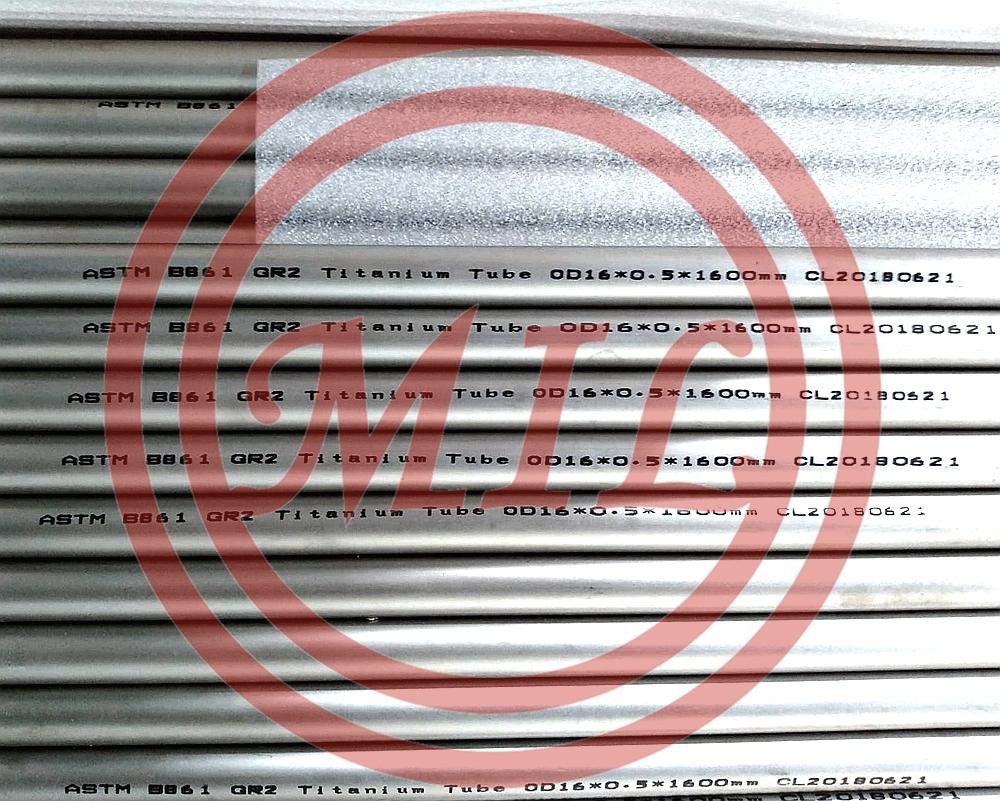

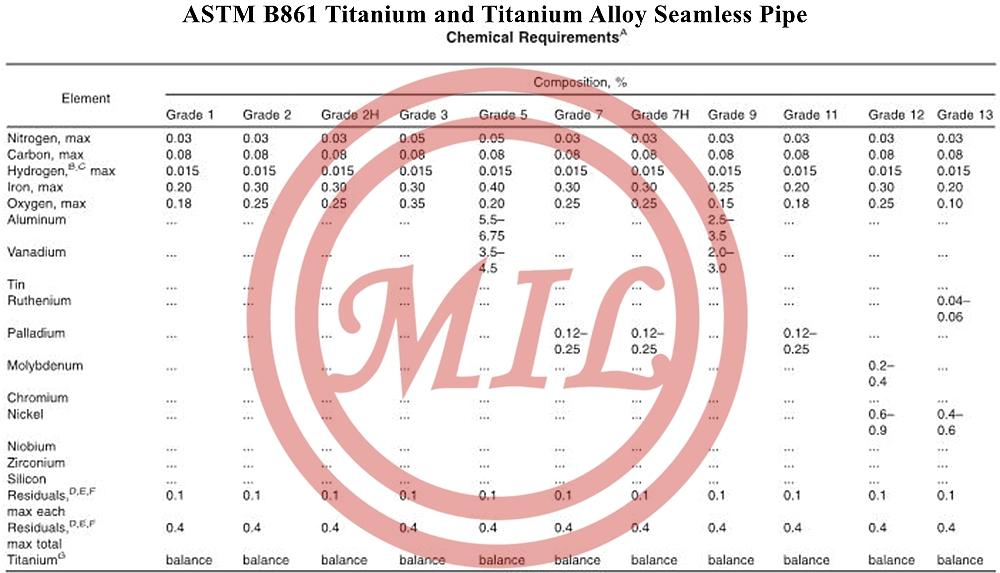

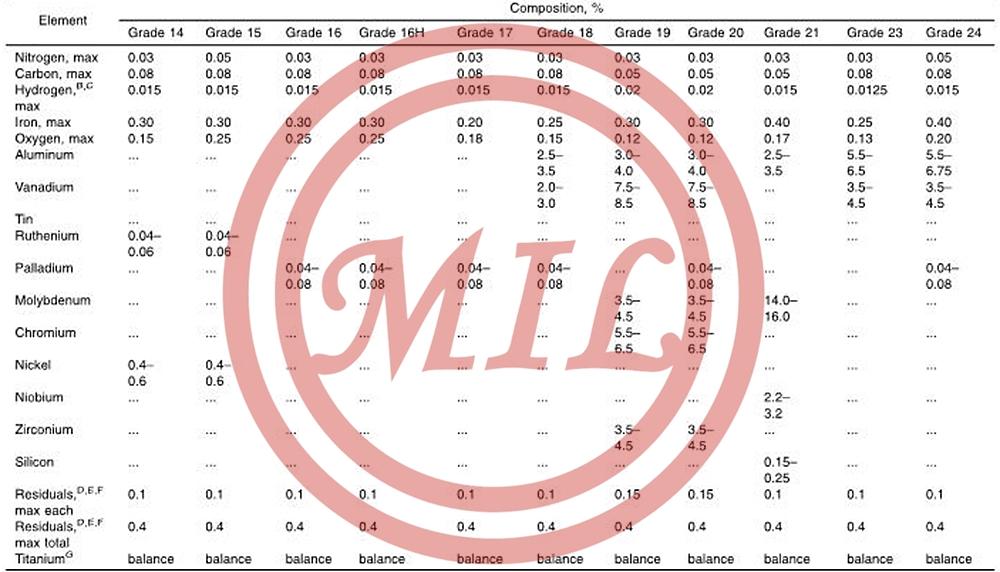

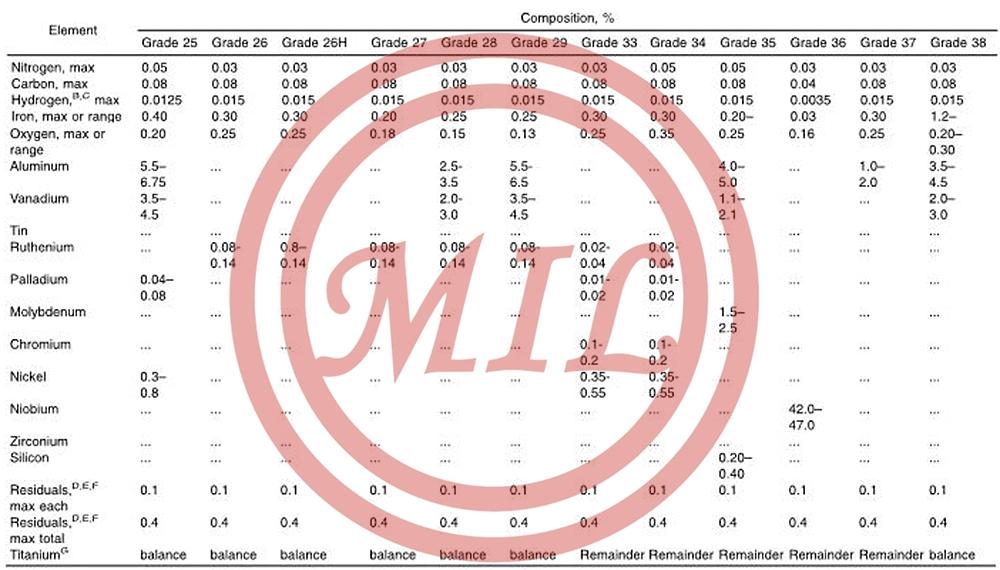

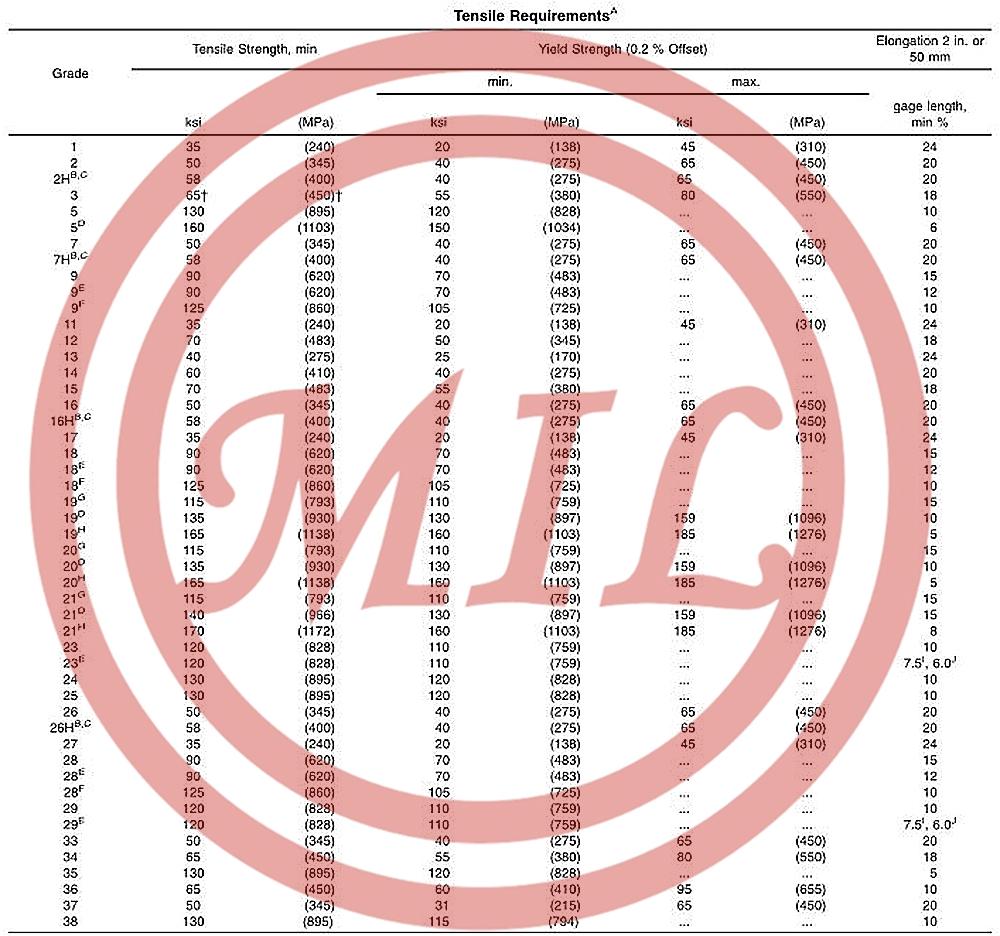

ASTM B861/ASME SB861 Titanium and Titanium Alloy Seamless Pipe

ASTM B862/ASME SB862 Titanium and Titanium Alloy Welded Pipe

AMS 4922 Seamless Hydraulic Tubing - Cold Worked and Precipitation Heat Treated---Titanium Alloy - 15V-3.0CR-3.0AL-3.0SN

AMS 4941 Tubing, Welded, Annealed, 40,000 psi (275 MPa) Yield Strength

AMS 4942 Tubing, Seamless, Annealed, 40,000 psi (275 MPa) Yield Strength

AMS 4943 Hydraulic, Seamless Tubing 3.0AL-2.5V Annealed

AMS 4944 Seamless, Hydraulic Tubing 3.0AL-2.5V Cold Worked, Stress Relieved

AMS 4945 Tubing, Seamless, Hydraulic, 3AL-2.5V, Texture Controlled, 105 ksi (724 Mpa)Yield Strength Cold Worked, Stress Relieved

DIN 17861 Seamless Circular Titanium And Titanium Alloy Tubes

DIN 17866 Welded Circular Titanium And Titanium Alloy Tubes

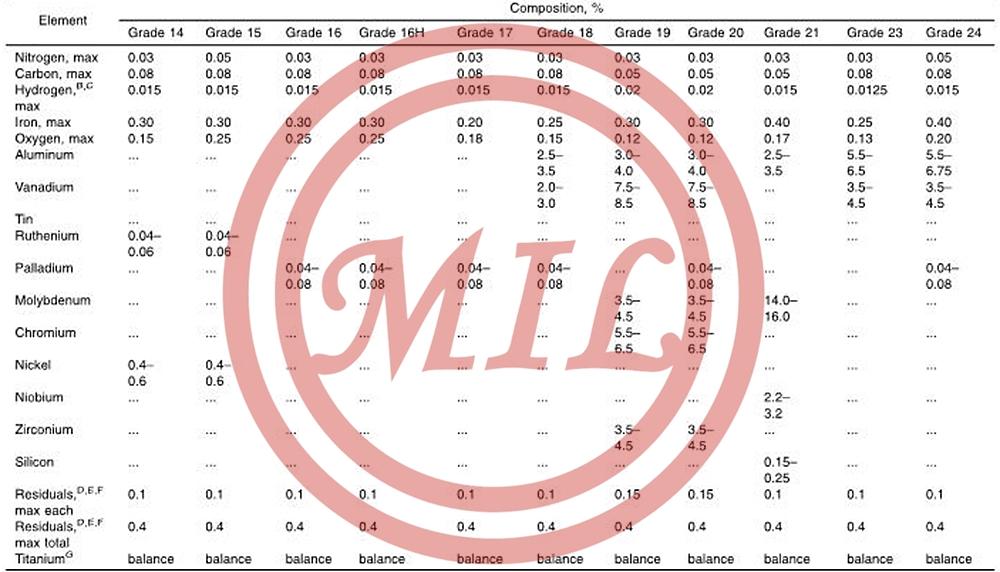

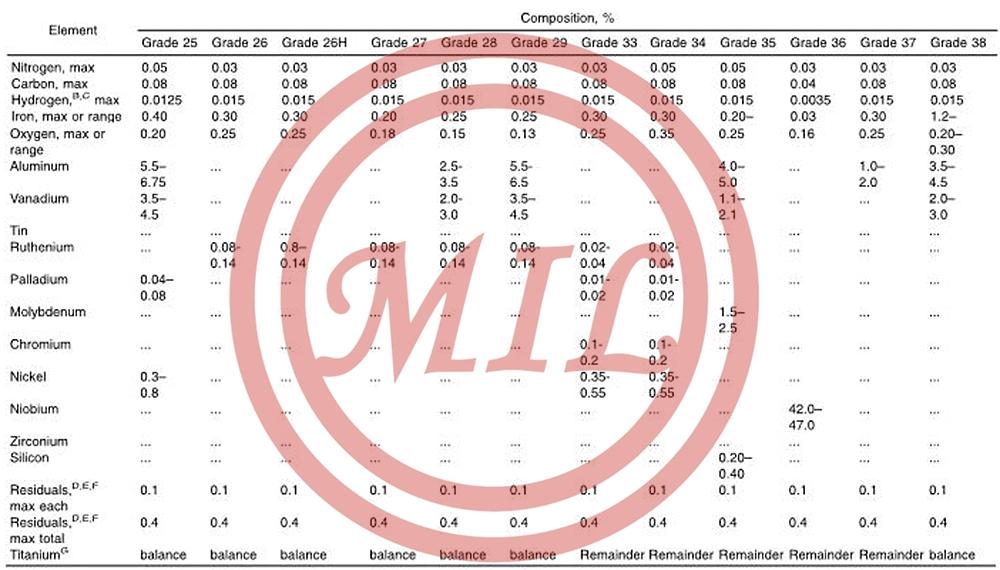

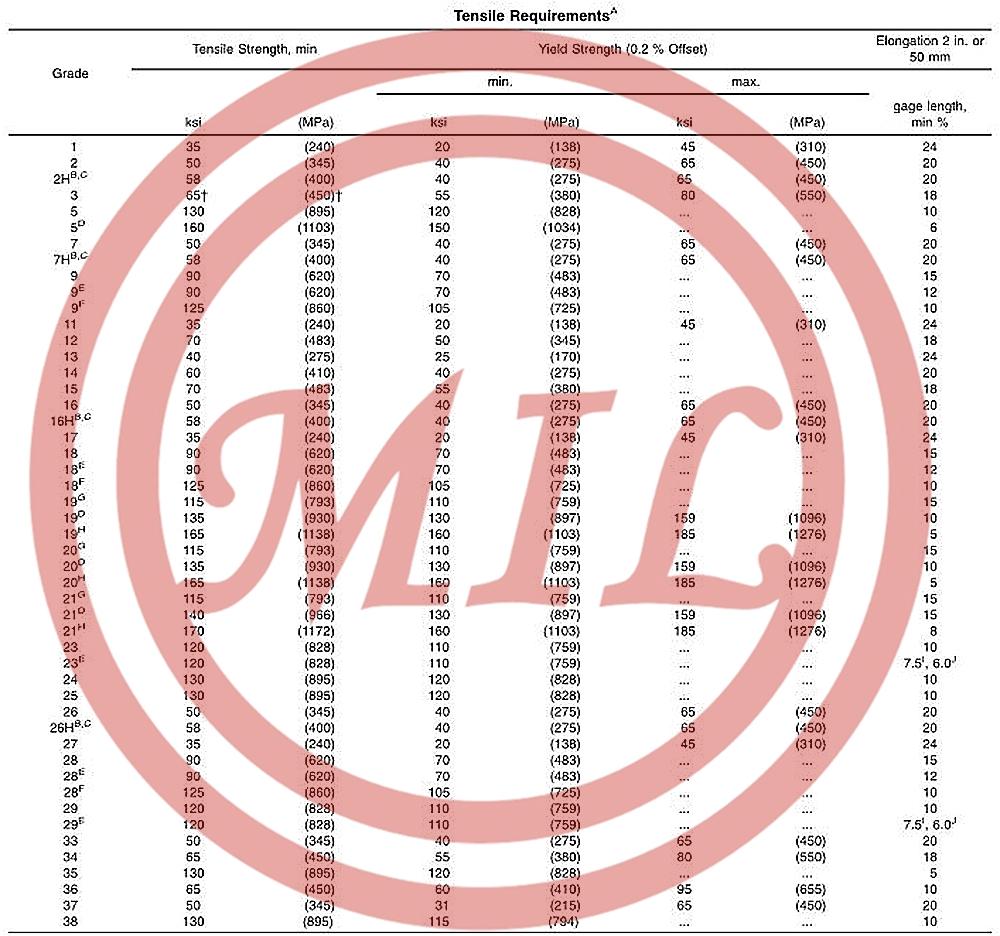

Grades Available

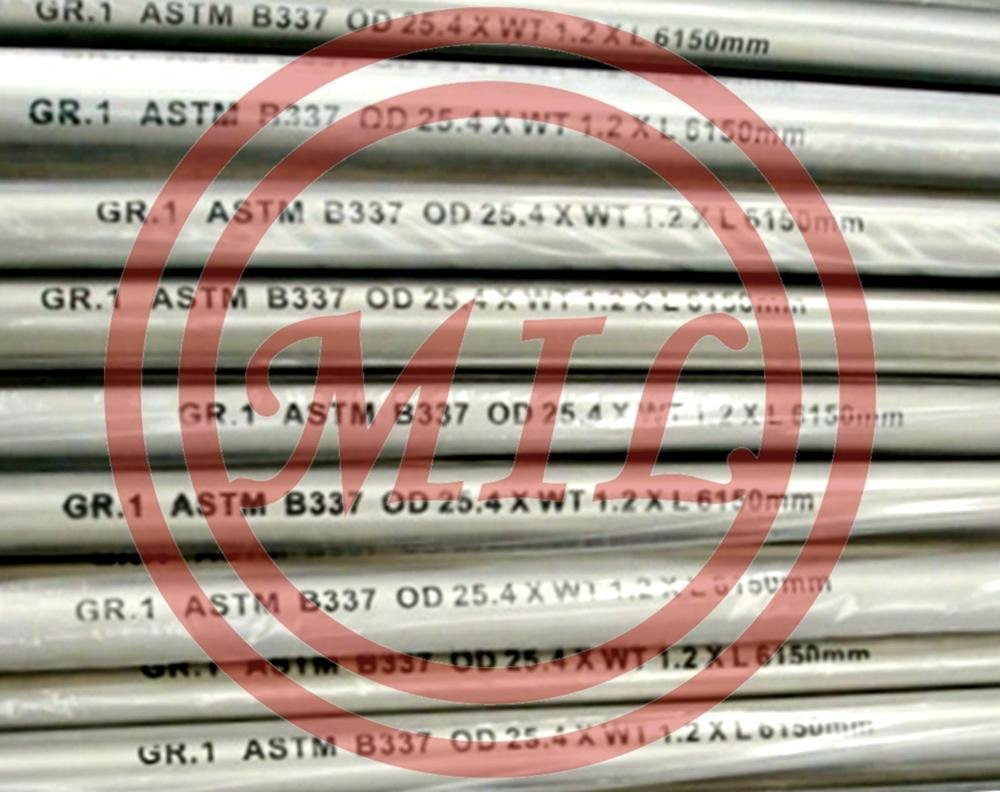

- Gr1 R50250titanium tube, CP titanium, low oxygen

- Gr2 R50400titanium tubing, CP titanium, standard oxygen

- Gr7 R52400titanium pipe, Ti-Pd, standard oxygen

- Gr9 R56320titanium piping, Ti-3Al-2.5V

- Gr11 R52250titanium alloy tube, Ti-Pd, low oxygen

- Gr12 R53400titanium alloy tube, Ti-Mo-Ni

- Gr16 R52402titanium alloy pipe, Ti-Pd, standard oxygen

- Gr17 R52252titanium alloy pipe, Ti-Pd, low oxygen

Features of Titanium Grades:

- Titanium Grade 1

- This is a non-alloyed, low strength titanium product containing low oxygen with high formability. This grade is used in airframes, heat exchangers and desalination units.

- Titanium Grade 2

- This is a non-alloyed, medium strength titanium product. This grade is used in airframes, aircraft engines, and marine equipment. This grade features good weldability and corrosion resistance.

- Titanium Grade 3

- This is a non-alloyed, high strength titanium product providing excellent corrosion resistance and good weldability. This grade is primarily used in airframes and aircraft engine parts.

- Titanium Grade 4

- This is the highest strength pure non-alloyed titanium product. This grade is used exclusively for aircraft components, marine equipment, surgical implants, and hydraulic tubing. It contains good formability and it is corrosion resistant.

- Titanium Grade 5 (6Al – 4V)

- This is an alloyed products containing 6% aluminum and 4% vanadium.

- Titanium Grade 7

- This is a non-alloyed medium strength product containing palladium in the range of 0.12% to 0.25%. It has superior corrosion resistance. This grade is mainly used for industrial applications.

- Titanium Grade 9 (3Al – 2.5V)

- This is an alloyed titanium product containing 3% aluminum and 2.5% vanadium.

- 6AL - 2Sn - 4Zr - 2Mo (6-2-4-2)

- This is an alloyed product containing 6% aluminum, 2% tin, 4% zirconium, and 2% molybdenum.

- 6AL - 6V - 2Sn (6-6-2)

- This is an alloyed product containing 6% aluminum, 6% vanadium, and 2% tin.

- 5AL - 2.5Sn (5-2.5)

- This is an alloyed product containing 5% aluminum and 2.5% tin.

- 8AL-1V-1Mo (8-1-1)

- This is an alloyed product containing 8% aluminum, 1% vanadium, and 1% molybdenum.

Applications:

Oil and gas industry

Chloride environments such as seawater handling and process systems and hydraulic and process fluid tubes in umbilicals.

Seawater cooling

Tubing for heat exchangers and coolers on oil platforms, in refineries, chemical industries, process industries and other industries using seawater or chlorinated seawater as coolant.

Refineries and petrochemical plants

Tubes and pipes where the process environment contains a high amount of chlorides or sulfides.

Geothermal wells

Heat exchangers in geothermal exploitation units, systems exposed to geothermal or high-salinity brines, tubing and casing for production.

Pulp and paper industry

Tubing for chloride containing bleaching environments.

Desalination plants

Tube and pipe for seawater transport, heat exchanger tubing, and pressure vessels for reverse osmosis units.

Mechanical components requiring high strength

Propeller shafts and other products subjected to high mechanical load in seawater and other chloride-containing environments. Excellent mechanical and corrosion resistance properties make titanium tubing and pipe an economical choice for many other applications by reducing the product life cycle costs of equipment.

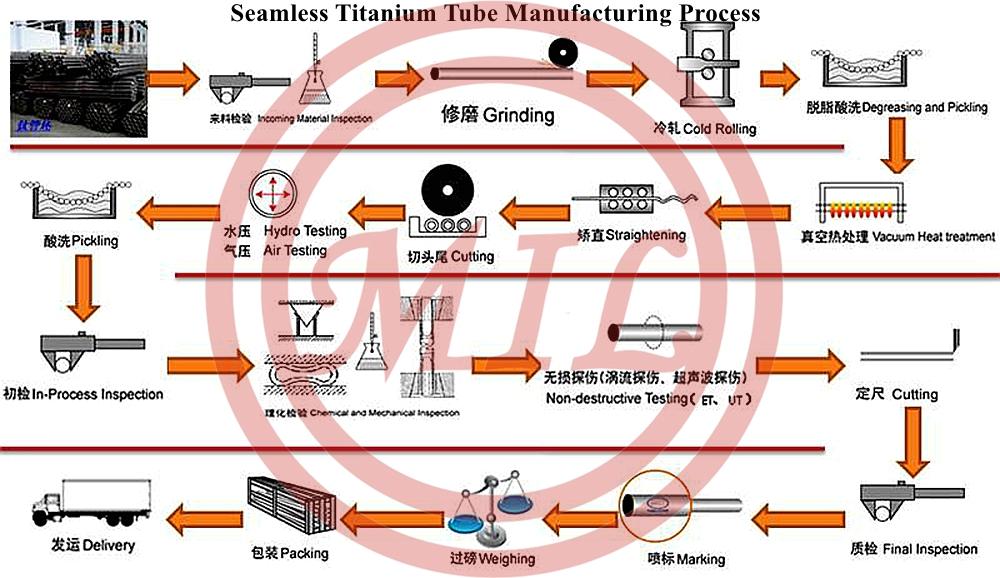

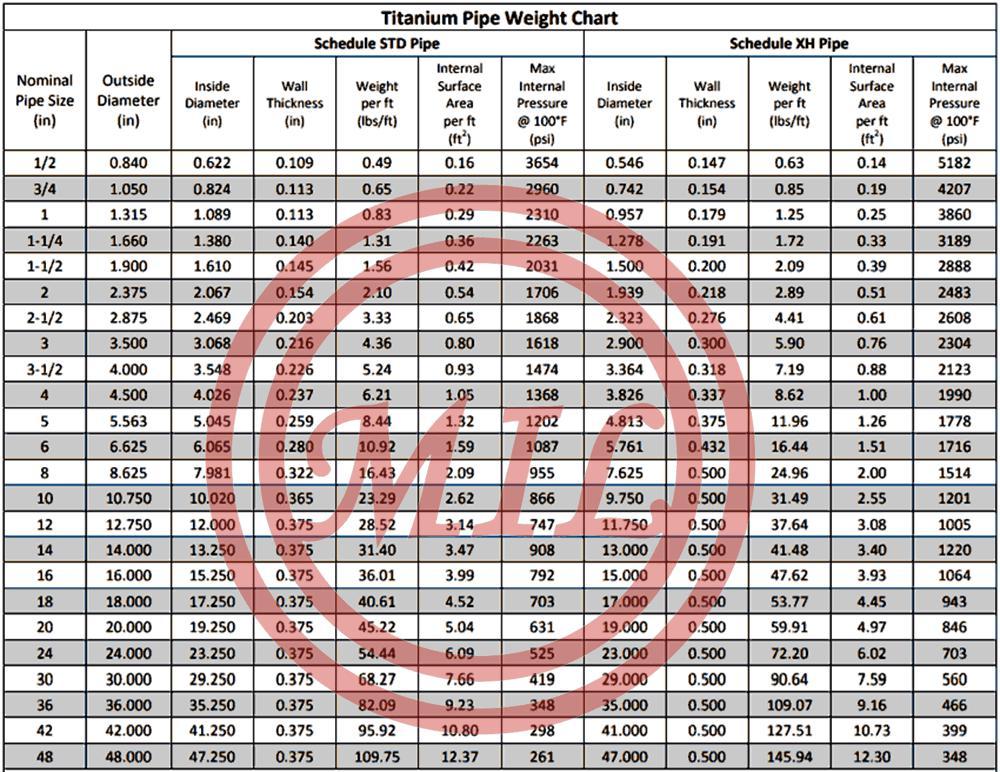

Product Image