Copper pipe is almost pure copper manufactured to the requirements of ASTM B 42 - Standard Specification for Seamless Copper Pipe, Standard Sizes. It may be manufactured from any of five (5) copper alloys (C10200, C10300, C10800, C12000, C12200) that all conform to the chemical composition requirements of alloys containing a minimum of 99.9% Copper (Cu) and a maximum of 0.04% Phosphorous (P). Available sizes are 1/8” to 12” diameters in regular wall thickness and 1/8” to 10” in extra strong wall thickness. The standard length for copper pipe is 12 feet. Copper pipe is suitable for plumbing, boiler feed lines, refrigeration and for similar purposes.

Joints in seamless copper pipe can be threaded, flanged or brazed to fittings of the appropriate joint configuration.

Seamless Red Brass Pipe

(Red) Brass pipe is an alloy of copper manufactured to the requirements of ASTM B 43 – Standard Specification for Seamless Red Brass Pipe, Standard Sizes. It is manufactured from alloy C23000 which is comprised of approximately 85% Copper (Cu) with no greater than 0.05% Lead (Pb) and 0.05% Iron (Fe) and the remainder Zinc (Zn). Available sizes are 1/8” to 12” diameters in both regular and extra strong wall thickness. The standard length for red brass pipe is 12 feet.

Brass pipe is moderately resistant to many corrosive solutions and is often utilized for water supply and distribution. Joints in red brass pipe can be threaded, flanged or brazed to fittings of the appropriate joint configuration. Fittings in the smaller sizes, normally those below 2” diameter are, screwed cast copper alloy or brazed cup cast copper alloy. Fittings above 2” diameter are normally threaded, flanged, brazed or in some cases grooved mechanical joint fittings are employed.

Seamless Copper Tube, Bright Annealed

Bright annealed copper tube is an almost pure copper tube manufactured to the requirements of ASTM B 68 – Standard Specification for Seamless Copper Tube, Bright Annealed. It may be manufactured from any one of the following alloys: C10200, C10300, C10800, C12000, or C12200 unless specified otherwise on the original contract or purchase order. ASTM B68 tube is suitable for use in refrigeration, fuel oil, gasoline, or oil lines where the interior surface of the tube is essentially free of any scale or dirt and is specifically specified as ASTM B68.

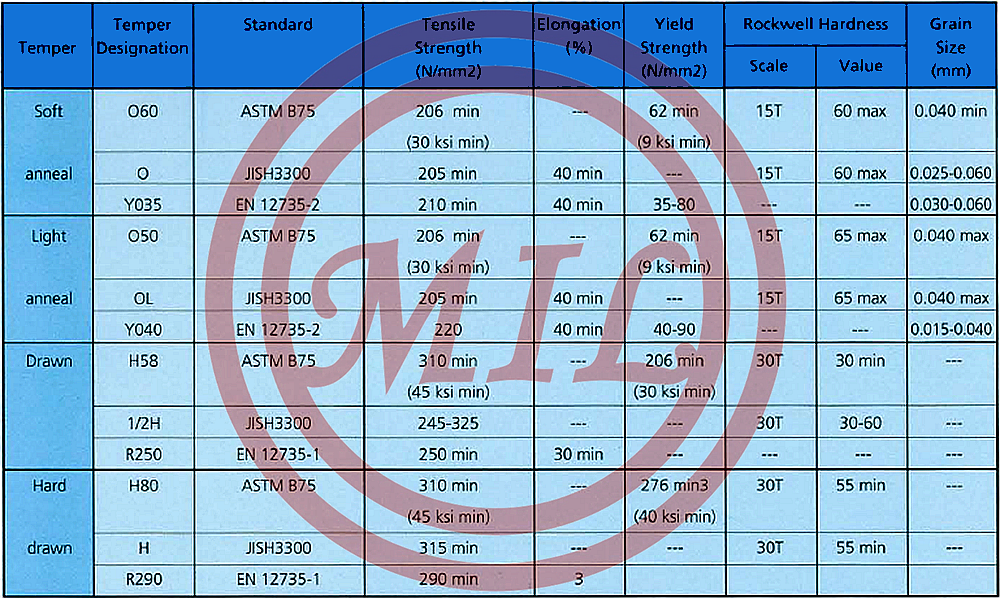

This tube is provided in annealed tempers meeting O50 – Light annealed or O60 – Soft annealed in either straight lengths or coils.

It is the responsibility of the purchaser, when ordering to provide the requirements for alloy (UNS#), temper, dimensions (diameter and wall thickness), form (straight lengths or coils), and total length or number of pieces of any particular size. It is this requirement that forces this tube to be a special order tube and not a standard stocked material. There is no specific requirements for identification of B68 tube and thus is not specifically designated as a tube permitted for use in most plumbing or mechanical codes. It is usually limited to use in specific manufacturing processes or production line type applications.

Seamless Copper Tube

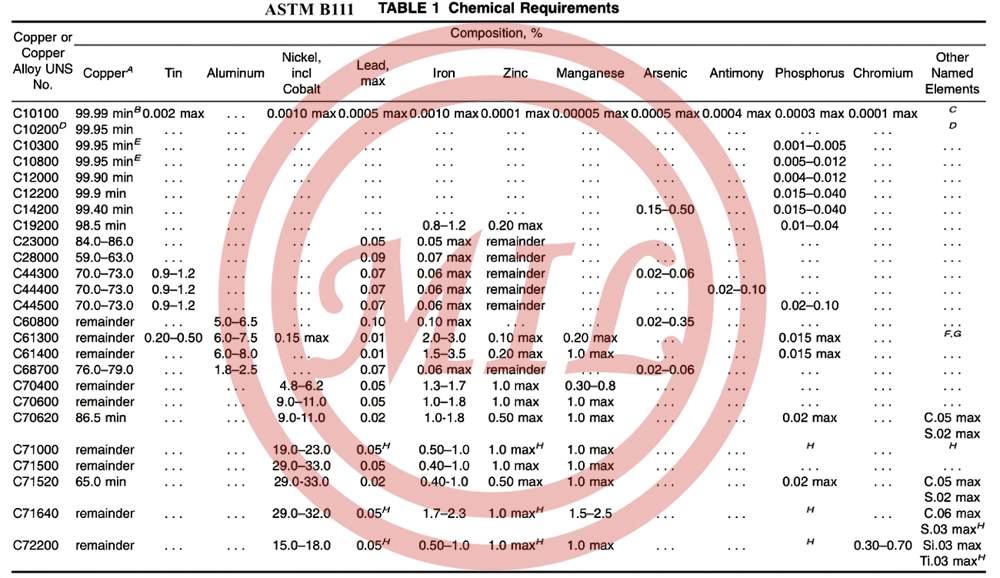

Seamless copper tube manufactured to the ASTM B 75 – Standard Specification for Seamless Copper Tube may be either round, square, or rectangular and is suitable for general engineering applications. It may be manufactured from any one of the following alloys: C10100, C10200, C10300, C10800, C12000, or C12200 unless specified otherwise on the original contract or purchase order.

Tubes meeting this standard may be furnished in any of several tempers (H55, H58, H80, O60, or O50) ranging from light drawn (usually limited to round tubes) to light annealed. It is the responsibility of the purchaser, when ordering, to provide the requirements for alloy (UNS#), temper, dimensions (diameter, wall thickness, or distance between parallel surfaces), form (straight lengths or coils), and total length or number of pieces of any particular size. It is this requirement that forces this tube to be a special order tube and not a standard stocked material.

It is usually limited to use in specific manufacturing processes or production line type applications.

Seamless Copper Water Tube

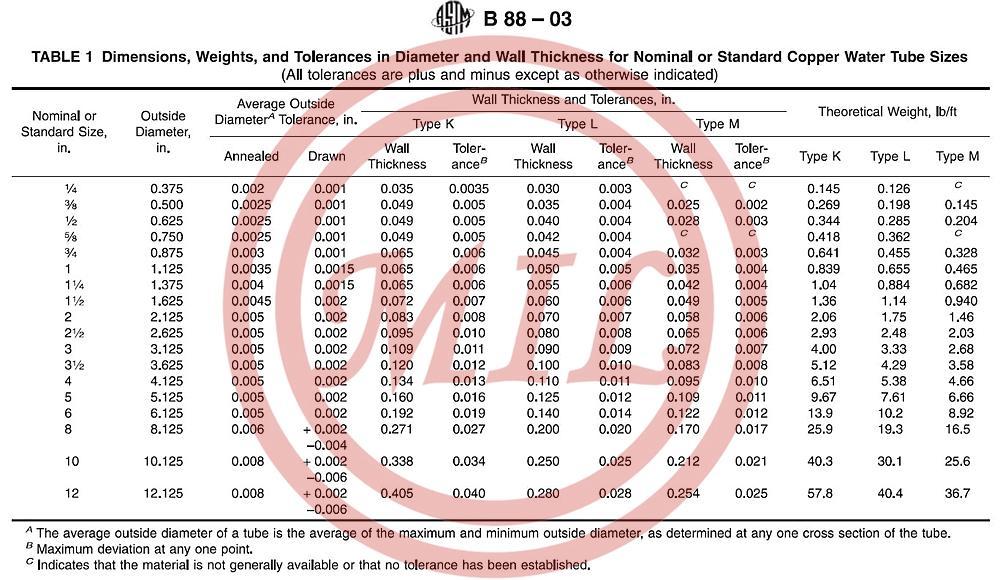

Copper water tube is a seamless, almost pure copper material manufactured to the requirements of ASTM B 88 – Standard Specification for Seamless Copper Water Tube, of three basic wall thickness dimensions designated as types K, L, and M. Type K is the thickest and type M is the thinnest with type L being of intermediate thickness. All three types of tube are manufactured from copper alloy C12200 having a chemical composition of a minimum of 99.9% Copper (Cu) and Silver (Ag) combined and a maximum allowable range of Phosphorous (P) of 0.015 % - 0.040 %.

Seamless copper water tube is manufactured in sizes ¼” through 12” nominal. Types K and L are manufactured in drawn temper (hard) ¼” through 12” and annealed temper (soft) coils ¼” through 2” while type M is only manufactured in drawn (hard) temper ¼” through 12”.

Seamless copper water tube of drawn temper is required to be identified with a color stripe that contains the manufacturer’s name or trademark, type of tube and nation of origin. This color stripe is green for type K, blue for type L and red for type M. In addition to the color stripe the tube is incised with the type of tube and the manufacturer’s name or trademark at intervals not in excess of 1½ ft. Annealed (soft) coils or annealed straight lengths are not required to be identified with a color stripe.

Seamless Brass Tube

Seamless brass tube is manufactured to the requirements of ASTM B 135 – Standard Specification for Seamless Brass Tube and may be either round, square, or rectangular and is suitable for general engineering applications. It may be manufactured from any one of the following alloys: C22000, C23000, C26000, C27000, C27200, C27400, C28000, C33000, C33200, C37000, or C44300 and these alloys contain Copper (Cu) concentrations of between 60% and 90% with various percentages of Zinc (Zn), Lead (Pb), and Tin (Sn) permitted, depending on the alloy.

Tubes meeting this standard may be furnished in any of several tempers ranging from light drawn to light annealed. It is the responsibility of the purchaser, when ordering to provide the requirements for alloy (UNS#), temper, dimensions (diameter and wall thickness, or distance between parallel surfaces), form (straight lengths or coils), and total length or number of pieces of any particular size.

Wrought Seamless Copper & Copper Alloy Tube

ASTM B 251 – Standard Specification for General Requirements for Wrought Seamless Copper and Copper- Alloy Tube covers a number of general requirements common to many wrought copper products. A few of these specifications are B 68, B75, B135, B466 and B743. Products manufactured under the requirements of ASTM B251 may be of alloys of copper, brass or copper-nickel and may be produced in any number of tempers or shapes as specified by the purchaser.

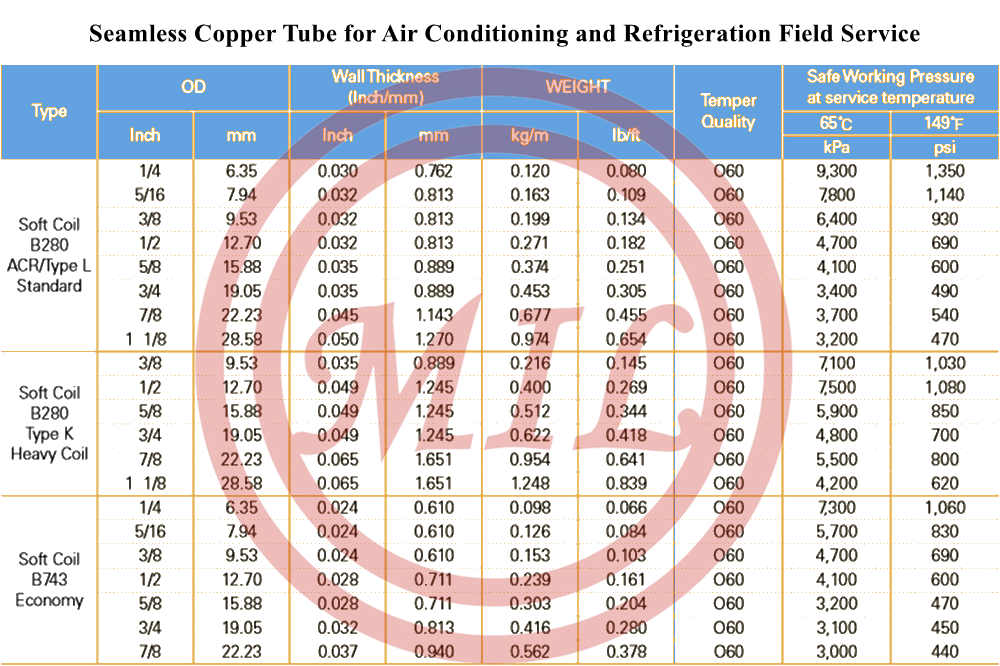

Air Conditioning & Refrigeration Tube

Copper tube used for air conditioning and refrigeration applications in the field (sometimes called “refer” or “ACR” tube) is an almost pure copper material meeting the requirements of ASTM B 280 – Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service. It is manufactured from copper alloy C12200 having a chemical composition of a minimum of 99.9% Copper (Cu) and Silver (Ag) combined and a maximum allowable range of Phosphorous (P) of 0.015 % - 0.040 %.

B 280 tube is produced in straight lengths or coils in tempers H58 or O60 respectively, although annealed straight lengths may be special ordered. Straight lengths are provided in sizes from 3/8” O.D. through 4 1/8” O.D. while annealed coils are supplied in sizes ranging from 1/8” O.D. through 1 5/8” O.D. ACR tube is required to be identified in the following fashion: Coils: The name or trademark of the manufacturer and ACR shall be permanently incised on each tube ¼” or larger at Intervals not greater than 1½ ft. Hard Straight Lengths: The name or trademark of the manufacturer and a mark indicating either L or ACR shall be incised at intervals not greater than 1½ ft. along the length of the tube. Hard straight lengths shall further be marked with a blue stripe containing the manufacturer’s name or trademark, the nation of origin, outside diameter and ACR repeating at intervals not greater than 3 ft.

Air conditioning and refrigeration tube (ASTM B 280) either coiled or straight length is further required to be cleaned and capped prior to shipping.

The maximum particulate residue limit for coils or straight lengths is 0.0035 g/ft2 or as listed in Table 2 and Table 3 of the standard.

Threadless Copper Pipe (TP)

Threadless copper pipe, often referred to as TP pipe, is a seamless copper pipe material manufactured to the requirements of ASTM B 302 – Standard specification for Threadless Copper Pipe, Standard Sizes. This pipe may be manufactured from either of two alloys, C10300 or C12200 with C12200 being the most popular. Both of these alloys are composed of copper (Cu) concentrations in excess of 99.9% thereby making this material an almost pure copper product. Threadless copper pipe (TP) is manufactured in drawn temper (hard) only and is furnished in H58 temper in nominal or standard sizes ¼” through 12”. The outside diameter of threadless copper pipe (TP) is essentially the same as schedule 40 pipe, although the wall thickness is much less than that for the same size pipe. The available lengths for threadless copper pipe is 20 foot for sizes ¼” to 10” with 12” being furnished in 15 foot lengths.

Types of Copper TubeLong lasting copper tube is a favorite choice for plumbing, heating, cooling and other systems. In the United States, it is manufactured to meet the requirements of specifications established by the American Society for Testing and Materials (ASTM).

All tube supplied to these ASTM standards is a minimum of 99.9 percent pure copper. The copper customarily used for tube supplied to these specifications is deoxidized with phosphorus and referred to as C12200 (Copper No. 122) or DHP1 Copper. Other coppers may also be used.

Table 1 identifies the six standard types of copper tube and their most common applications.2 The table also shows the ASTM Standard appropriate to the use of each type along with a listing of its commercially available lengths, sizes and tempers.

Types K, L, M, DWV and Medical Gas tube are designated by ASTM standard sizes, with the actual outside diameter always 1/8-inch larger than the standard size designation. Each type represents a series of sizes with different wall thicknesses. Type K tube has thicker walls than Type L tube, and Type L walls are thicker than Type M, for any given diameter. All inside diameters depend on tube size and wall thickness.

Copper tube for air-conditioning and refrigeration field service (ACR) is designated by actual outside diameter.

"Temper" describes the strength and hardness of the tube. In the piping trades, drawn temper tube is often referred to as "hard" tube and annealed as "soft" tube. Tube in the hard temper condition is usually joined by soldering or brazing, using capillary fittings or by welding.

Tube in the soft temper is commonlyjoined by the same techniques and also by the use of flare-type and compression fittings. It is also possible to expand the end of one tube so that it can be joined to another by soldering or brazing without a capillary fitting—a procedure that can be efficient and economical in many installations.

Tube in both the hard and soft tempers can also be joined by a variety of "mechanical" joints that can be assembled without the use of the heat source required for soldering and brazing.

STM B42-Specification for seamless copper pipe in all standard pipe sizes, both regular and extra— strong, suitable for use in plumbing, boiler feed lines, and for similar purposes.

ASTM B43-Specification for seamless red brass (Copper Alloy UNS No. C23000) pipe in all standard pipe sizes, both regular and extra—strong, suitable for use in plumbing, boiler feed lines, and for similar purposes.

ASTM B68 Specification for annealed seamless copper tube suitable for use in refrigerators, oil lines, gasoline lines, etc.

ASTM B75-Specification for seamless copper, round and rectangular including square tube suitable for general engineering purposes.

ASTM B88-Standard Specification for Seamless Copper Water & Gas Tube,Hard Drawn Temper,separated into K,L & M differentiated by a range of wall thickness.

ASTM B111-Standard Specification for Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock up to 2"(50.8mm)

ASTM B135-Specification for seamless brass round and rectangular including square copper alloy tube in straight lengths..

ASTM B188-Standard Specification for Seamless Copper Bus Pipe and Tube

ASTM B251 Standard Specification for General Requirements for Wrought Seamless Copper and Copper-Alloy Tube

ASTM B280-Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

ASTM B302-Specification for threadless, seamless, deoxidized copper pipe (TP) in straight lengths, for piping systems that are assembled with brazed-joint pipe fittings.

ASTM B306-Specification for seamless copper drainage tube (DWV) intended for use with soldered fittings for sanitary drainage, such as soil, waste, and vent piping.

ASTM B315-Standard Specification for Seamless Copper Alloy Pipe and Tube

ASTM B359-Standard Specification for Copper and Copper-Alloy Seamless Condenser and Heat Exchanger Tubes With Integral Fins

ASTM B360-Standard Specification for Hard-Drawn Copper Capillary Tube for Restrictor Applications

ASTM B372-Standard Specification for Seamless Copper and Copper-Alloy Rectangular Waveguide Tube

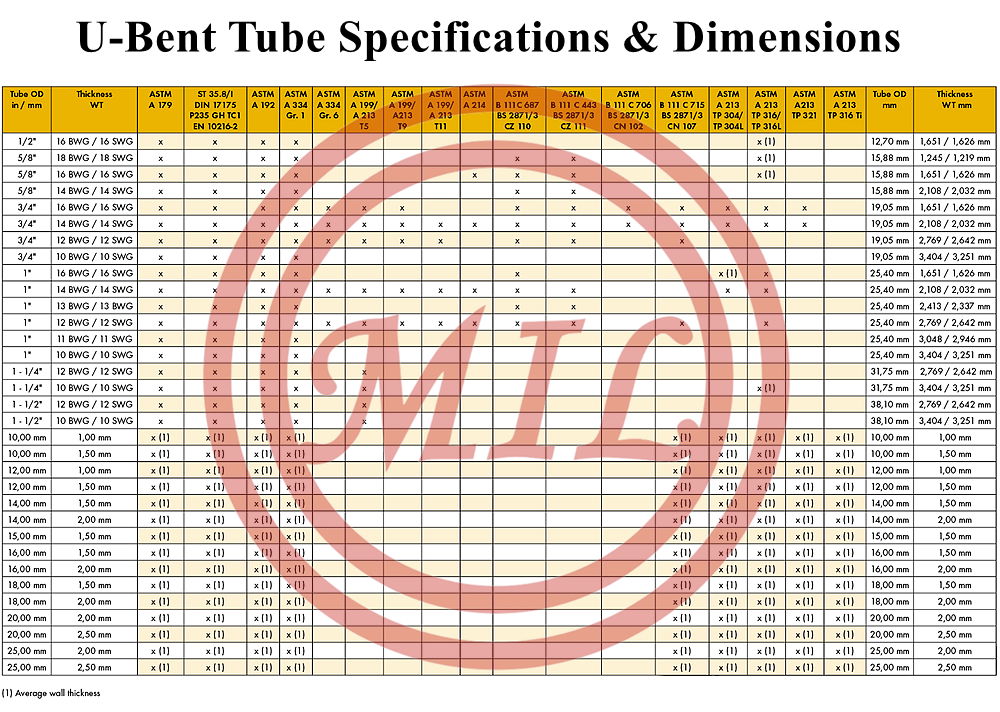

ASTM B395-Standard Specification for U-Bend Seamless Copper and Copper Alloy Heat Exchanger and Condenser Tubes

ASTM B447-Standard Specification for Welded Copper Tube

ASTM B466-Standard Specification for Seamless Copper-Nickel Pipe and Tube

ASTM B467-Standard Specification for Welded Copper-Nickel Pipe

ASTM B543-Standard Specification for Welded Copper and Copper-Alloy Heat Exchanger Tube

ASTM B587-Standard Specification for Welded Brass Tube

ASTM B608-Standard Specification for Welded Copper-Alloy Pipe

ASTM B640-Standard Specification for Welded Copper Tube for Air Conditioning and Refrigeration Service

ASTM B643-Standard Specification for Copper-Beryllium Alloy Seamless Tube

ASTM B687-Standard Specification for Brass, Copper, and Chromium-Plated Pipe Nipples

ASTM B698-Standard Classification for Seamless Copper and Copper Alloy Plumbing Pipe and Tube

ASTM B706-Standard Specification for Seamless Copper Alloy (UNS No. C69100) Pipe and Tube

ASTM B743-Standard Specification for Seamless Copper Tube in Coils

ASTM B819-Standard Specification for Seamless Copper Tube for Medical Gas Systems

ASTM B837-Standard Specification for Seamless Copper Tube for Natural Gas and Liquefied Petroleum (LP) Gas Fuel Distribution Systems

ASTM B903-Standard Specification for Seamless Copper Heat Exchanger Tubes With Internal Enhancement

ASTM B919-Standard Specification for Welded Copper Heat Exchanger Tubes With Internal Enhancement

ASTM B924-Standard Specification for Seamless and Welded Nickel Alloy Condenser and Heat Exchanger Tubes With Integral Fins

ASTM B944-Standard Specification for Copper-Beryllium Welded Heat Exchanger and Condenser Tube (UNS No. C17510)

ASTM B956-Standard Specification for Welded Copper and Copper-Alloy Condenser and Heat Exchanger Tubes with Integral Fins

ASTM B927-Standard Specification for Brass Rod, Bar, and Shapes

ASTM B950-Standard Guide for Editorial Procedures and Form of Product Specifications for Copper and Copper Alloys

AS 1432 Copper tubing for plumbing, gasfitting and drainage applications.

AS 1569 Copper and Copper Alloys-Seamless tube for heat exchangers

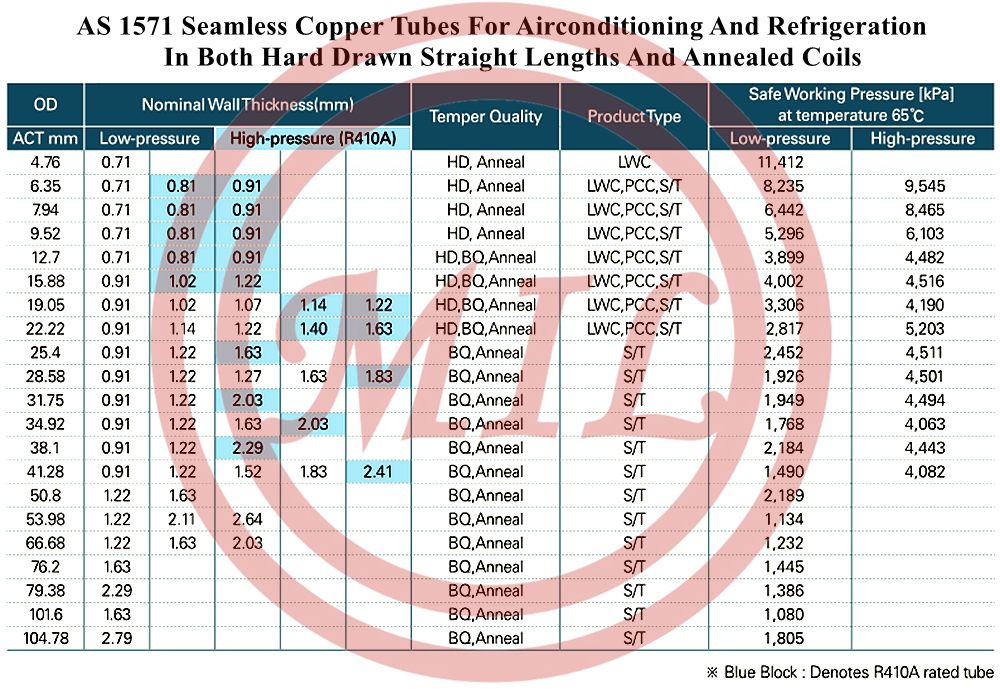

AS 1571 Seamless copper tubes for airconditioning and refrigeration in both hard drawn straight lengths and annealed coils

AS 1572 Seamless copper tubes for engineering purposes.

AS/NZS 3501 Copper Tubes for water, gas and sanitation in straight lengths, in half hard condition and in fully annealed coils.

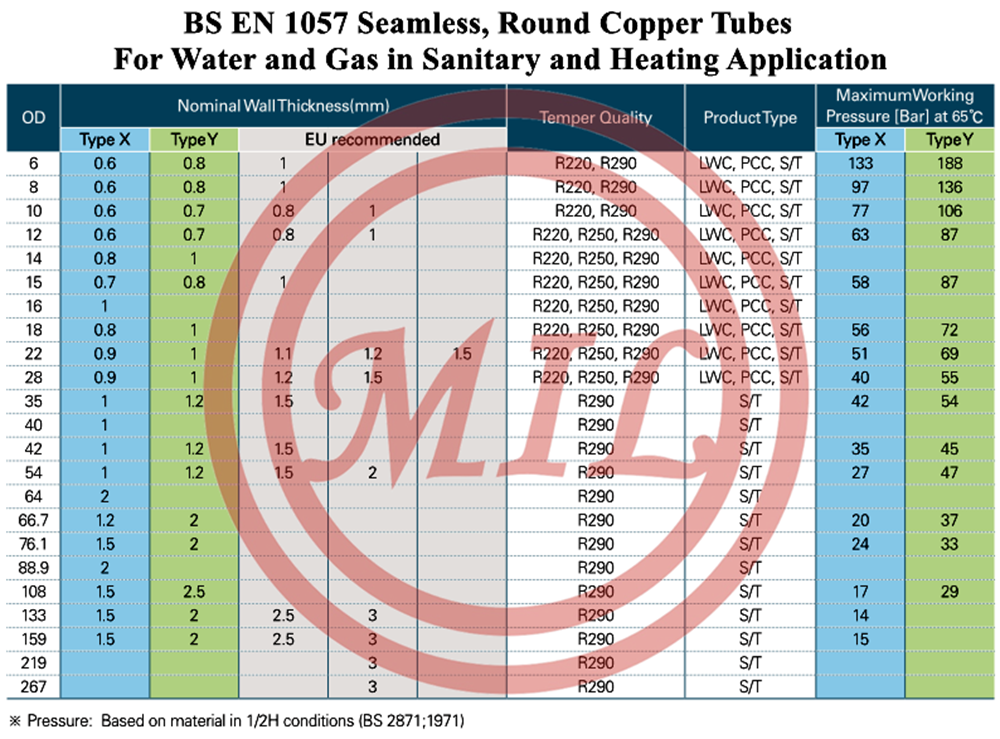

BS 2871-1 Copper and copper alloy tubes for water, gas and sanitation

BS 2871-2specification for copper and copper alloys. tubes. tubes for general purposes

BS 2871-3specification for copper and copper alloys. tubes. tubes for Heat Exchangers

EN 1057 Copper and copper alloys - Seamless, round copper tubes for water and gas in sanitary and heating applications-Dimensions

EN 12449 Copper and copper alloys. Seamless, round tubes for general purposes

EN 12450 Copper and copper alloys - Seamless, round copper capillary tubes

EN 12451 Copper and copper alloys. Seamless, round tubes for heat exchangers

EN 12452 Copper and copper alloys - Rolled, finned, seamless tubes for heat exchangers

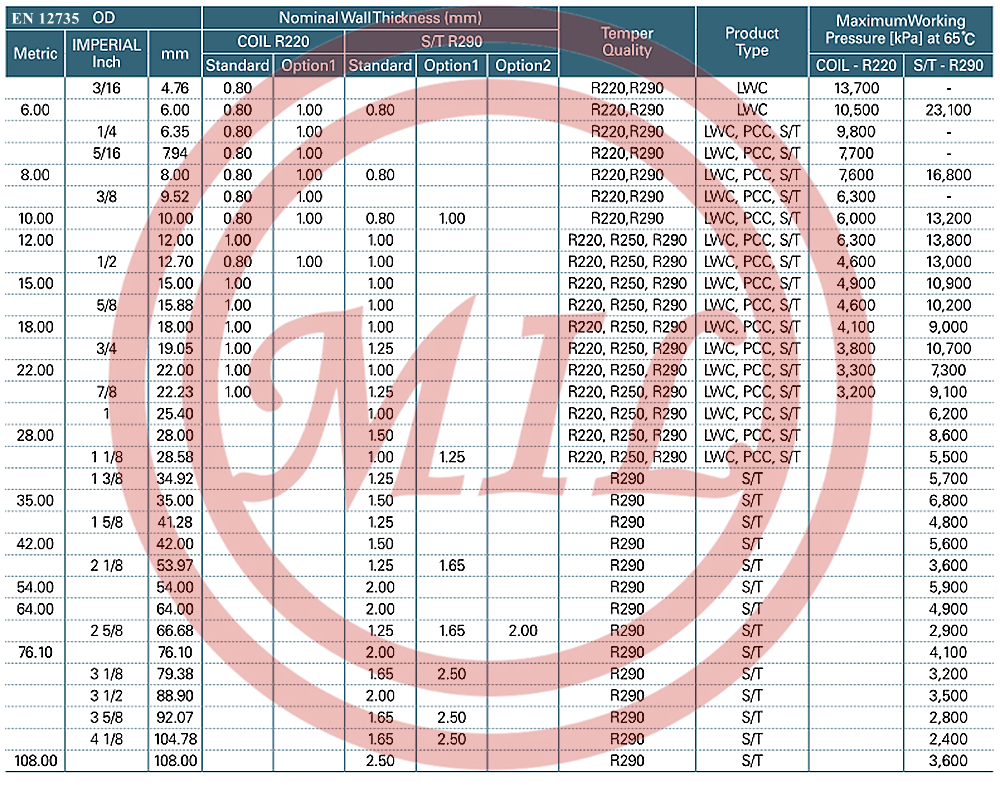

EN 12735-1 Copper and copper alloys.Seamless, round coppertubes for air conditioning andrefrigeration.Part 1: Tubes for piping systems

EN 12735-2 Copper and copper alloys.Seamless, round coppertubes for air conditioning andrefrigeration.Part 2: Tubes for equipment

EN 13348-Copper Medical Gas Pipes

EN 13600 Copper and copper alloys - Seamless copper tubes for electrical purposes

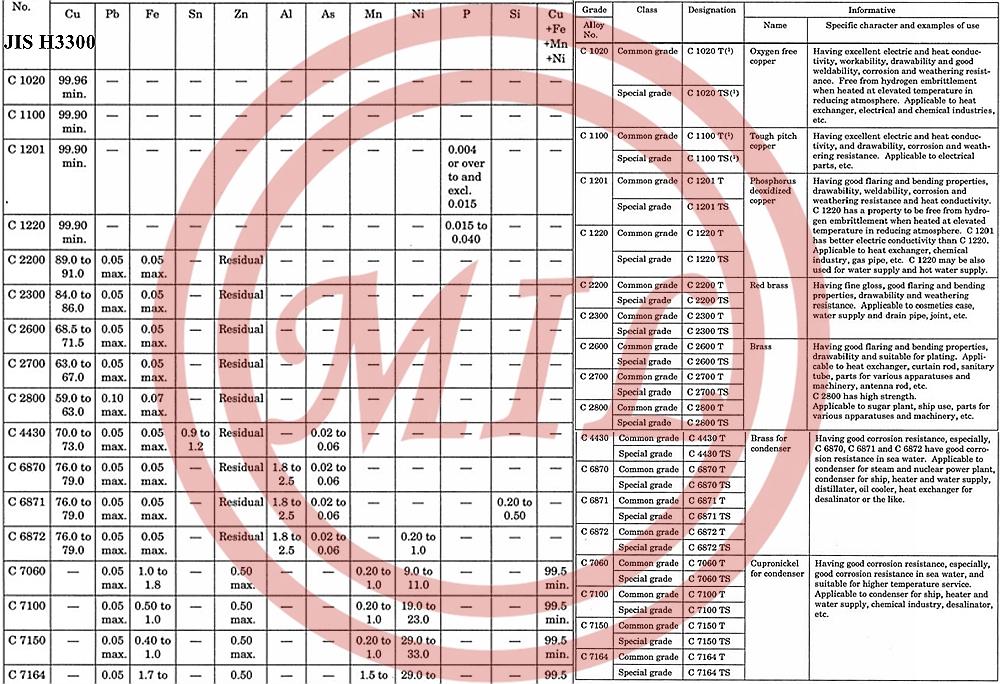

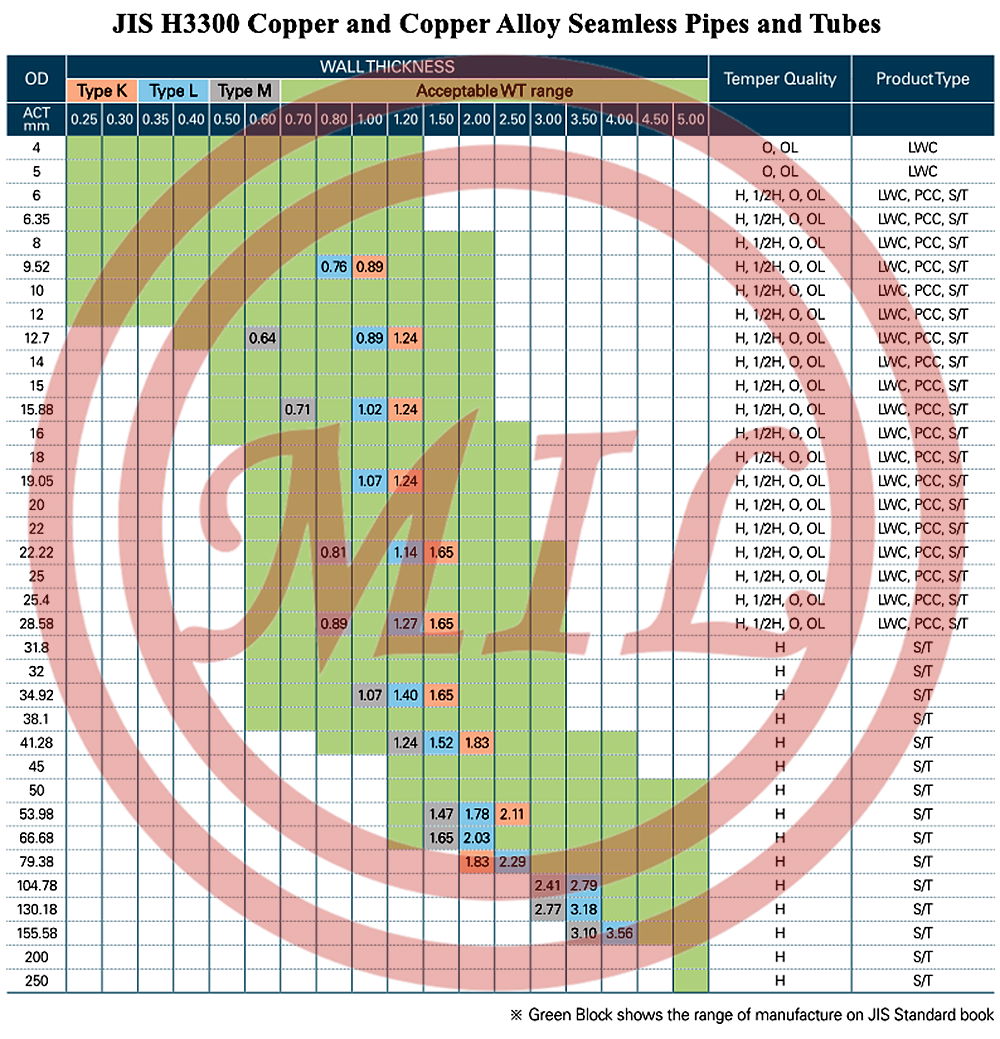

JIS H3300-2009 Copper and copper alloy seamless pipes and tubes

JIS H3330-2003 Plastic covered copper tubes

JIS H3320-2006 Copper and copper alloy welded pipes and tubes

NF A51-102-1999 Copper and copper alloys. Seamless, round tubes for heat exchangers.

NF A51-103-1999 Copper and copper alloys. Seamless, round copper capillary tubes.

NF A51-120/IN1-2010 Copper and copper alloys - Seamless, round copper tubes for water and gas in sanitary and heating applications.

NF A51-129-1999 Copper and copper alloys - Rolled, finned seamless tubes for heat exchangers.

NF A51-128-2002 Copper and copper alloys - Seamless copper tubes for electrical purposes.

SABS 460-2003/SANS 460 Plain-ended solid drawn copper tubes for potable water