Product Description

Glass Reinforced Polyester/Epoxy Pipes (GRP/GRE)

GRP Pipes or Glass Reinforced Plastics pipes are composite material pipes consisting of a polymer matrix that is reinforced with glass fibers. They have very high corrosion resistance ability and thus used widely for low-temperature corrosion-resistant applications. In many places, the term FRP is used interchangeably for GRP pipes.

GRP Family

• GRP: Glass – fibre reinforced plastic.

• GRE: Glass – fibre reinforced epoxy.

• GRV: Glass – fibre vinyl ester.

• GRUP: Glass – fibre reinforced unsaturated polyester.

The different types of pipes are selected according to the required properties like chemical resistance, temperature resistance, and mechanical properties.

Physical Properties

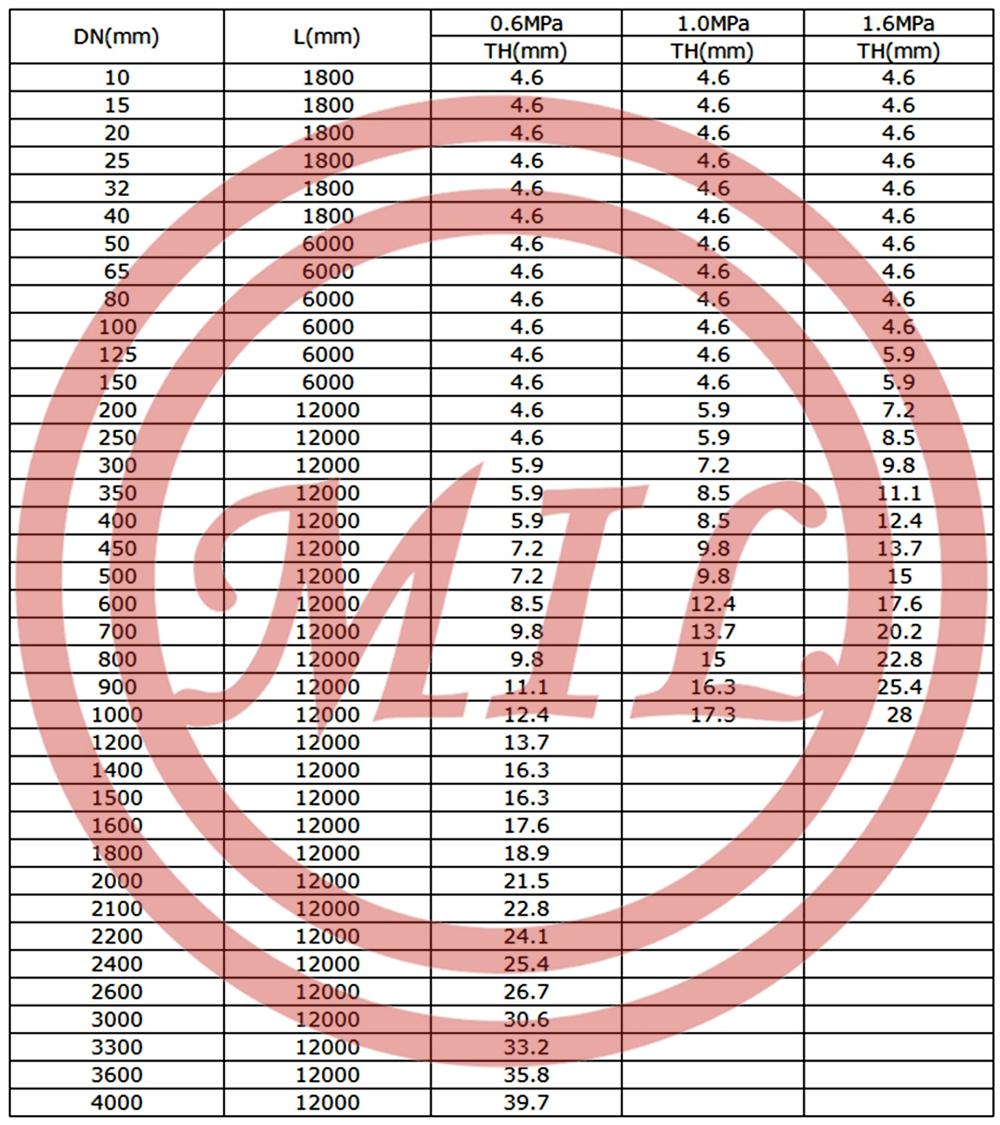

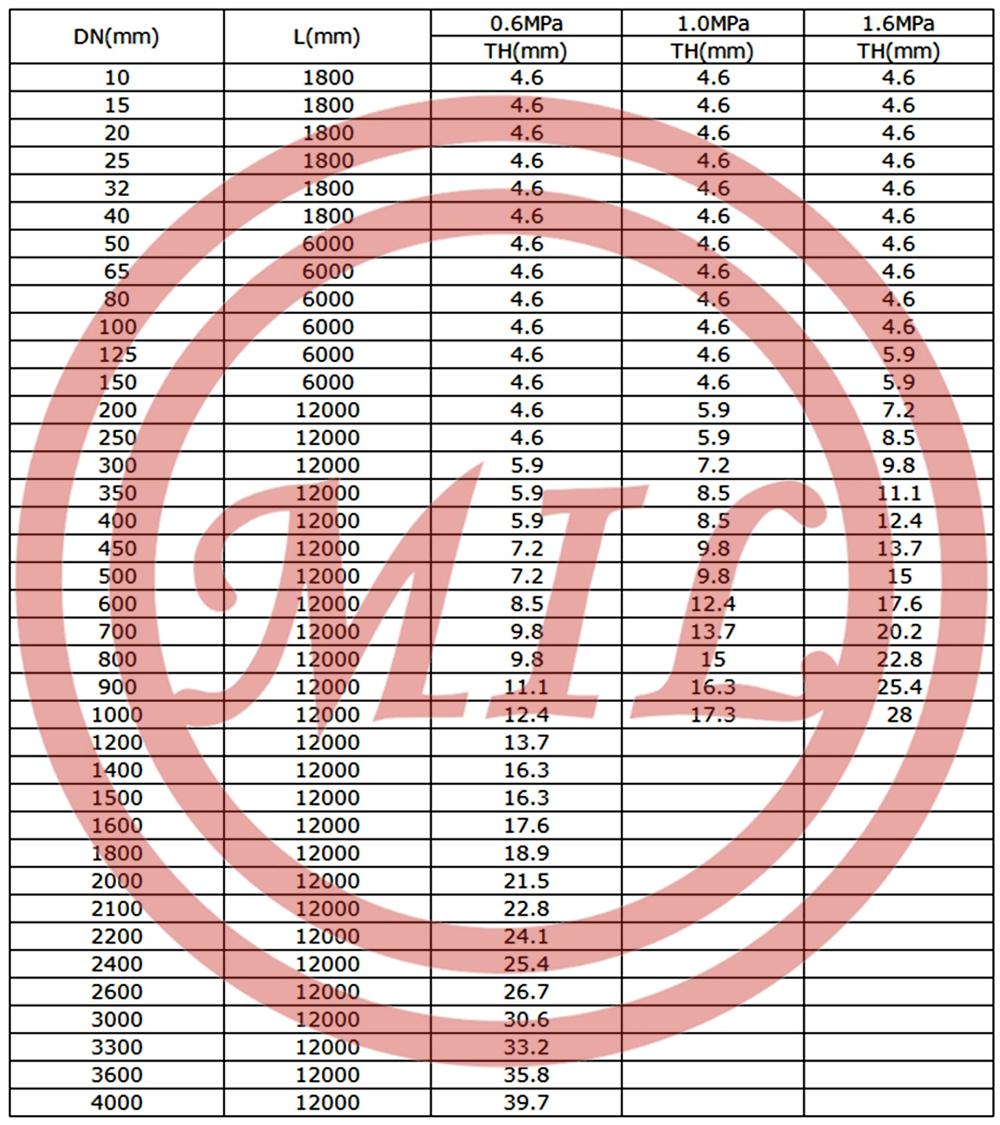

Nominal Diameter [DN] 10 - 4000 mm

Nominal Pressure [PN] up to 32 bar

Nominal Stiffness [SN] up to 20000 N/m²

Types of Manufacturing of GRP Pipes

• Filament winding.

• Centrifuge

• Continuous winding or Drostholm Method.

• Helical Filament winding

GRP PipeJoining methods

• Adhesive Joint

• Flange Joint

• Lamination Joint

• Rubber Seal Lock Joint

Characteristics of GRP Pipe

• Corrosion resistance: Corrosion resistant to both inside and outside corrosion. As a result, additional linings and exterior coatings are not required.

• When the ratio of strength per unit of weight is considered, fibreglass composites surpass CS and SS.

• Lightweight: Fibreglass piping is only one-sixth the weight of steel products and 10% the weight of similar concrete products.

• Electrical properties: Standard fibreglass pipes are nonconductive. Some manufacturers offer conductive fibreglass piping system for transporting fluids like Jet Fuel.

• Dimensional stability: Fibreglass material meets the most stringent material stiffness, dimensional tolerance, weight and cost criteria.

• Low maintenance cost: Fibreglass piping is easy to maintain because it does not rust, is easily cleaned and requires minimal protection from the environment.

Advantages of GRP Pipes

• Long life; highly durable.

• Low maintenance cost.

• High Corrosion resistance.

• Low lifecycle cost.

• No need for cathodic protection.

• Less transportation and handling cost.

• Environmental friendly.

• Wide application range.

• Economic when compared with DSS pipe (Duplex stainless steel)

|

Reference Standards:

- AWWA C950 Glass Fibre Reinforced Thermosetting Resin Pressure

- ASTM D2996 Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

- ASTM D2310 Machine-Made "Fibreglass" (Glass-Fibre-Reinforced Thermosetting-Resin) Pipe

- ASTM-D3262 “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Sewer Pipe

- ASTM D3517 ‘Fibreglass” (Glass-Fibre-Reinforced Thermosetting -Resin) Pipe

- ASTM D3754 “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin Sewer and Industrial Pressure Pipe

- ASTM D4161 “Fibreglass” (Glass-Fibre-Reinforced Thermosetting - Resin) Pipe Joints Using FlexibleElastomeric Seals

- ASTM D4024 Machine Made “Fiberglass” (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

- ASTM D5685 “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pressure Pipe Fittings

- BS 5480 Glass Reinforced Plastics (GRP) Pipes, Joints and Fittings for Use for Water Supply or Sewerage

- CSA Z662 Oil & gas pipeline systems

- DIN 16868 Glass fibre reinforced unsaturated polyester resin (UP-GF) pipes

- DIN 16869 Centrifugally cast filled glass fibre reinforced unsaturated polyester resin (UP-GF) pipes;

- EN 705 Plastics piping systems - Glass-reinforced thermosetting plastics (GRP) pipes and fittings - Methods for regression analyses and their use;

- EN 1115 Plastics piping systems for underground drainage and sewerage under pressure - Glass-reinforced thermosetting plastics (GRP) based on unsaturated polyester resin (UP);

- EN 1796 Plastics piping systems for water supply with or without pressure – Glassfiber reinforced thermosetting plastics (GRP) based on unsaturated polyester resin (UP)

- EN 14364 Plastics piping systems for drainage and sewerage with or without pressure – Glassfiber reinforced thermosetting plastics (GRP) based on unsaturated polyester resin (UP) – Specifications for pipes, fittings and joints

- ISO 10467 Plastics piping systems for pressure and non-pressure drainage and sewerage – Glassfiber reinforced plastics (GRP) systems based on unsaturated polyester (UP) resin

- ISO 10639 Plastics piping systems for pressure and non-pressure water supply-Glass reinforced thermosetting plastics (GRP) systems based on unsaturated polyester (UP) resin

- ISO 14692 Petroleum and natural gas industries-Glass-reinforced plastics (GRP) piping

- ISO 25780 Plastics piping systems for pressure and non-pressure water supply, irrigation, drainage or sewerage – Glass-reinforced thermosetting plastics (GRP) systems based on unsaturated polyester (UP) resin – Pipes with flexible joints intended to be installed using jacking techniques

|

| |

|

| |

Product Image