|

Steel Grating Steel Grating

|

| |

|

|

|

|

|

|

|

|

Steel grating is a metal structure with welding or pressure locked. We mainly introduce processing and major parameters of the two types of steel grating (welded and locked).

Steel Grating Structure and Processing Technology:

Steel grating is a kind of square opening steel structure welded or plugged with flat-rolled steel and cross bars lined and crossed with certain spacing. Steel grating has good ventilation, lighting, cooling, slip-proof properties. Mainly used to make steel structure platform plates, steel ladder treads, steel grating fence and drain covers and so on.

Steel grating can be divided into two major types according to processing methods: pressure welding and pressure locked.

Welded steel grating technical parameters:

1.Material:

① Flat-rolled steel: high quality low carbon steel, stainless steel, aluminum alloy steel.

② Cross Bar: Q235A or optional 304 stainless steel twisted steel, square steel, round steel, flat steel.

2:Flat Bar Surface Shape: flat, serrated, I -shaped, toothed.

3:Flat Bar Specification:

① Plane Flat Bar Specification:

a Thickness: commonly 3mm and 5mm;

b Height: commonly 25mm, 30mm, 32mm, 40mm, 45mm, 50mm, 60mm and so on.

① I -shaped Flat Bar Specification:

a, Thickness of both ends: 5mm;

b, Thickness of the center: 3mm;

c, Height: commonly 25mm, 32mm, 38mm, 44mm, 50mm and so on

4.Flat Bar Spacing: Two adjacent center bearing bar distance , commonly three sizes: 30mm, 40mm, 60mm. Dense steel grating spacing is less than 25mm. Steel grating is mainly used for demanding applications.

5. Cross Bar Specification: common specifications: 5 × 5,6 × 6,8 × 8mm.

6. Cross Bar Spacing: Center distance between two adjacent bar is typically 50mm, 100mm

7. Length of Steel Grating Panel:. General steel grating length ≥ 800mm. Trench cover for large span platform has a length of 3000-10000mm.

8. Surface Treatment: Electro-galvanized, hot galvanized , painting, dipped rust-proof oil. These treatment can play a role in preventing oxidation.

9. Steel Grating Shape: Square steel grating , rectangular steel grating , steel grating with round edging , V- groove decking , profiled steel grating , fan-shaped steel grating combined into hollow circular plate, semicircular steel grating , special shaped steel lattice panels, profiled steel grating

10. Packaging Methods:

① Strap Packaging: Generally for relatively common shape steel grating .

② Pallet Packaging: General packing for export.

③ Screw Rod Fixation: Using four screws through the steel grating aperture, locking screw packaging method .

Bundled neatly packaged steel grates with a packing strap, steel grating packed into pallet, steel grating packed with screw locking rod, steel grating packed with screw locking rod.

Pressure locked steel grating technical parameters:

The crossing bar of standard pressure lock steel grating bar is usually 20 × 5mm flat steel ( or other specifications ) , pushed by strong pressure into the bearing flat steel. The jointing spots between flat steel bars are locked by the pressing force yielded through deformation. The steel bar can be made of ordinary steel, aluminum or stainless steel.

Pressure Locked Steel Grating Type: Total four types: ordinary type, the integral type, shade -type , heavy-duty.

1. Common Type:

① After bearing flat steel bar grooving, the crossing flat steel bar pressure locked.

② Ordinary steel grating maximum working height: 100mm.

③ Steel grating length is usually less than 2000mm.

2. Integral Type:

① Flat bearing flat steel bar and crossing bars have the same height, grooving depth is 1/2 of that of bearing flat bar.

② Steel grating panel height: max. 100mm.

③ Steel grating panel length is usually less than 2000mm.

3. Shading Type:

① Flat bearing bar grooving at 30°or 45°, then pressure locked.

② Other spacing and specifications according to different needs.

③ Grating panel height is less than 100mm.

4. Heavy Loading Type:

② The bearing flat steel bar and the crossing bar pressure locked under pressure of 1200 tons.

② Suitable for big span heavy loading applications.

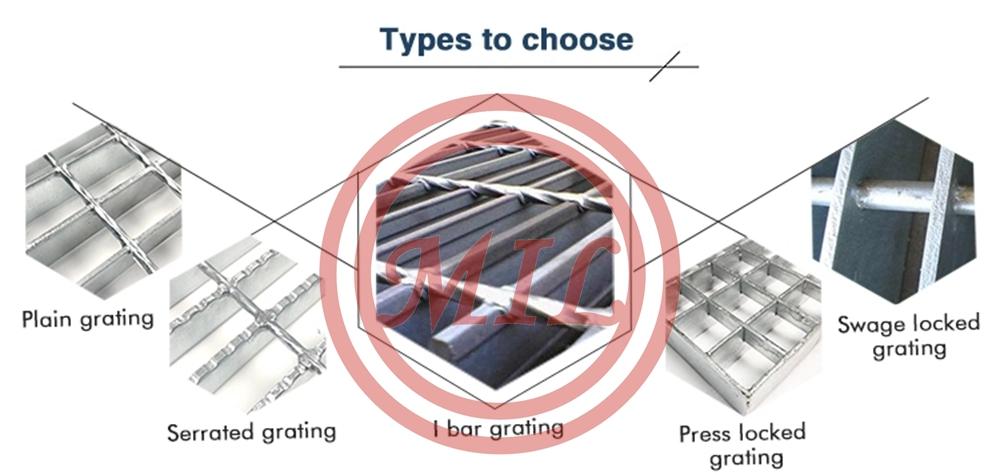

Types of Bearing Bar

Steel grating is perfect for factories, buildings. generating plants; in fact anywhere the ease of movement and safety is required.

With steel grating quick fitting accessories, ease of cleaning, safety and strength will provide you with the economical answers to lots of applications.

Because of its robust design and spanning abilities, steel grating is very strong and safe for the support of floors and elevated walkway.

Types of bearing bar

(1) Flat Type: (2) Serrated Type: (3) I Bar:

Flat bars can be made from steel strip or slit sheet or from rolled. Serrated type grating offers users a slip-free surface. It is available with most of the standard bearing bars. An extruded bearing bar having a cross sectional shape resembling the letter "I".

(4)Press-locked steel bar grating

Press-locked steel bar grating is often desirable because its smooth look, clean and excellent support. It exhibits the same strength, long life and openness as welded grating. Materials include mild carbon steel and stainless steel. It is also available in a serrated surface for extra safety.

Spacing range can be custom designed to meet the requirements. This method of manufactureing is particularly flexible that it allows for the production of grating with custom bearing bar spacing. Small quantities can easily be manufactured to suit the precise needs of most applications.

* Specification :

MATERIAL

Mild Carbon Steel:

Mild carbon steel provides an economical, high strength for uses in most industrial and commercial applications. The load bearing bars are produced from steel which conforms to the following equivalent standards: JIS G3101 SS400 or ASTM A36 or equivalent.

Stainless Steel:

Stainless bar grating is a choice for corrosive environments such as chemical, food and hydro processing areas. It is available in welded and press locked as well as in many bearing bar sizes. The most common material is Type 304 (SUS304), however, Type 316 (SUS316) or Type 316L (SUS316L) is also available. 304 stainless steel is the most popular type contains both chromium and nickel to provide excellent balance resistance and workability. 316 stainless steel is better corrosion, pitting resistance and higher strength at elevated temperatures than 304. 316L is extra low carbon variation of 316 to avoid carbide precipitation due to welding.

SURFACE TREATMENT:

Untreated

Allowing quicker delivery to customers whom fabricate and galvanize the grating on their own.

Galvanized

Hot Dip Galvanizing can give a hygienic and clean maintenance free bright finish. The minimum average hot dip galvanized is coated as required by Standards AS1650, BS729 and ASTM A123.

Galvanized Steel Grating, Removable

Galvanized steel grating plates:

Steel plates welded on certain flat steel bar and spacing with the high-pressure welding machine welded together is called steel gratings. The cutting, incision, opening, the package-processing procedures are necessary as customer demand for the finished product. Its characteristics include high-intensity and light structure. The grid is a firmly welded steel bar structure with a high capacity, light structure, easy loading and other characteristics like aesthetic appearance. The hot-dip zinc surface treatment gives it a good anti-corrosion capacity, shiny surface appearance and durability for uses. It is suitable for places and sites requiring ventilation, explosion proof, lighting resistance, heat resistance materials. Widely used in the petrochemical industry, power plants, waterworks, sewage treatment plants, municipal works, sanitation projects in areas such as platforms, corridors, bridge, ditch cover, well covers, ladders, fences, rails, and so on.

Steel Grating is made by stainless or mild steel of certain sizes through the processing of grooving, lock-pressure, welding, finishing and other treatment. Industrial bar gratings can be actually made from copper, aluminum and other materials, while galvanized steel grating is the mostly used one due to its economic cost and good property.

Steel grating, with robust design and spanning abilities, is very strong and safe for the support of floors and elevated walkway. It can be used for ceiling, interior decoration, decoration, platform aisle, ventilation windows, (Wells), advertising plaque and other construction.

Materials:

Mild carbon steel provides an economical, high strength for uses in most industrial and commercial applications.

The advantages, specific application and features of steel grating:

Steel grating offers the following advantages compared with steel grid sheets:

Steel grating has light weight, good strength, large carrying capacity and can save materials and cost. It offers good ventilation of light and wind, a modern sense, aesthetic appearance and anti-skid safety. It is also easy to clean, easy to installation and durable for uses.

Steel grating products are designed and manufactured for various industrial and civil constructions in city road, gardens, yard, airport, railway and industrial engineering, and they offer the following the features:

Aesthetic outlook: Simple lines and silver appearance meeting the modern trend.

The best drainage: Leakage area of 83.3 percent, more than twice of cast iron products.

Hot-dip galvanized treatment: Good rust-proof property, maintenance-free replacement.

Anti-theft design: The cover and the frame is joint with hinge offering security, safety and open convenience.

Savings investments: Large-span. Less lost for heavy load compared with cast iron products. Cost can be saved for the risk of being stolen or crushing one if cast iron is uses.

Press-locked Steel Bar Grating

Pressure lock steel grating is a kind of high strength grating. It is a product featuring unique combination of uniformity and precision. It has light structure, elegant style, beautiful and natural design and it is maintenance-free. Press-locked steel grating is used in civilian and commercial buildings, theatres, subway, suburban railway, and other municipal engineering.

It exhibits the same strength, long life and openness as welded grating. Materials applied include mild carbon steel and stainless steel. It is also available in a serrated surface for extra safety.

Stainless Steel Grating

Stainless steel bar grating is a choice for corrosive environments such as chemical, food and hydro processing areas. It is available in welded and press locked as well as in many bearing bar sizes.

Materials: The most common material is Type 304 (SUS304), however, Type 316 (SUS316) or Type 316L (SUS316L) is also available. 304 stainless steel is the most popular type contains both chromium and nickel to provide excellent balance resistance and workability. 316 stainless steel is better corrosion, pitting resistance and higher strength at elevated temperatures than 304. 316L is extra low carbon variation of 316 to avoid carbide precipitation due to welding.

Uses: Stainless steel bar grating is mainly used in chemical industry, food processing, hydro processing and other industries as listed:

Aluminum Grating

aluminum grating is designed to be a high-strength, low-weight product that uses an I-bar or rectangular bearing bar with cross rods hydraulically swaged under high pressure. Thus, giving you a rigid, virtually maintenance-free flooring product.

Similar to steel grating, aluminum grating can be pressure locked as an alternative to swage locked. This application process also allows the customer to choose a close mesh grate where certain special needs are to be met.

Fiberglass Grating

Our fiberglass grating is available in molded and pultrusion styles. Molded grating is manufactured by interweaving continuous glass filaments which are impregnated with a thermosetting resin. Up to five grid patterns are available in panel sizes 3’ x 10’ and 4’ x 12’.

Pultrusion is a continuous molded process in which glass roving and matting are pulled through a vinylester or polyester resin bath. Standard panels are 4’ x 4’, 4’ x 10’, 4’ x 12’, 4’ x 20’, 3’ x 10’ and 3’ x 20’.

The molded and pultrusion grating styles are available with anti-skid surface, fire retardant corrosion resistant, U.V. protected, non-conductive and are lightweight.

Additionally, we offer fiberglass structural shapes produced in more than 100 configurations. Fiberglass structural shapes are widely used in industrial construction, maintenance, as components for industrial equipment, and commercial products.

If any inquiry, please specify the following index for your requirements:

Height of End Plate (H);

Pitch of Cross Bar (CP);

Width of Grating (W);

Length of Grating (L);

Thickness of Bearing Bar (T);

Pitch of Bar (PB);

Height of Bearing Bar (H).