Induction Bending is a controlled means of bending pipes through the application of local heating using high frequency induced electrical power. to create a narrow, circumferential, heated band around the material to be bent. When the appropriate temperature is reached, the material is pushed forward through the coil at a consistent speed and temperature while a bending moment is applied. After the material passes through the coil, it may be cooled (quenched) by forced air or water spray, or it may be allowed to cool naturally at ambient temperatures.

Originally used for the purpose of surface hardening steels, induction technology when used in pipe bending consists basically of an induction coil placed around the pipe to be bent. The induction coil heats a narrow, circumferential section of the pipe to a temperature of between 850 and 1100 degrees Celsius (dependant on the material to be formed). As the correct bending temperature range is reached, the pipe is moved slowly through the induction coil whilst the bending force is applied by a fixed radius arm arrangement.

As the bending occurs, the adjacent area forward of the heat band is water or air quenched (or may be allowed to cool naturally) thereby allowing the cool material to either side of the ‘heat band’ to retain the integrity of the original material as best as possible. This means of distortion control provides excellent dimensional accuracy and repeatability.

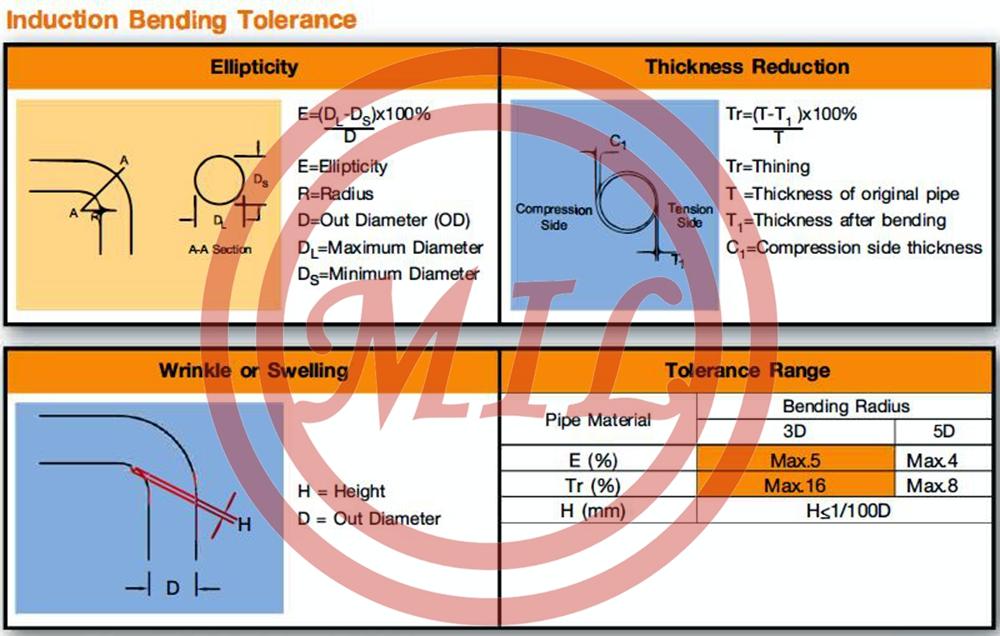

Achieved tolerances when forming induction bends are to some extent governed by the materials in hand and the required format of the finished product however the following are the minimum standards to which Induction Pipe

Although induction bending produces excellent results as far as physical properties are concerned, it must be noted that there are two important considerations required – firstly the reduction in wall thickness at the outside (extrados) of the bend and secondly the degree of ovality which is present.

The induction pipe bending process uses induction heating to produce highly accurate bends. The quality of induction bends is superior to the elbow fitting. Hydro burst tests show that spools with induction bends fail in the straight pipe and not in the bend, whereas in comparable elbow-based systems the elbow (inside radius) is always the first to burst. Stress calculations confirm this. The natural tendency to have a thicker inside wall thus proves to be advantageous and ensures that the bend exceeds the strength of the straight pipe. Many companies have exclusively chosen equipment for their induction bending.

Destructive Mechanical Testing

Tensile testing (ASTM and BS EN)

Impact testing (ASTM, BS EN & IZOD) from ambient to – 196° C

Hardness Testing (Vickers and Brinell)

Corrosion tests on Duplex and Stainless steels to ASTM G48 – A

Macro and Micro examinations of metallic materials (Including both photo macro & micrographs)

Determination of percentage ferrite to ASTM E562

Weld testing (complemented by our NDE availability)

Non Destructive Examination

■Magnetic particle inspection – standard format

■Magnetic particle inspection – fluorescent format

■Liquid penetrant inspection

■UT wall thickness survey

■UT straight beam lamination survey

■UT shearwave survey

■UT longitudinal seam weld survey

■Surface hardness survey

Post Bend Heat Treatment

Reference Standards:

ASME/ANSI B16.9 Butt welded fittings made of worked steel – bends, tees and elbows

ASME B16.49 Factory-Made Wrought Steel Buttwelding Induction Bends for Transportation and Distribution Systems

EN 13480 Metal industrial pipelines, inspection and tests - bends

ISO 15590-1/EN 14870-1 Petroleum and natural gas industries - Induction bends, fittings and flanges for pipeline transportation systems - Part 1: Induction bends

DEP 31.40.20.33-Gen Linepipe induction bends (amendments/supplements to ISO 15590-1)

DVGW G463 Steel mains in gas pipelines of operating pressure above 16 bar - bends,

TOTAL GS EP PLR 221 Fabrication of hot bends for pipelines (sweet service)

ABNT 15273 Petroleum and Natural Gas industries - induction Bends tor Pipeline Transportation Systems(Brazilian standard on induction bending for the oil and gas industries)