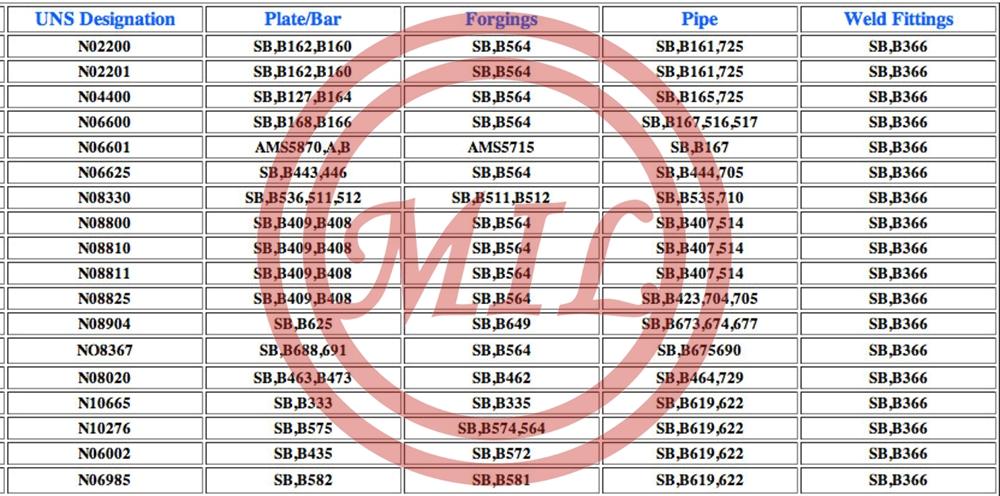

Reference Standards:

ASME SB163 Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

ASME SB165 Nickel-Copper Alloy (UNS N04400)* Seamless Pipe and Tube

ASME SB167 Nickel-Chromium-Iron Alloys, Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617),and Nickel-Iron-Chromium-Tungsten Alloy (UNS N06674) Seamless Pipe and Tube

ASME SB407 Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

ASME SB423 Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825, N08221, and N06845) Seamless Pipe and Tube

ASME SB444 Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 and UNS N06852) and Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219) Pipe and Tube

ASME SB622 Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube

ASTM B673 UNS N08904 UNS N08925 and UNS N08926 Welded Pipe

ASTM B674 UNS N08904 UNS N08925 and UNS N08926 Welded Pipe

ASTM B677 UNS N08904 UNS N08925 and UNS N08926 Seamless Pipe and Tube

ASME SB690 Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and UNS N08367) Seamless Pipe and Tube

ASME SB729 Standard Specification for seamless UNS N08020, UNS N08026, and UNS N08024 nickel alloy pipe and Tube

Description of Nickel & Nickel Alloys

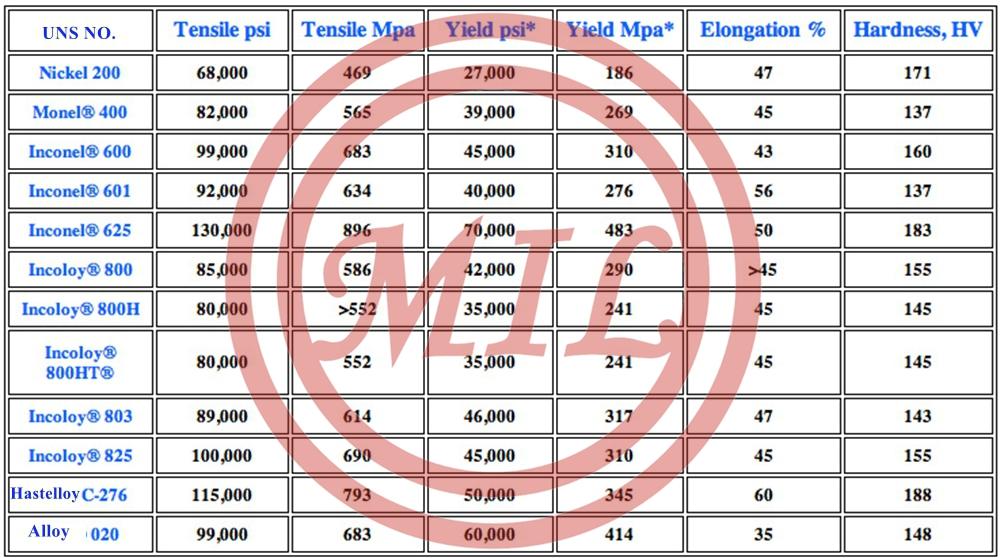

Alloy 20 – Alloy 20 stainless steel is a super-austenitic stainless alloy developed for maximum corrosion resistance to sulfuric acid and other aggressive environments not suitable for typical austenitic grades. Alloy 20 seems to fall in-between both the stainless and nickel categories, as it does contain characteristics of both; however, the unified numbering system (UNS) does ultimately recognize it as a nickel based alloy, hence the UNS N08020 number. Alloy 20 is an austenitic nickel-iron-chromium based alloy with additions of copper and molybdenum. Its nickel content aids in its chloride ion stress and corrosion resistance. The addition of copper and molybdenum provides resistance to hostile environments, pitting and crevice corrosion. Chromium adds to its resistance of oxidizing environments, such as nitric acid, and columbium (or niobium) reduces the effects of carbide precipitation.

Nickel 200 – Nickel 200 alloy is a commercially pure nickel that exhibits good corrosion resistance. It is ferromagnetic and has relatively low electrical resistivity. This combination of properties has allowed its use in a wide variety of applications. Because the alloy displays good corrosion resistance, it has been used in food handling equipment, caustic solution, and general corrosion- magnetic and mechanical properties have enabled it to be used in devices requiring magnetic actuated parts.

Nickel 201 alloy is a low carbon modification of Nickel 200 alloy that has found applications in the electronic industry at temperatures up to 1200°F (649°C). It is preferred to nickel 200 above 600°F (315°C), because of its better resistance to "creep."

Alloy 400 – (Monel) alloy 400 is a nickel/copper alloy that is easily machined and fabricated. It is used for its excellent combination of strength, corrosion resistance, ductility and weldability. Very good in salt water and brackish water and not susceptible to stress corrosion cracking.

Alloy 600 – (Inconel) – alloy 600 is a nickel/chrome/iron alloy good in applications that require resistance to corrosion and heat. Good for a combination of high strength and good workability under a wide variety of temperatures. It is acid resistant. Used in jet engines, super heaters, food processing, steam generators.

Alloy 625 – Alloy 625 (UNS N06625) is a nickel-chromium-molybdenum alloy with excellent strength from room temperature up to about 1500°F. It maintains good oxidation resistance up to 1800°F and provides good resistance to corrosion. Some of the applications of this alloy are in chemical processing, aerospace and marine engineering, pollution-control equipment, and nuclear reactors.

Alloy 800 – (Incoloy) – alloy 800 is a nickel-iron/chrome alloy with additions of copper and moly. Has excellent resistance to general corrosion, pitting and crevice corrosion in chemicals containing chlorides and sulfuric, nitric and phosphoric acids. Used for tanks, piping, heat exchangers, pumps, valves and other process equipment.800, valves, and other process equipment. Standard product forms are round, flats, pipe, tube, plate, sheet, strip, and wire.

Alloy 825 – Alloy 825 is a titanium stabilized austenitic nickel/iron/chrome alloy with additions of copper and moly. It has good resistance to oxidizing and non-oxidizing hot acids. The moly aids in resistance to pitting and crevice corrosion. Applications include salt water cooled heat exchangers, offshore piping system tubes, heat exchangers, evaporators and scrubbers.

Alloy C-276 – (Hastalloy) C-276 is a nickel-molly-chrome alloy with the addition of tungsten. It has excellent corrosion resistance. It is suitable for most chemical process applications. It resists stress corrosion cracking is resistant to oxidation at temps up to 1900 F. A nickel-iron-chromium alloy with additions of copper and molybdenum. It also contains niobium for stabilization against sensitization and resultant intergranular corrosion. The alloy has excellent resistance to general corrosion, pitting, and crevice corrosion in chemicals containing chlorides and sulfuric, phosphoric, and nitric acids. Used for tanks, piping, heat exchangers, pumps, valves, and other process equipment. Standard product forms are round, flats, pipe, tube, plate, sheet, strip, and wire.