|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASTM A536 FM & UL Ductile Iron Grooved Fitting & Grooved Coupling

|

|

| Model No.︰ | - |

| Brand Name︰ | - |

| Country of Origin︰ | - |

| Unit Price︰ | - |

| Minimum Order︰ | - |

|

|

|

|

|

|

|

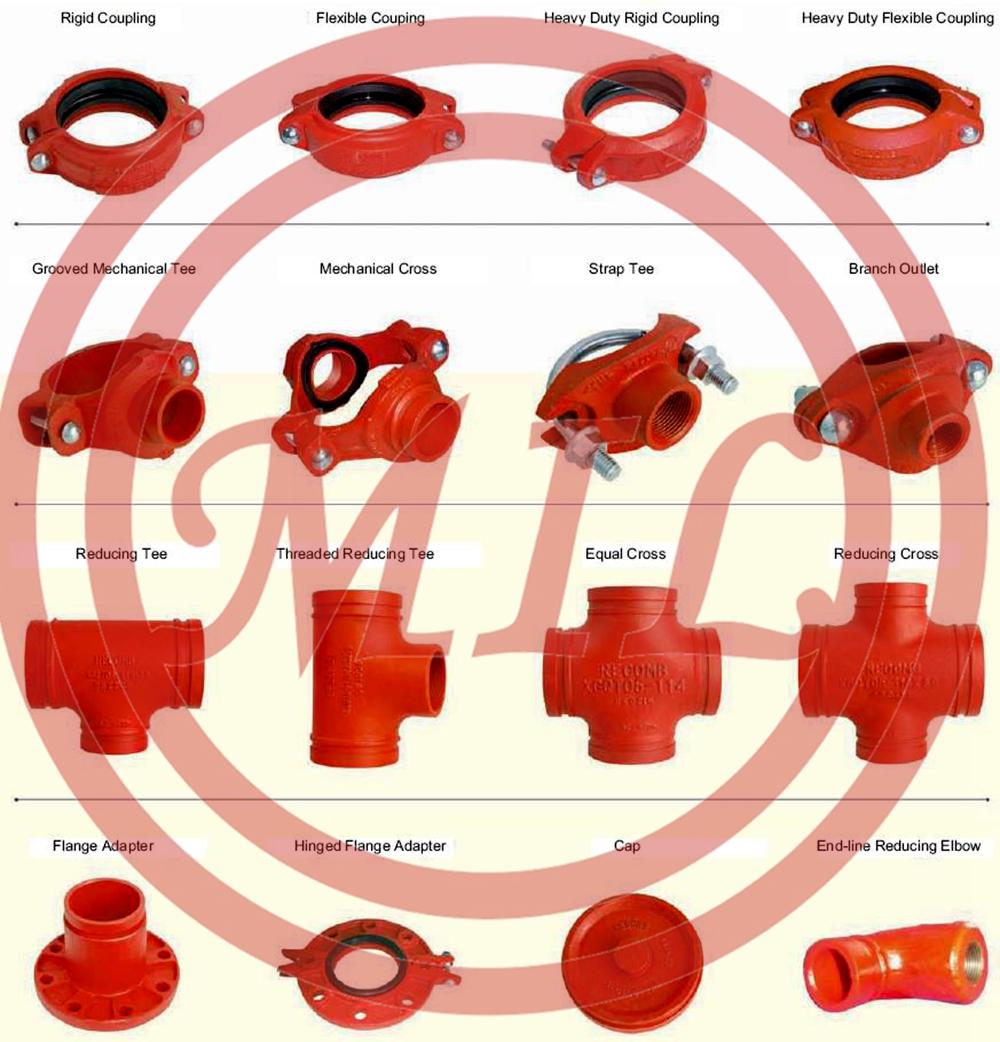

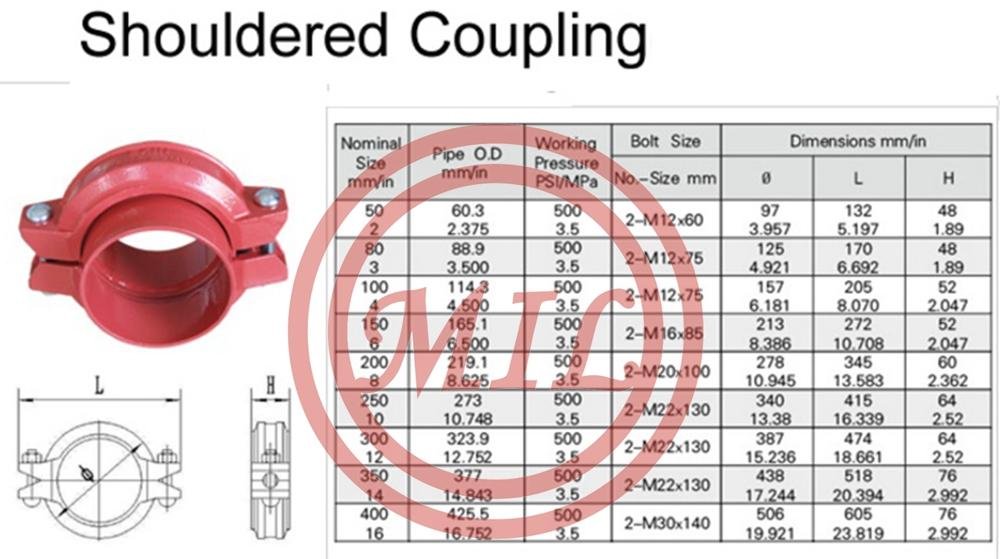

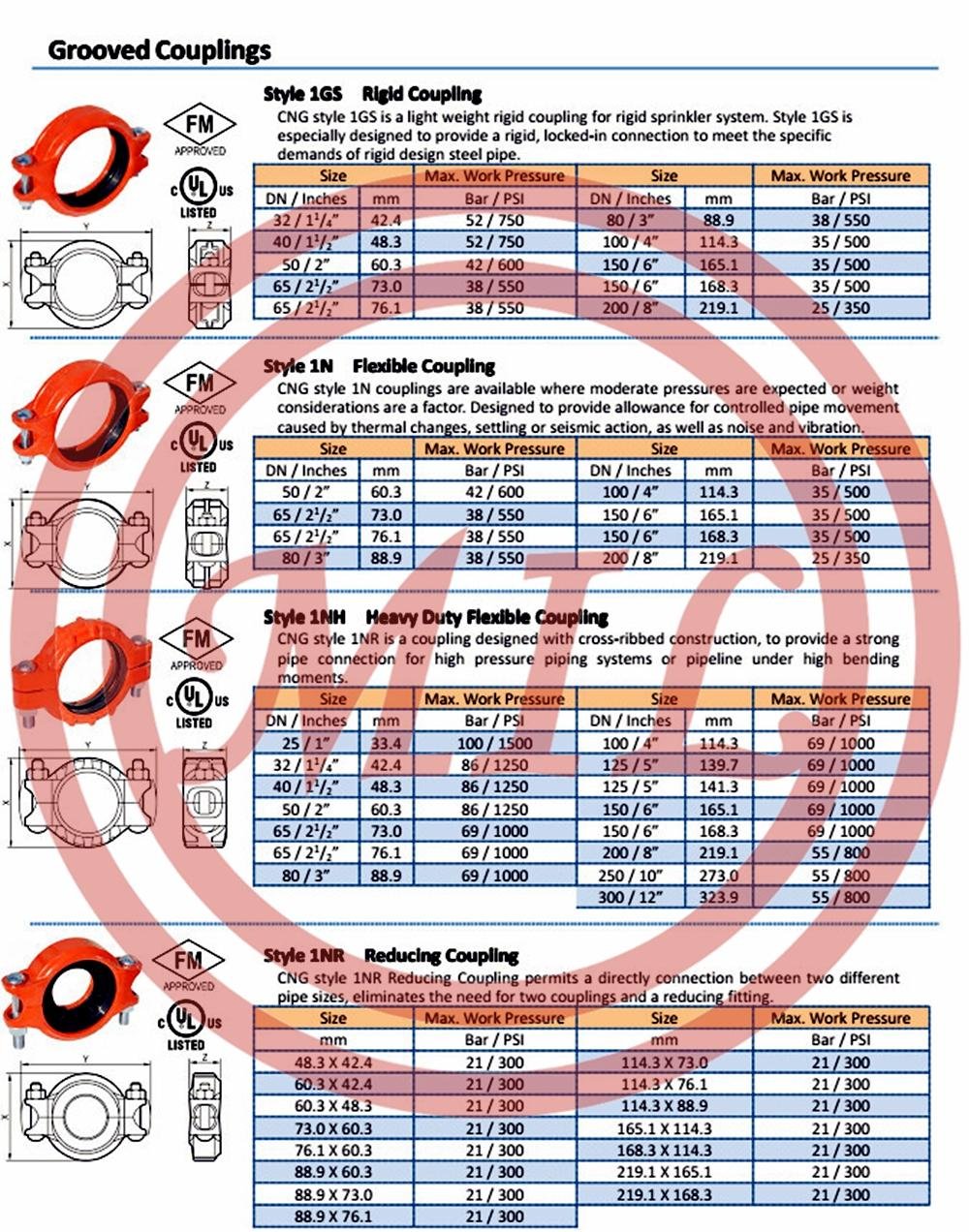

| Specifications︰ | 1)Grooved Fittings series,

2)Coupling, Elbow, Tee, Cross, Cap, --- Pressure: 300PSI, 500PSI

Color: Red RAL3000, Orange color, Galvanized.

Finish: Paint,Epoxy Powder and Darcrome

3)Materail: ASTM A536 65-45-12 QT450-12,

4)Grooved Fitting SGS

Ductile Iron Grooved Fittings With ASTM A536 standard, Including Coupling, Adaptor, Bend, Reducer, Coupling, Elbow, Tee, Cross, Cap, Mechanical Tee, Mechanical Cross caps

We have machines are used for making groove and hole on pipe.

Size: from 1inch to 24inch

EN 10242 Threaded pipe fittings in malleable cast iron;

|

| Standard Met︰ | Grooved Ductile Iron Pipe

Grooved Ductile Iron Pipe is manufactured for air, water, sewage, oil and other liquids where owners, specifiers, and contractors express a preference in lieu of flanged fabrication. The joint employs shoulders or grooves fabricated to the pipe to be used in conjunction with a segmented mechanical coupling. The joint may be designed to be fabricated as rigid or flexible to meet installation requirements. For added flexibility, pipe may be ordered with one end grooved and the other furnished with a wide range of end connections to accommodate particular design requirements.

STANDARDS & CERTIFICATION

Grooved Ductile Iron Pipe is manufactured in accordance with ANSI/AWWA C606; NAPF 400. Ductile iron pipe barrels conform to the requirements of ANSI/AWWA C151/A21.51; NAPF 100 (minimum Class 53, subject to manufacturing tolerances and additional wall thickness for larger diameters, as may be required). Radius grooves may be fabricated to rigid or flexible dimensions as referenced in ANSI/AWWA C606; NAPF 400. Unless specified otherwise pipe is furnished to rigid groove specifications.

WORKING PRESSURE

Grooved ductile iron pipe is manufactured from pipe pro-duced in accordance with ANSI/AWWA C151/A21.51; NAPF 100. Suitable class thickness pipe is rated at the pipe foundry according to the tables contained therein. Since grooved pipe working pressures depend upon the diameter of pipe, grooving details and other methods of adaptation, the coupling manufacturer should be consulted to deter-mine working pressure ratings of the joint. Section 5.2 ANSI/AWWA C606 specifies testing requirements for working pressure ratings. ANSI/AWWA C606 - NAPF 400

LENGTH

Maximum length of grooved pipe is 19’6" or more, depend-ing on size. Exact length (subject to manufacturing toler-ances) may be furnished down to minimum practical lengths depending on size.

INTERIOR LININGS

Unless otherwise specified, grooved pipe is furnished ce-ment-mortar interior lined and seal coated in accordance with ANSI/AWWA C104/A21.4; NAPF 500. Unlined, bitumi-nous lined or other special linings may be available upon request and may be applied in accordance with NAPF 500. Standard cement-mortar and some other linings are individu-ally certified in conformity to ANSI/NSF 61. (See Coatings & Linings).

EXTERIORLININGS

Unless otherwise specified, flanged pipe is furnished with a Standard bituminous exterior coating per ANSI/AWWA C151/A21.51 Section 51.8.1. Standard exterior primers and other special coatings may be available upon request and may be applied in accordance with NAPF 500. (See Coatings & Linings).

NOTE:

Grooved pipe is furnished to rigid groove dimensions unless otherwise specified. Grooved Ductile Iron Pipe is made to order and is not returnable.

|

|

|

Product Image

|

|

Fm Ul Ce Approved Ductile Iron Grooved Pipe Fitting

Galvanized Cast Iron Pipe Fitting Grooved Fittings

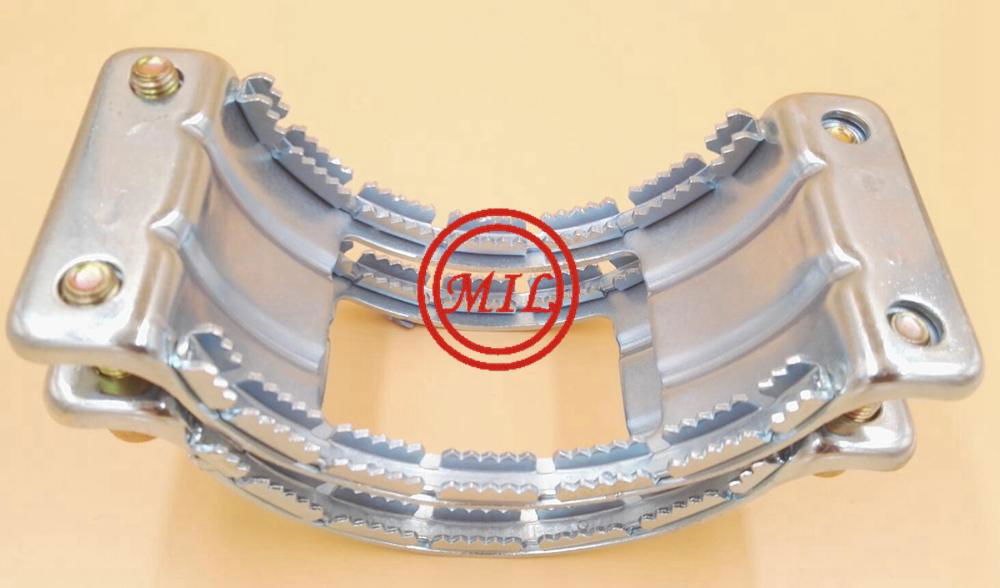

RAPID COUPLING CLAMP

|

|

|

|

|

|

Related Products

|

|

|

|

|

|

|

|

|