|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ASTM B373,ASTM B479 1100,3003,3005,3105,5005,5052, 6061 Aluminium Foils

|

|

| Model No.︰ | - |

| Brand Name︰ | - |

| Country of Origin︰ | - |

| Unit Price︰ | - |

| Minimum Order︰ | - |

|

|

|

|

|

|

|

|

| Aluminum Foils |

| 1. Mechanical |

| The mechanical properties of aluminum foil mainly include tensile strength, elongation, and cracking strength. The mechanical properties of aluminum foil are mainly determined by the thickness. In general, aluminum foil is light in weight, good in ductility, thin in thickness, and low in mass per unit area.However, it is low in strength, easy to tear, and easy to break and produce holes when folded, so it is generally not used for packaging products alone. In many cases, it is compounded with other plastic film and paper to overcome its shortcomings. |

| 2. High barrier properties |

| Aluminum foil has high barrier properties to water, water vapor, light and fragrance, and is not affected by environment and temperature. Therefore, it is often used in fragrance-preserving packaging and moisture-proof packaging to prevent moisture absorption, oxidation, and volatilization of the package contents.Especially suitable for high-temperature cooking and sterilization packaging of food. |

| 3. Corrosion resistance |

| The surface of the aluminum foil naturally forms an oxide film. The formation of the oxide film can further prevent the continuation of the oxidation. Therefore, when the contents of the package are highly acidic or alkaline, the surface is often coated with protective paint or PE to improve Its corrosion resistance. |

| 4. Heat and low temperature resistance |

| The aluminum foil is stable at high and low temperatures, does not swell or shrink when the temperature is -73~371℃, and has good thermal conductivity, and its thermal conductivity can reach 55%.Therefore, it can be used for high-temperature cooking or other thermal processing, and can also be used for frozen packaging |

| H18 Aluminum foil |

| Aluminum is a silver-white metal, Bai, with a melting point of 660.4°C, a boiling point of 2467°C, and a density of 2.70 g/cm3. It is very light, about 1/4 of iron. It has relatively low hardness and good ductility. It can be drawn into filaments or rolled into aluminum foil. The latter is often used to pack candy and cigarettes. It also has good electrical and thermal conductivity. It is used to make wires and cables in the electric power industry and to make cooking utensils in daily life. It can form a variety of alloys with magnesium, copper, zinc, tin, manganese, chromium, zirconium, silicon and other elements. It is widely used as materials for the manufacture of aircraft, automobiles, ships, and daily necessities, as well as for the construction of doors and windows. Aluminum is one of the best reflectors for heat and light. It is used as a heat-insulating material and for making mirrors in reflecting telescopes. |

| 3003 Aluminum foil |

| Aluminum foil is a soft metal film, which not only has the advantages of moisture proof, air tightness, shading, abrasion resistance, fragrance retention, non-toxic and tasteless, etc., but also because of its elegant silver-white luster, it is easy to process beautiful patterns and various colors. Patterns are more likely to be favored by people. Especially after the aluminum foil is compounded with plastic and paper, the shielding properties of the aluminum foil are integrated with the strength of the paper and the heat-sealability of the plastic, which further improves the shielding performance of water vapor, air, ultraviolet rays and bacteria necessary as a packaging material. , Which greatly broadens the application market of aluminum foil. Since the packaged items are fully isolated from outside light, humidity, air, etc., the package is well protected. Especially for the packaging of retort food, the use of this composite aluminum foil material can ensure that the food does not deteriorate for at least one year. Moreover, heating and unpacking are very convenient, which is very popular among consumers. |

| 20mic Aluminum foil |

| Aluminum foil can be divided into hard foil, semi-rigid foil and soft foil. |

| ① Hard foil: Aluminum foil without softening treatment (annealing) after rolling, without degreasing treatment, there will be residues on the surface. Therefore, the hard foil must be degreased before printing, laminating and coating, and it can be used directly if it is used for forming. |

| ②Semi-rigid foil: aluminum foil whose hardness (or strength) is between the rigid foil and the soft foil, usually used for forming. |

| ③Soft foil: Aluminum foil that has been fully annealed and softened after rolling. The material is soft and there is no residual oil on the surface. Most application areas, such as packaging, composites, electrical materials, etc., use soft foils. |

| 10.5micron Aluminum Foil |

| Aluminum foil can be divided into thick foil, single zero foil and double zero foil according to the difference in thickness. |

| ①Heavy gauge foil ("heavy gauge foil"): A foil with a thickness of 0.1~0.2mm. |

| ②Single zero foil ("medium gauge foil"): a foil with a thickness of 0.01mm and less than 0.1mm |

| ③Double zero foil ("light gauge foil"): The so-called double zero foil is a foil with two zeros after the decimal point when its thickness is measured in mm. It is usually an aluminum foil with a thickness of less than 0.01, that is, an aluminum foil of 0.005~0.009mm. . In foreign countries, the aluminum foil with a thickness of ≤40ltm is sometimes called "light gauge foil", and the aluminum foil with a thickness of >40btm is collectively called "heavy gauge foil". |

| Aluminum Foil Cost |

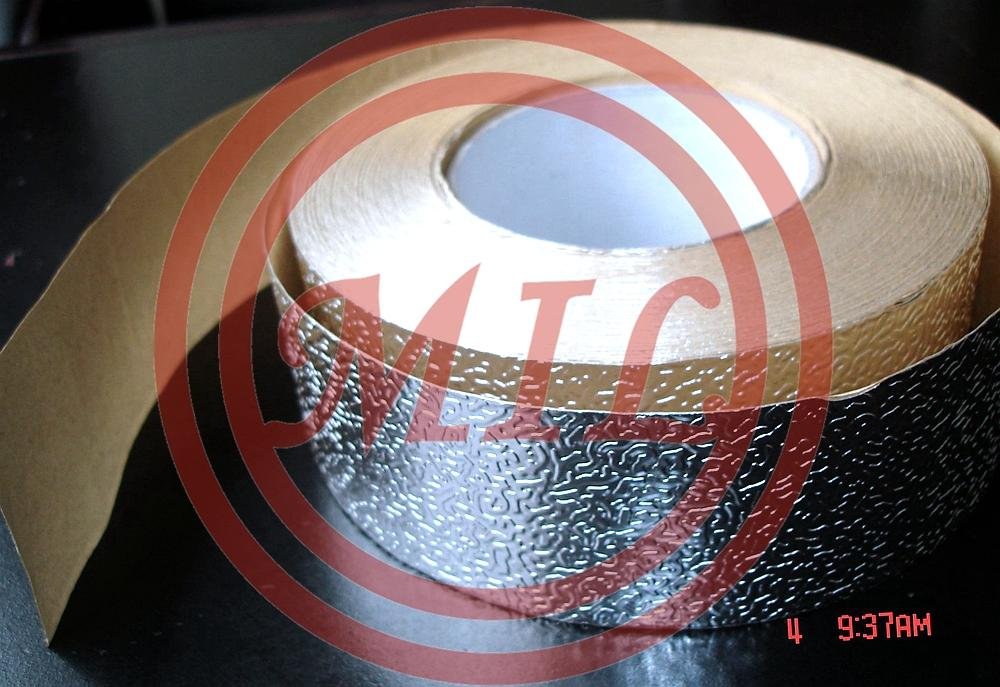

| Aluminum foil can be divided into plain foil, embossed foil, composite foil, coated foil, colored aluminum foil and printed aluminum foil. |

| ① Plain foil: Aluminum foil without any other processing after rolling, also called smooth foil. |

| ② Embossed foil: aluminum foil with various patterns embossed on the surface. |

| ③Composite foil: composite aluminum foil formed by pasting aluminum foil, paper, plastic film, and cardboard together. |

| ④Coated foil: aluminum foil coated with various resins or paints on the surface. |

| ⑤ Colored aluminum foil: single color aluminum foil is coated on the surface. ⑥Printing aluminum foil: aluminum foil that forms various patterns, patterns, characters or pictures on the surface by printing, it can be one color, up to 12 colors. |

| Aluminum Foil in microwave |

| 1. Flexibility & Reliability – With multi-plant, fully integrated production, we offer a wide range of aluminum foil specifications and features |

| 2. Meet Standard – Our aluminum foil meets mandatory standards on contact with foodstuffs. |

| 3. Aluminum foil provides a total barrier to light, color and moisture, thus making it ideal for the protection of sensitive food during cooking and storage; |

| 5. It has unique mechanical properties as it is formable, strong and can be 'dead folded', which is beneficial when wrapping food; |

| 6. Aluminum foil is an excellent conductor of heat and can withstand the highest temperatures encountered in cooking; |

| 7. After it has been used, aluminum foil can be recycled or recovered in the form of energy. |

| Craft Paper Foil |

| Due to its excellent characteristics, aluminum foil is widely used in food, beverages, cigarettes, medicines, household daily necessities, etc., and is usually used as its packaging material. When used for food packaging, aluminum foil and food paper are usually used to form composite packaging paper. Composite packaging paper has barriers Good performance, good waterproof and moisture-proof performance |

| Aluminum Foil for Insulation Material |

| The laminated aluminum foil has two beautiful silver-white surfaces, one side has a high light emissivity, and the other side is the opposite, with a soft matte finish. Based on the excellent performance and high quality of aluminum foil, double zero aluminum foil has been widely used in the following industries |

| Aluminum foil is used for thermal insulation.Aluminum foil is used as thermal insulation material outside air-conditioning ducts. In developed countries and regions, composite materials of aluminum foil, plastic and woven fiber are also used as insulation layer for building roofs. This material has thermal insulation effect. Well, it has a long service life and is an ideal building material. |

| Insulation Foil |

| Application of cable aluminum foil: In the signal line, the cable aluminum foil material is a widely used shielding material. It mainly plays the role of shielding, anti-radiation, and anti-static. The thickness of the aluminum foil has a great relationship with the shielding effect. It is difficult for interference sources with frequencies below 1GHZ to penetrate aluminum foil with a thickness of more than 38u. Of course, the shielding effect of aluminum foil is worse than that of winding, and the shielding effect of winding is worse than that of weaving, but in general, weaving and aluminum foil are at the same time Existence, because braided shielding is a mesh structure, interference sources with a certain frequency and certain wavelength will be woven to be missed, so these missing signals will be received by the aluminum foil of the cable again to achieve a better shielding effect. |

| Aluminum Foil for Transformer |

| Transformer aluminum foil and strips generally choose 1060 aluminum foil, 1070 aluminum foil and 3003 aluminum strip, which belong to the conventional series in the aluminum strip family. Series 1 and Series 3 aluminum plates are ordinary aluminum plates, and the thickness of the aluminum foil used for transformers is generally between 0.02-0.055mm. Because the product production process is relatively simple and the technology is relatively mature, it has a price advantage relative to the 5 series and 6 series products, but generally speaking, the 5 series and 6 series products are high-end products, the production process is more complicated, and the product quality is better. Better, it has good elongation and tensile strength, which can fully meet the conventional processing requirements (stamping, stretching) and high formability. |

| Aluminum Foil for Condenser |

| Electronic aluminum foil is also called electrolytic capacitor aluminum foil, which refers to the blank of the electrode foil used in aluminum electrolytic capacitors. Electronic aluminum foil undergoes chemical or electrochemical corrosion and passivation treatment to produce electrode foil (also known as chemical conversion foil), which can store electrical energy and be used as the positive and negative electrodes of electrolytic capacitors. As one of the most basic electronic components, electrolytic capacitors are widely used in electronic information industry and various electronic products of home appliances. Aluminum electrolytic capacitors have the characteristics of small size, large capacitance and low cost. In particular, the unit capacitance price is the cheapest among all capacitors. It is in line with the low-price development trend of information products and is widely used in communications, home appliances, automobiles, electronics, Aviation, new materials and other industries, the market demand is huge, and the current output of aluminum electrolytic capacitors accounts for 45% of the total output of capacitors |

| Battery Foil |

| Aluminum foil for lithium-ion batteries is usually used in the current collectors of lithium-ion batteries. Generally, most manufacturers of lithium-ion batteries use rolled aluminum foil as the positive electrode current collector. The thickness of aluminum foil for lithium ion batteries ranges from 10 to 50 microns. The commonly used aluminum foils for lithium ion batteries are mainly 1 series and 3 series. The alloy grades mainly include 1060, 1050, 1235 and 3003 aluminum foil, etc. The alloy state is O state And H state is dominant. |

| Why do lithium-ion batteries use aluminum foil as the positive electrode of the battery instead of copper foil? Both copper foil and aluminum foil can be used as current collectors. If aluminum foil is used as the negative electrode, due to the active chemical nature of aluminum, aluminum foil will be consumed first during battery discharge , This will damage the battery and reduce the battery's service life. And if the aluminum foil is used as the positive electrode of the battery, it can protect the lithium electronic battery. |

| Beer label foil |

| Beer labeling aluminum foil is mainly used for the dustproof, antibacterial and beautiful packaging of beer bottle mouths. In order to improve the quality of beer packaging and labeling production efficiency, and increase the yield of beer labels. Beer filling lines generally increase the speed of labeling, and the thickness of aluminum foil is required to become thinner and thinner, from .014mm to 0.010mm. At present, there is a trend of thinning to 0.0095mm. While the thickness is reduced, the requirements for mechanical properties are increased, and the surface quality requirements are high. Therefore, it need the production technology further improvement. |

| Aluminum Foil for Heat Sealing |

| Heat Sealing aluminum foil is suitable for sealing containers of various materials such as PET, PE, PP, PVC, PS, ABS, glass, etc. It is widely used in food, medicine, cosmetics, pesticides, motor oil, detergent, hair care products, alcohol, etc. The industry has the functions of anti-leakage, fresh-keeping, anti-deterioration, anti-counterfeiting, anti-theft and moisture-proof. The structure of the sealing aluminum foil gasket is composed of a heat-sealing layer, aluminum foil, weak adhesive layer, cardboard elastomer, etc. |

| Cap Foil |

| The yogurt cover film is mainly made of composite materials, and the structure is polyester / aluminum foil / heat seal layer (PET / AL / PE·EVA). With the continuous improvement of people’s living standards, the requirements for high quality and diversification of food and its packaging are becoming higher and higher. Cups of yogurt gradually penetrate into people’s lives. The choice of sealing materials for plastic cups of yogurt is very important. The protective effect of the product must also take into account the convenience of consumers to start drinking. Yogurt packaging must not only have good barrier properties to ensure the quality of the product, but also ensure the convenience of consumers to open while improving the grade of yogurt products. |

| Aluminum Foil for Hotel |

| 1. The surface of the aluminum foil is clean and hygienic. No bacteria or microorganisms can grow on the surface. It is a non-toxic packaging material that can be in direct contact with food and will not harm human health. |

| 2. Food packaging aluminum foil has good shading properties and is a good packaging material for products that need to avoid sunlight. |

| 3. Aluminum foil has good plasticity and can be processed into various shapes, such as square and round containers, which are convenient, safe and hygienic for holding food. |

| 4. The food container made of aluminum foil can be directly heated, and it can preserve the delicious flavor of the food without burning. |

| SRC Foil |

| SRC Foil full name is semi-rigid container foil,Aluminum foil containers have always been one of the most effective and economical ways to package food in takeaway and pre-packaging applications. These containers can be used at various temperatures and are suitable for a variety of food processing applications. They can increase the freshness of food and extend the shelf life without absorbing water or oil. Consumers can complete a series of steps such as cooking, freezing, transportation and supply in simple, safe and convenient aluminum foil packaging |

| Aluminum Foil for Cold Forming |

| Aluminum foil is clean and hygienic, with good sealing properties, and has become an important part of medical packaging. Medical aluminum foil is widely used for packaging capsules, tablets, liquids, and granules. Aluminum foil blister packaging is a packaging method in which the product is sealed between a blister formed by a transparent plastic sheet and a bottom plate (made of cardboard, plastic film or sheet, aluminum foil or their composite materials). It can be used for tablets and The packaging of capsules is also called aluminum-plastic blister packaging (PTP). |

| Aluminum-plastic blister packaging can use 8011 aluminum foil, 8021 aluminum foil, 8079 aluminum foil, etc. Due to the strict requirements on temperature and humidity for medicines, aluminum foil blister packaging has the advantages of moisture-proof, hygienic, safe and convenient, which can protect medicines from unfavorable factors during transportation and storage, thus becoming a new type of medicine packaging widely used internationally |

| Capsules Foil |

| 1. Aluminum foil has excellent moisture resistance, shading performance and extremely high barrier performance; |

| 2. The aluminum foil is safe and hygienic, non-toxic and tasteless, and can prevent the growth of bacteria; |

| 3, medicine aluminum foil packaging, convenient to carry and use; |

| 4, aluminum foil packaging can ensure that the efficacy of the drug is not affected by external factors. |

| Medicinal aluminum foil is different from ordinary aluminum foil. It has strict requirements on the material's pinhole degree, uncoiling performance and surface wettability. |

| Tablet Packing Aluminum Foil |

| Aluminum's ability to form any shape easily and its protective qualities have made it the most versatile packaging material in the world. In addition, a key benefit is that aluminium foil, aluminium cans and other aluminium packaging materials can be fully recycled and reused an infinite number of times. |

| Packaging is characterized by a simple handling simultaneously with a complete protection of the manufactured drugs. By continually developing and using new materials such as new heat seal lacquers, innovative printing processes or composite foils made from aluminium with paper, PET and other plastic |

| Blister packaging is characterized by a simple handling simultaneously with a complete protection of the manufactured drugs. By continually developing and using new materials such as new heat seal lacquers, innovative printing processes or composite foils made from aluminium with paper, |

| Two way of aluminium packing |

| Soft and hard aluminium foils are used for the cover foils of the push-through packaging. |

| Traditionally, a hard aluminium foil is used. This has only a small stretching force. This has the advantage that you can break relatively quickly and release the drug with a relatively low force. |

| If, on the other hand, a soft aluminium foil is used, more force must be applied to reach the drug because the film has a higher stretching force. Thus, a blister packaging with a cover foil made of soft aluminum is considered to be more child-resistant |

| Pharmaceutical Aluminum Foil |

| 1. The molecular density is relatively large; it can isolate water vapor and light, and the airtight type is good.Because the medicine we take is afraid of tide, oxidation, and light, aluminum foil paper is just enough. |

| 2. Better calenderability, easier to produce and disassemble. It means it's easy to break and eat. |

| 3. The surface is smooth and not easy to carry bacteria. Clean and hygienic. |

| Tobacco Foil |

| Aluminum Foil in the tobacco box can protect the tobacco from moisture, mildew and fragrance. |

| Aluminum Foil in the cigarette case is actually composite aluminum foil. Composite aluminum foil paper has high barrier properties to light, gas, and water and anticorrosion, so it can play a role in preventing moisture, mildew, and fragrance of cigarettes. |

| Aluminum Foil for Aseptic Packaging |

| With its excellent barrier characters and contributions to sealing process, aluminum foil for aseptic packaging guarantees the excellent material and filling performance of aseptic and retortable packaging. |

| Aluminum foil in packaging keeps foods fresh for months without refrigerating. It prevents the contents from losing nutritional value, vitamins or aroma – and gives total protection against light, moisture, oxygen, foreign matter contamination and damage. |

| Aluminum Foil for Chocolate Wrapping |

| Chocolate is made by fermenting cocoa beans, roasting, squeezing cocoa butter, adding milk powder, white sugar, and stirring to solidify it. Compared with other vegetable oils, cocoa butter is easier to absorb the smell. Wrap it and put it in the refrigerator, it will be contaminated with the miscellaneous smell of other foods, and aluminum foil for Chocolate Wrapping can prevent the smell. At the same time, aluminum foil for Chocolate Wrapping also has the function of heat insulation and heat preservation to prevent melting and deterioration. Sometimes a layer of hoarfrost will adhere to the surface of the chocolate. It is a phenomenon caused by the frosting effect of lipids. When cocoa butter is heated above 28 ℃, it will often precipitate from the inside and solidify on the surface of the candy, but it is harmless to the human body and does not affect the original taste of chocolate |

| Food Packaging Foil |

| Aluminum foil can't be used alone, it must be combined with plastic film. Aluminum foil food packaging bags are high-end packaging in the food industry. Aluminum foil food packaging bags have important characteristics and advantages such as high temperature resistance, puncture resistance, and non-deformation. |

| The material of the aluminum foil packaging bag is made of PE/AL/PE/CPP combined with each other, PE printing effect is good, AL barrier performance is strong, opaque, PE ordinary packaging inner layer, CPP high-temperature cooking inner layer. When the aluminum foil is used, the purity of the material is very high, it must reach 99.99%, and there is almost no impurities. However, because of the small pores in the aluminum foil, it is rarely used alone, and it must be used together with the plastic film. |

| Baking Tin Foil |

| When people say Baking Tin Foil,that is mean Aluminum foil 8011,Aluminum alloy 8011 foil is the most widely used metal in our daily lives. It has the characteristics of high temperature resistance, keeping the original smell of food, light weight, corrosion resistance, and easy maintenance of the end product. 8011 aluminum foil is also the best choice for baking tin foil. |

| Tin Foil Aluminum Foil |

| A film-like metallic paper coated or pasted with silver, mostly silver-white,Tin Foil Aluminium foil, also known as aluminum foil, is also called tin foil in Hong Kong. It is a thin sheet with a thickness of less than 0.2mm that is processed by an aluminum foil rolling machine. It is mainly used for kitchen cooking, food, or Used to make some materials that can be cleaned easily. Thousands of tons of aluminum foil are used all over the world to protect and package food, cosmetics and chemicals. |

| Although it is called tin foil, it is actually not paper but aluminum foil, made of aluminum. The middle is aluminum, and the hot stamping material is directly calendered into thin sheets with metal aluminum. Its hot stamping effect is similar to that of pure silver foil, so it is also called fake silver foil. Because of the color and luster, people in the southern region are called tin foil. Because aluminum has a soft texture, good ductility, and silver-white luster, if the rolled sheet is mounted on offset paper with sodium silicate and other materials to make aluminum foil, it can also be printed. Generally used in tobacco, high-grade confectionery food. |

| Kitchen Foil |

| Kitchen Foil can be described as an attractive cooking tool in the kitchen. It can not only accumulate heat, make food absorb energy faster and shorten the cooking time, but it can also save this heat without being affected by the outside world. Foil in the kitchen is An indispensable powerful helper. |

| Kitchen foil is often used in kitchen cooking. It is generally used in ovens. It is made of an alloy. Kitchen foil is divided into photosensitive surface and matte surface. Usually, the matte surface is in contact with food and the photosensitive surface is outside. It helps food evenly heat during cooking and prevents food from scorching. It is also very suitable for outdoor, home barbecue, baking and other cooking. |

Reference Standards:

ASTM B373 Aluminum Foil for Capacitors

ASTM B479 Annealed Aluminum and Aluminum-Alloy Foil for Flexible Barrier, Food Contact, and Other Applications

|

|

|

|

Product Image

|

|

3004 Aluminum Foil

Automotive Condenser Aluminium Foil Roll Thin Narrow 35mm Width

Aluminum Foil Bubble Thermal Wrap Insulation

Embossed Aluminum Foil/Tape

Orange peel embossed aluminum foil for PIR Foam Pre-insulated Duct Panel

Aluminum Foils For Food Package or Pharmaceutical Canules

Full Pan Aluminum Foil Containers

|

|

|

|

|

|

Related Products

|

|

|

|

|

|

|

|

|